A method for extracting nickel and cobalt from the phosphoric acid leaching solution of laterite nickel ore

A laterite nickel ore and leachate technology, applied in the field of hydrometallurgy, can solve the problems of P507 organic reverse extraction, difficulty in separation of high-nickel and low-cobalt solution, high impurity content, etc., to improve extraction selectivity, facilitate industrial application, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

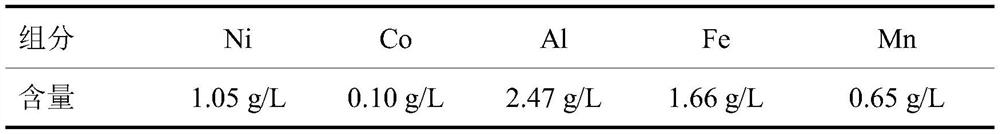

[0062] Step (1): Treat lateritic nickel ore by pre-roasting transformation-phosphoric acid atmospheric pressure leaching, pre-roasting temperature 400°C, roasting time 1h, phosphoric acid concentration 3mol / L, leaching temperature 90°C, leaching time 2h, leaching liquid-solid ratio 10: 1. After the leaching is completed, a section of leaching solution is obtained. The leaching rate of nickel is 98.43%, the leaching rate of cobalt is 89.69%, and the leaching rate of iron is 7.08%. The pH of the obtained leachate was 0.7, and the contents of main metal ions in the leachate were shown in Table 2.

[0063] Table 2 Concentration of metal element ions in leachate

[0064]

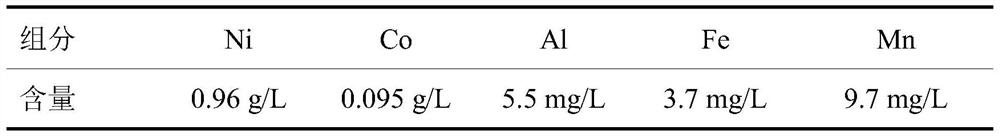

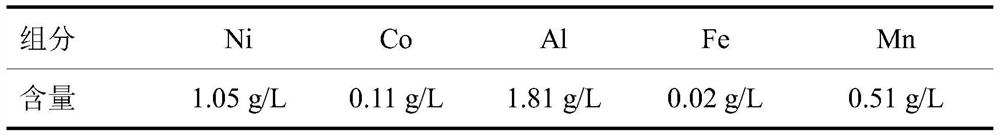

[0065] Step (2): Using ammonia water as an alkaline agent, adjust the pH of the leach solution obtained in step (1) to 3.0 to obtain the first impurity removal solution. At this time, the removal rates of aluminum, iron and manganese in the leach solution are 57.7% respectively , 91.2%, and 60.0%, and the los...

Embodiment 2

[0071] Compared with Example 1, the only difference is that in step (4), the extraction stages of P507 are three stages, and the cobalt extraction rates after three stages of extraction are 96.6% and 8.7%, respectively.

Embodiment 3

[0073] Compared with Example 1, the only difference is that in step (4), the extraction rates of cobalt and nickel after primary extraction are 54.2% and 2.5%, respectively. After the primary extraction through P507, the extraction rate of cobalt is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com