Silica gel chromatographic packing for separation of alkaline compound and preparation method of silica gel chromatographic packing

A technology for silica gel chromatography and compounds, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of unsatisfactory reproducibility and stability of chromatographic packing materials, and achieve good separation selectivity and preparation methods Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

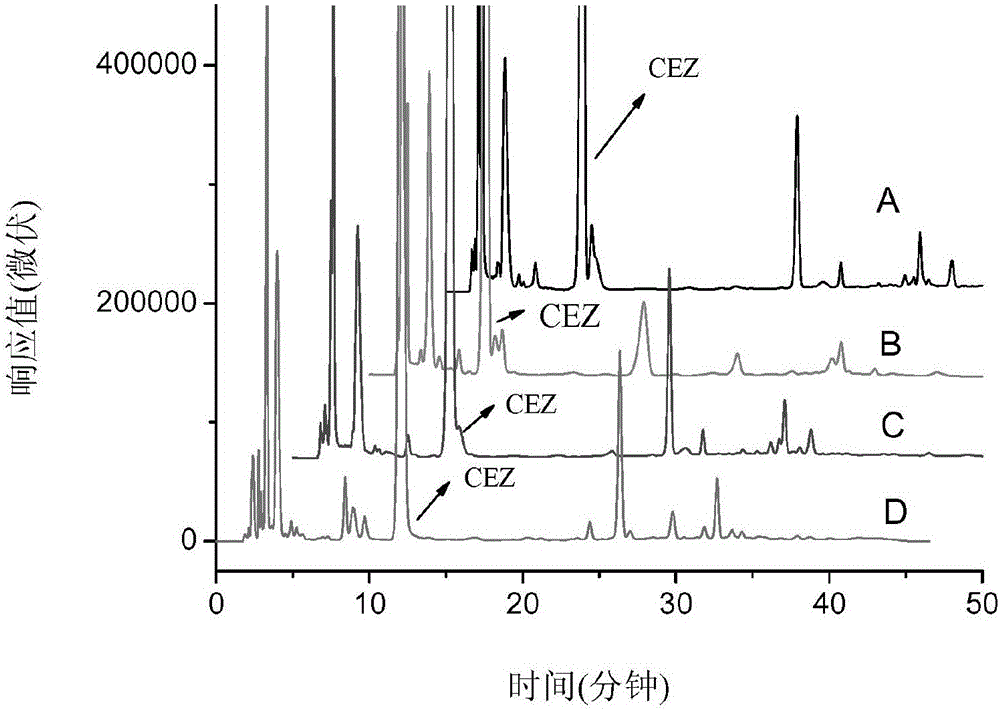

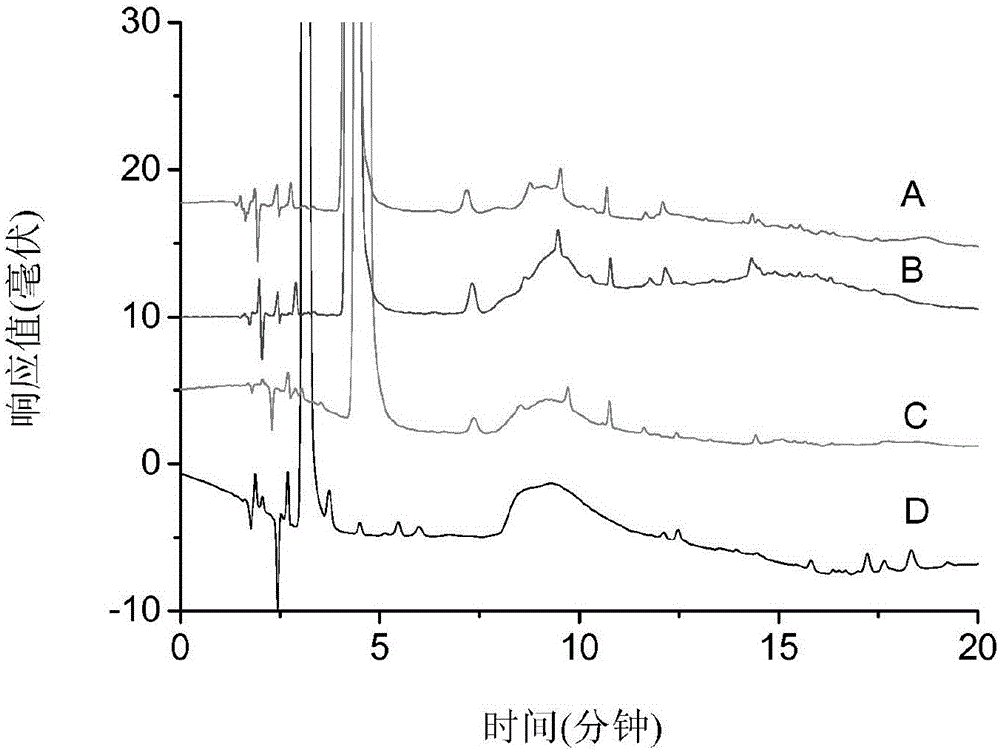

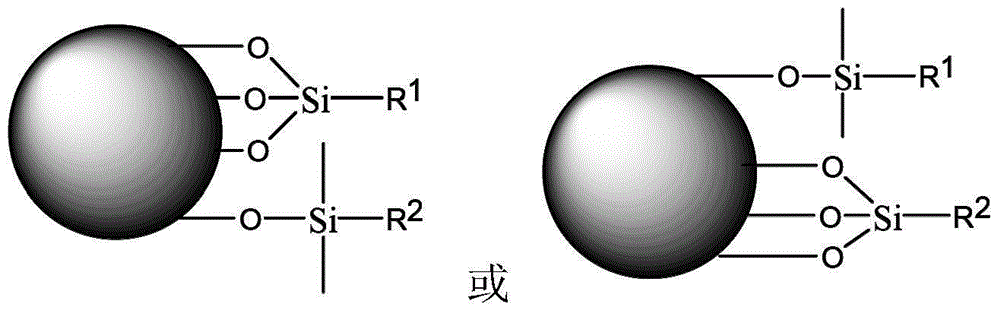

[0034] The invention provides a preparation method of silica gel chromatography packing for separating basic compounds, comprising: reacting silica gel with a mixture of non-polar silane coupling agent and polar silane coupling agent to prepare the silica gel chromatography packing; wherein, The non-polar silane coupling agent contains three hydrolyzable groups, and the polar silane coupling agent contains one hydrolyzable group; or the non-polar silane coupling agent contains one hydrolyzable group, so The polar silane coupling agent contains three hydrolyzable groups.

[0035] In one embodiment of the present invention, the chemical formula of the non-polar silane coupling agent is: X(Si)(CH 3 ) 2 R 1 , X is a hydrolyzable group, R 1 Selected from alkyl groups containing 1 to 20 carbon atoms, substituted alkyl groups containing phenyl groups containing 1 to 20 carbon atoms, substituted alkyl groups containing pentafluorophenyl groups containing 1 to 20 carbon atoms, or pe...

preparation example 1

