Waste refrigerant recycling and adjusting device based on weight change

A refrigerant recovery and weight change technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as increased production costs, high power consumption, and environmental ozone layer destruction, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

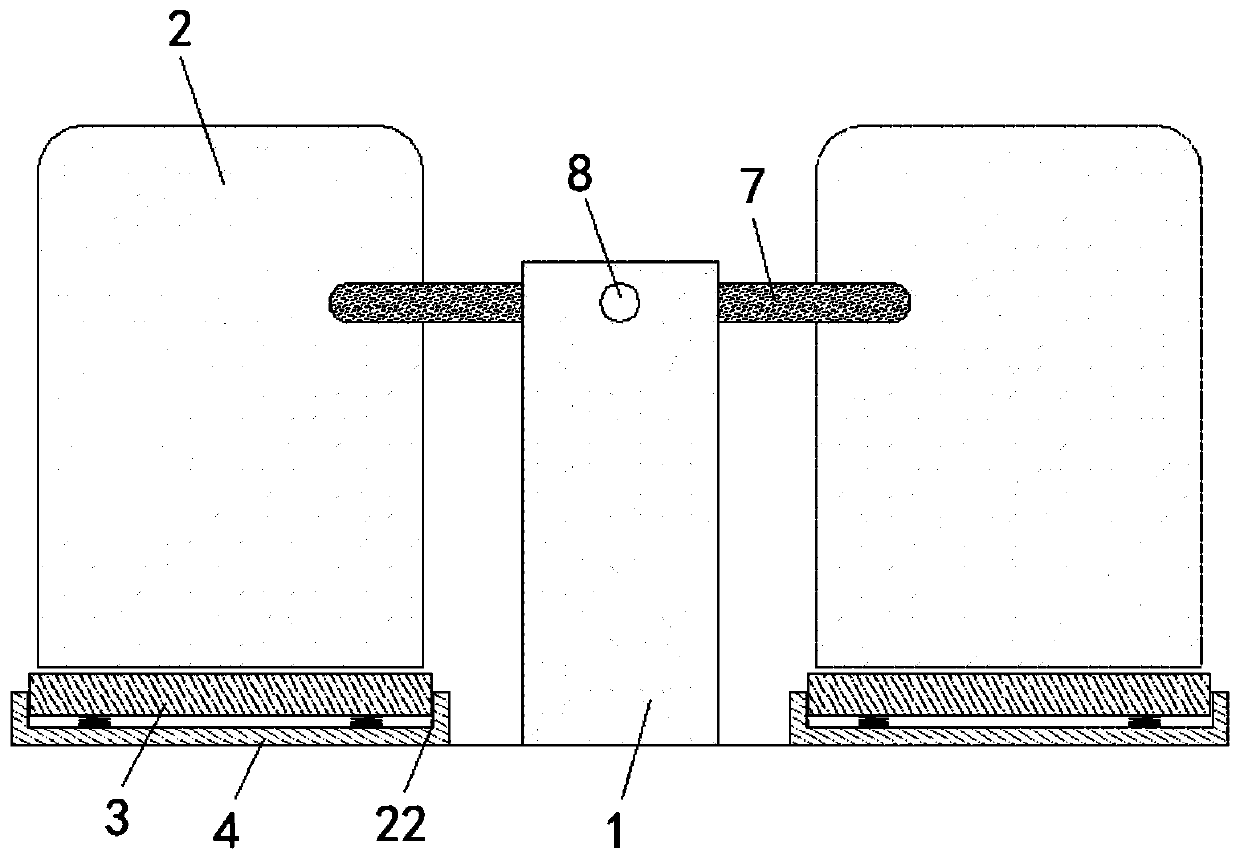

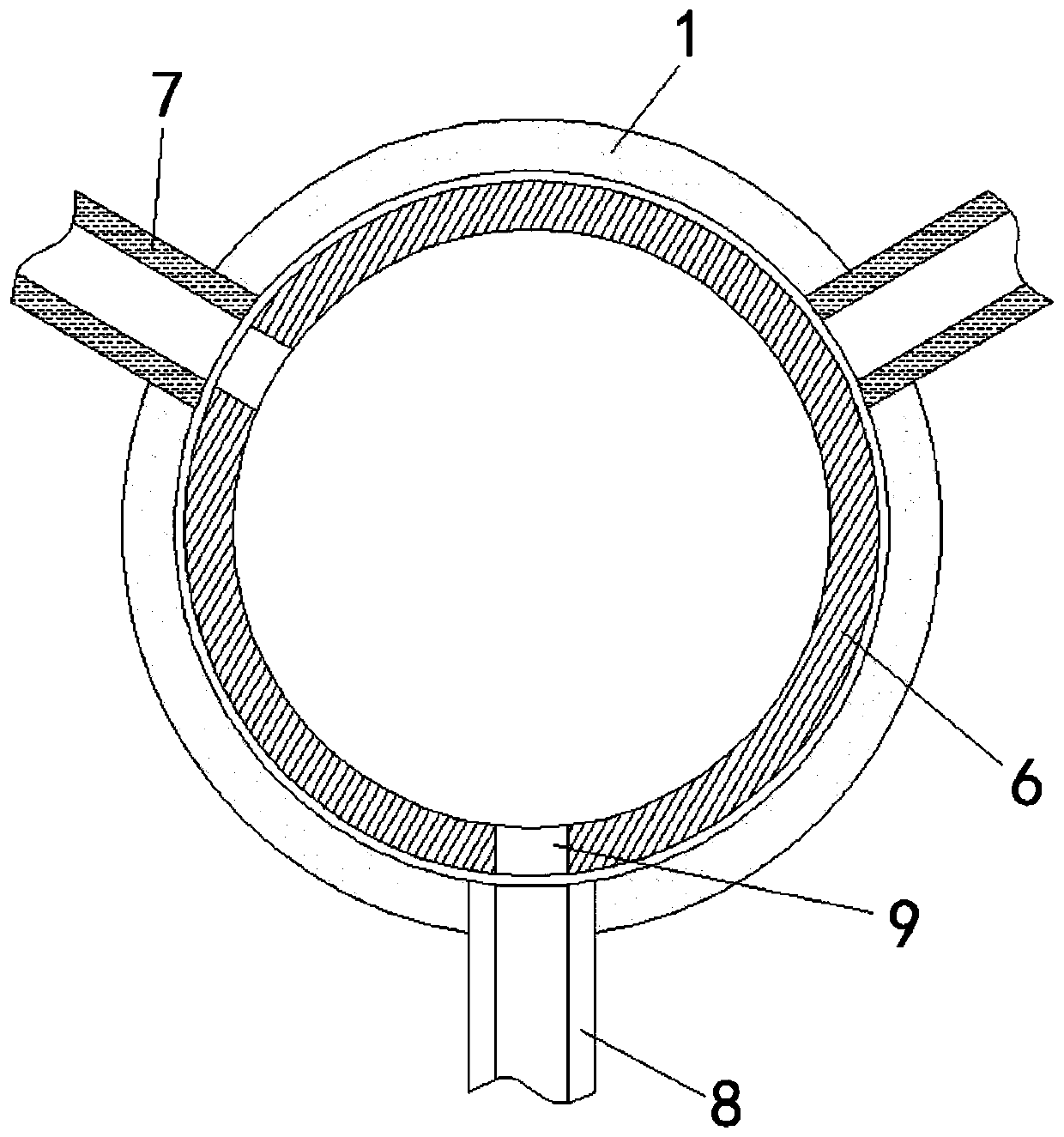

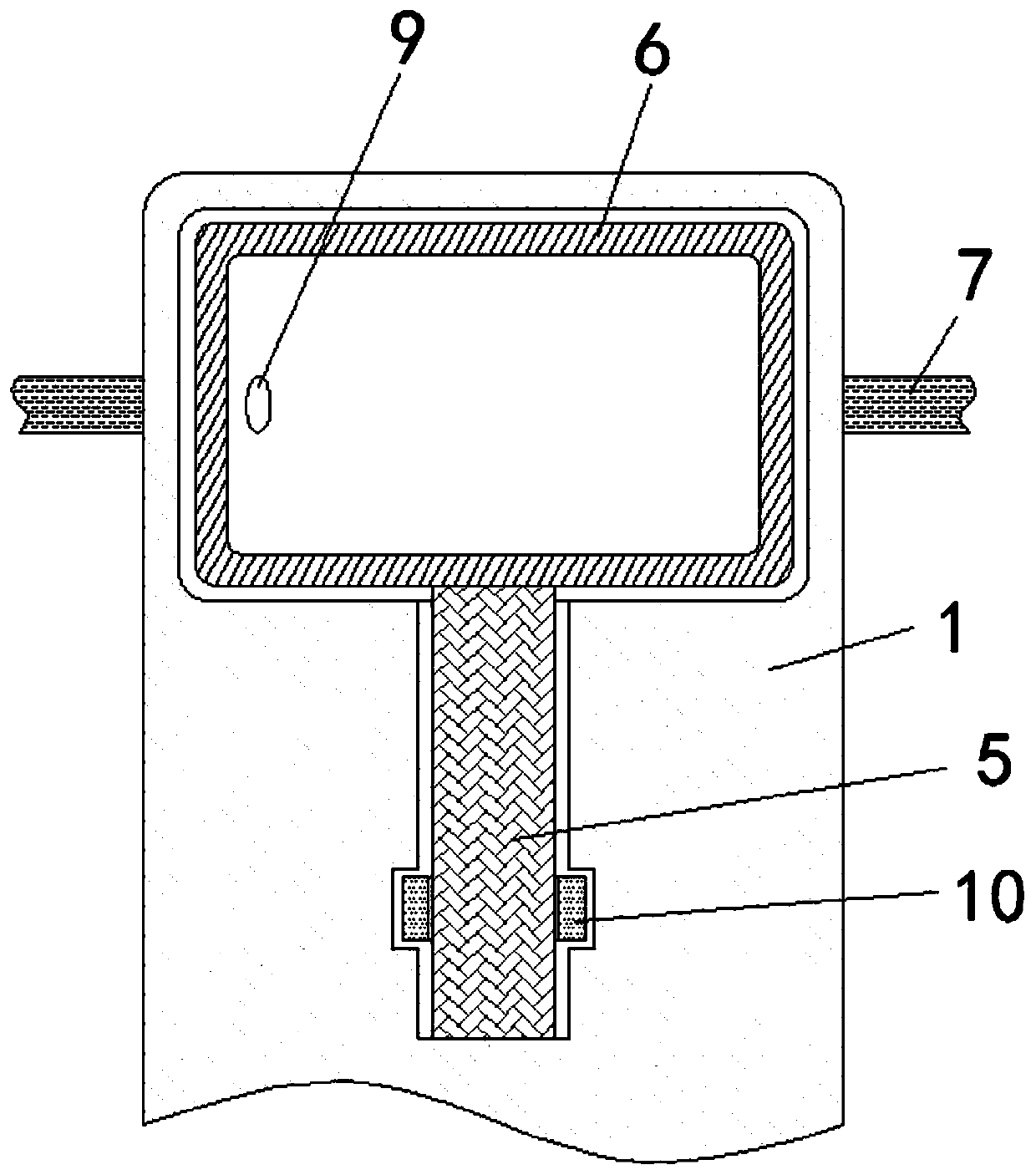

[0036] as attached figure 1 to attach Figure 10 Shown:

[0037] The present invention provides a waste refrigerant recovery adjustment device based on weight change, which includes a main base 1 and two recovery tanks 2, the recovery tank 2 is installed on the base 4 through a movable base 3, and the inside of the main base 1 is movably installed through a rotating shaft 5 There is an adjustment seat 6, an air outlet pipe 7 is connected between the main seat 1 and the recovery tank 2, an air intake pipe 8 is installed on the front of the main seat 1, and two air holes 9 respectively connected to the air pipe are opened on the side wall of the adjustment seat 6 The outer side of the rotating shaft 5 is fixedly sleeved with a gear one 10, the inside of the main seat 1 and the front side of the gear one 10 are movably connected with a driven plate 11, and the front side of the driven plate 11 is movably connected with a driving plate 12, and the driven plate 11 is movably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com