Luminous high-strength polyester industrial yarn and preparing method thereof

A high-strength polyester and industrial yarn technology, applied in the field of textiles, can solve the problems of poor friction resistance, disappearance of luminous properties of luminous fibers, and inability to wash with water, etc., and achieves the effects of long aging, excellent color fastness and uniform coloring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A luminous high-strength polyester industrial yarn, comprising the following raw materials in parts by mass: 14 pigments, 14 polymerizable dispersants, 0.8 anionic surfactants, 9 deionized water, 0.65 comonomers, and 0.014 initiators.

Embodiment 2

[0035] A luminous high-strength polyester industrial yarn, comprising the following raw materials in parts by mass: 15 pigments, 15 polymerizable dispersants, 1 anionic surfactant, 10 deionized water, 0.7 comonomers, and 0.015 initiators.

Embodiment 3

[0037] A luminous high-strength polyester industrial yarn, comprising the following raw materials in parts by mass: 16 pigments, 16 polymerizable dispersants, 1.2 anionic surfactants, 11 deionized water, 0.85 comonomers, and 0.016 initiators.

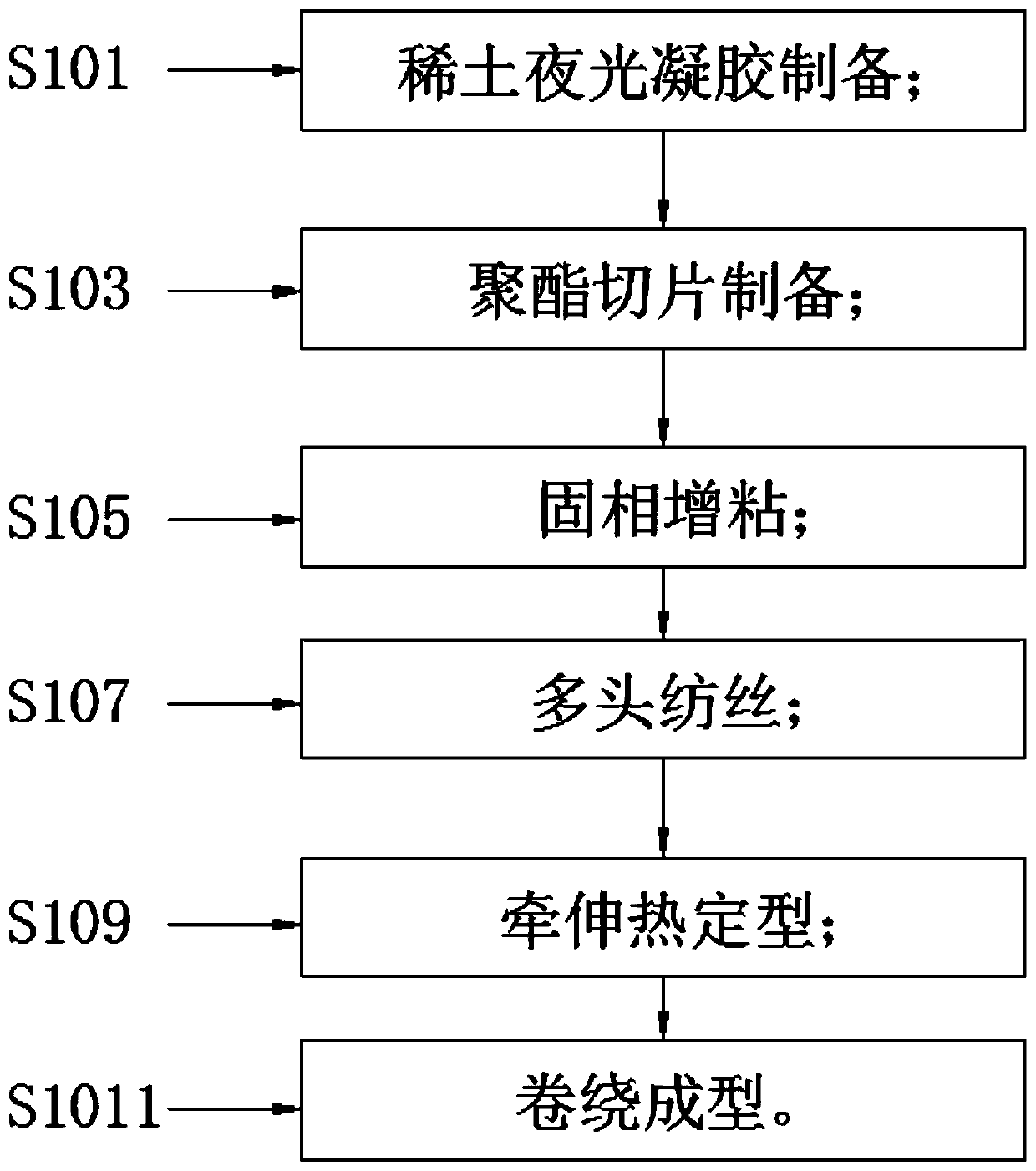

[0038] Such as figure 1 As shown, according to the embodiment of the present invention, a preparation method of luminous high-strength polyester industrial yarn is also provided.

[0039] Example 1, the preparation method of 16 spinning 500D luminous high-strength polyester industrial yarns,

[0040] Include the following steps:

[0041] Step S101: Preparation of rare earth luminous gel: Stir and disperse the pigment, dispersant, anionic surfactant and deionized water in a high-speed mixer, add the comonomer dropwise and continue stirring; after the dispersion is uniform, transfer the mixture to a nitrogen-filled In the reaction kettle, add the initiator dropwise after heating up, and react at a constant temperature; after the reaction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com