[0065] (1) Add 100 g of silica gel (5 μm, purchased from DAISO, Japan) into a 2 L glass reaction vessel, add 1000 mL of distilled water, stir for 30 minutes, filter, and repeat this step twice. Then add 1000mL of hydrofluoric acid aqueous solution with a mass ratio of 0.08%, stir for 24 hours, wash with distilled water until neutral, finally add 1000mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0066] (2) Weigh 100g of activated silica gel (5μm, Specific surface area: 300m 2 / g), placed in a 2L glass material reaction vessel; 5g of ultrapure water was added to the reaction vessel, and stirred at 170 rpm for more than 30 minutes to obtain hydrated silica gel;

[0067](3) Add the hydrated silica gel prepared in step (2) to the glass material reaction vessel, and add 800mL of dry anhydrous toluene solvent, stir evenly at 170 rpm and add 24.45g of octadecyltrichlorosilane and 3.593g of a mixture of two silane reagents, chloroprop...

preparation example 2

[0071] (1) Add 100 g of silica gel (5 μm, purchased from DAISO, Japan) into a 2 L glass reaction vessel, add 1000 mL of distilled water, stir for 30 minutes, filter, and repeat this step twice. Then add 900mL of hydrofluoric acid aqueous solution with a mass ratio of 0.06%, stir for 24 hours, wash with distilled water until neutral, finally add 1000mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0072] (2) Weigh 100g of activated silica gel (5μm, Specific surface area: 300m 2 / g), placed in a 2L reaction vessel; 8g of ultrapure water was added to the glass reaction vessel, and stirred at 250 rpm for 30 minutes to obtain hydrated silica gel;

[0073] (3) Add the hydrated silica gel prepared in step (2) to the glass material reaction vessel, and add 800mL of dry anhydrous toluene solvent, stir at 170 rpm and add 26.07g of octadecyltrichlorosilane and 3. 111g of a mixture of 4-chlorobutyldimethylchlorosilane and two silane reagent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com