Analysis method for determining calcium carbide in composite silicon carbide deoxidizer for steelmaking

A technology of calcium carbide and analysis method in silicon carbide deoxidizer, which is applied in the field of steelmaking, can solve problems such as the inability to accurately measure calcium carbide content, and achieve the effects of short measurement time, rapid analysis, and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

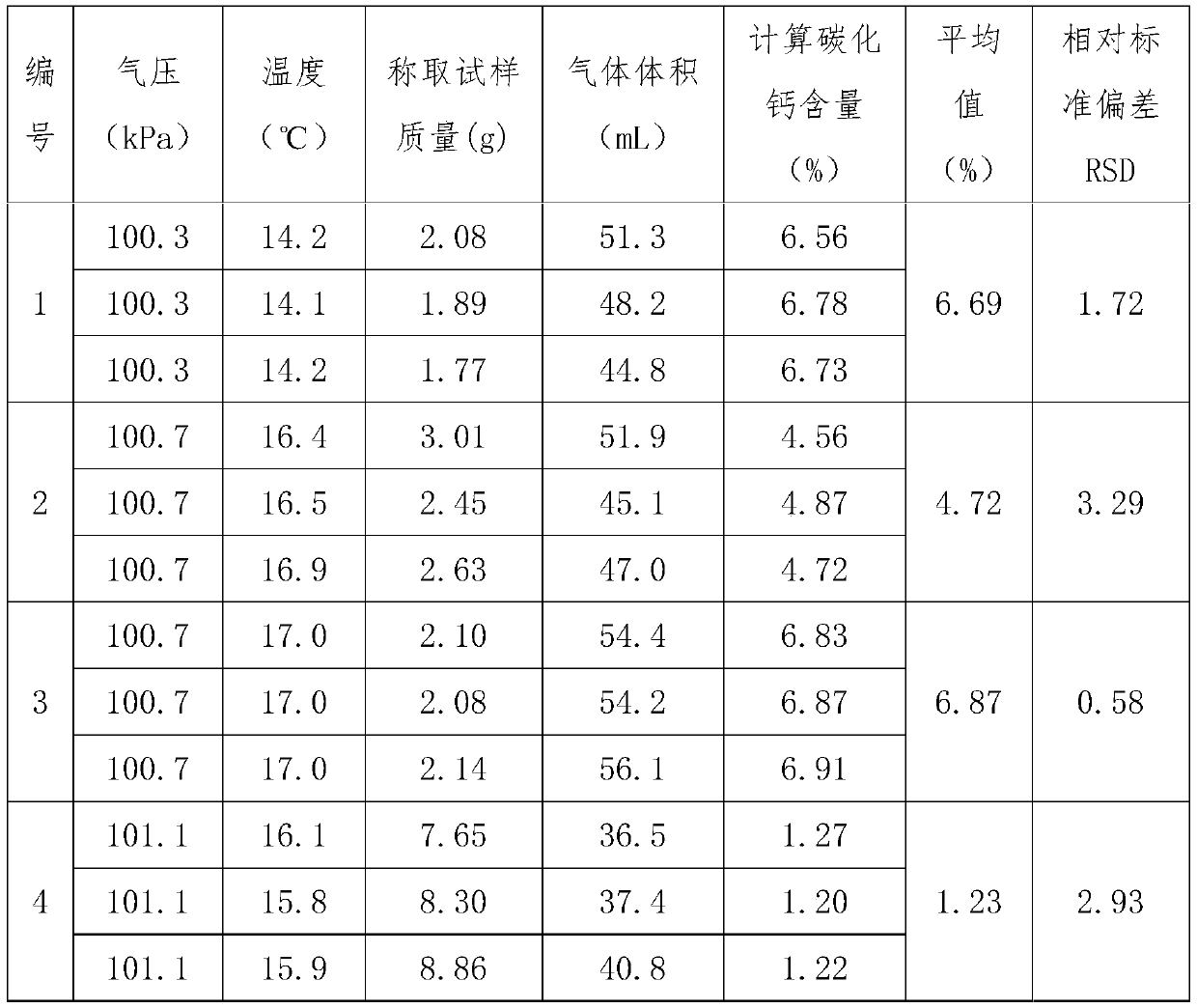

Examples

Embodiment Construction

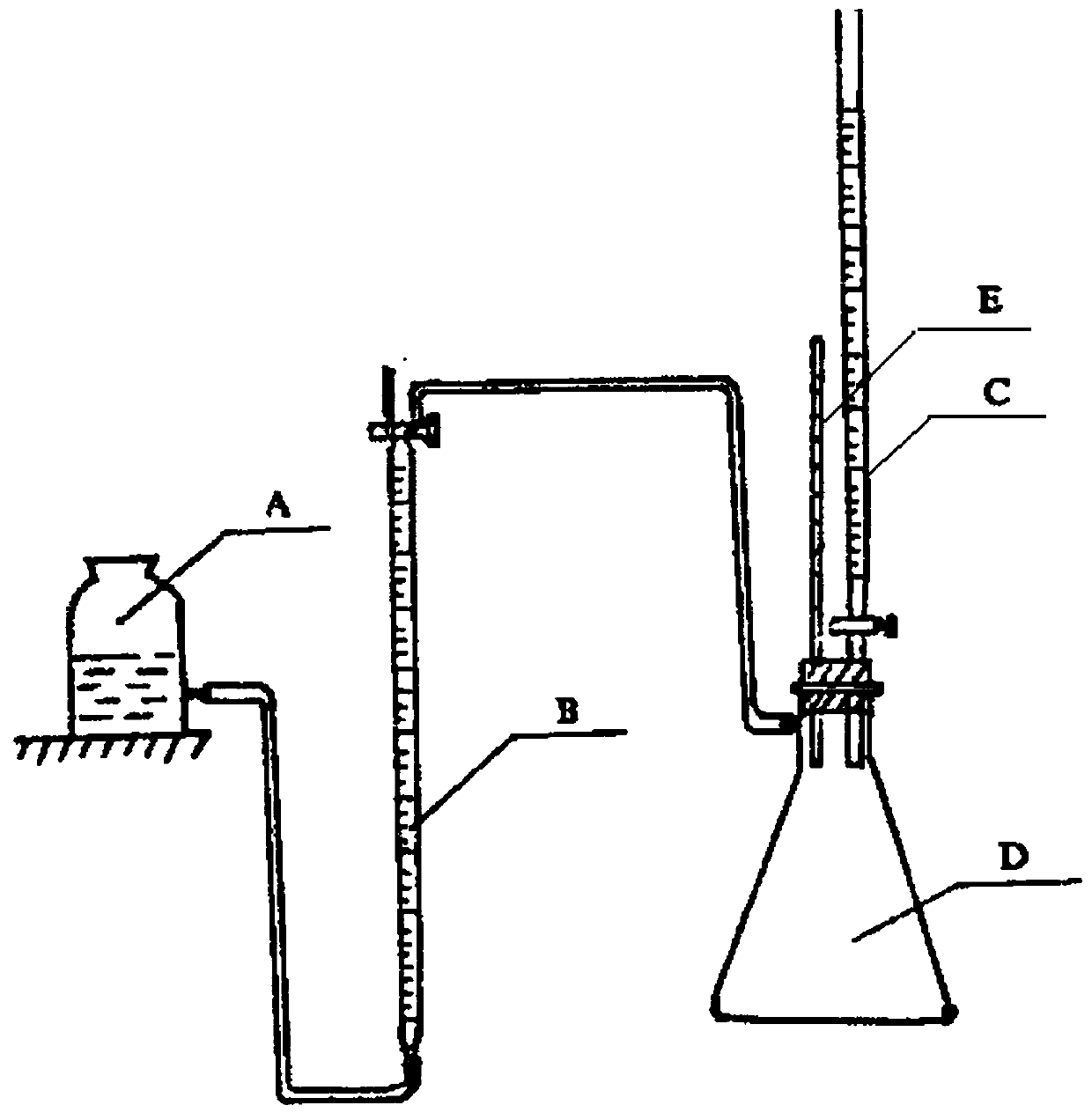

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

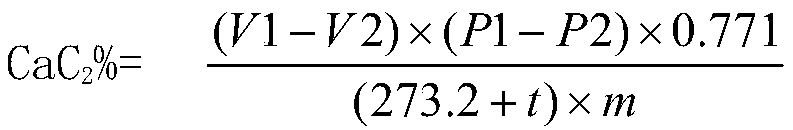

[0036] The method for measuring calcium carbide content in composite silicon carbide deoxidizer for steelmaking of the present invention comprises the following steps:

[0037] Step one, preparation work.

[0038] 1 Pass acetylene gas into saturated sodium chloride solution for ten minutes to prepare saturated acetylene sodium chloride solution (because the saturated vapor pressure of acetylene sodium chloride saturated solution is only 75% of water, it can effectively reduce the influence of water vapor imbalance, and help reduce the solubility of acetylene in water).

[0039] 2 Check the tightness of the analysis and detection device: connect the analysis and detection device, add saturated acetylene sodium chloride solution into level bottle A, and tighten the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com