Seaside power plant circulating water pump double-frequency-conversion energy-saving control system and method

An energy-saving control system and circulating water pump technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve the problems of power consumption and energy waste, difficult measurement, and inconvenient use of circulating pumps, and reduce throttling losses , Reduce labor intensity, the effect of continuous instruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

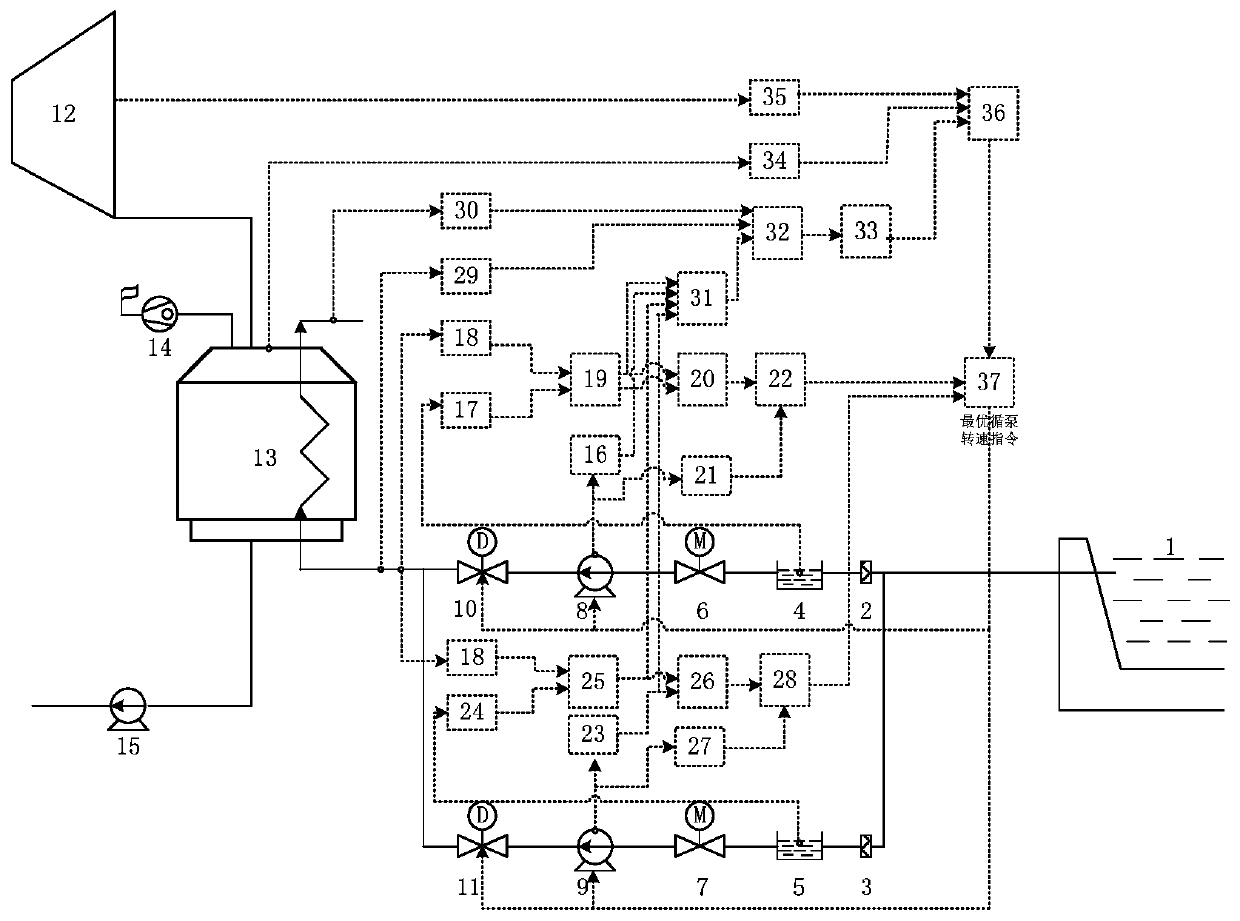

[0030] The cold end system of seaside power plant such as figure 1 As shown in the solid line block diagram, seawater 1 of the seaside power plant is filtered by the first forebay filter device 2 and the second forebay filter device 3 respectively, and then flows into the first circulating water forebay 4 and the second circulating water forebay 5, Keep the electric valve 6 at the inlet of the first circulating water pump and the electric valve 7 at the inlet of the second circulating water pump fully open. The circulating water inlet valve 11 of the second condenser is sent into the condenser 13 to cool the exhaust steam of the steam turbine 12, and then flows out of the condenser and returns to seawater. On the other side, the steam discharged from the steam turbine 12 enters the condenser 13, is cooled by circulating water and sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com