Oil slurry scale inhibitor of catalytic cracking unit and preparation method thereof

A technology for catalytic cracking unit and scale inhibitor, which is used in the petroleum industry, hydrocarbon oil treatment, and treatment equipment corrosion/fouling inhibition, etc., can solve the problems of lowering the temperature at the bottom of the tower, lowering the heat exchange effect, and increasing the yield of oil slurry, etc. To achieve the effect of enhanced anti-corrosion performance, good dispersion, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

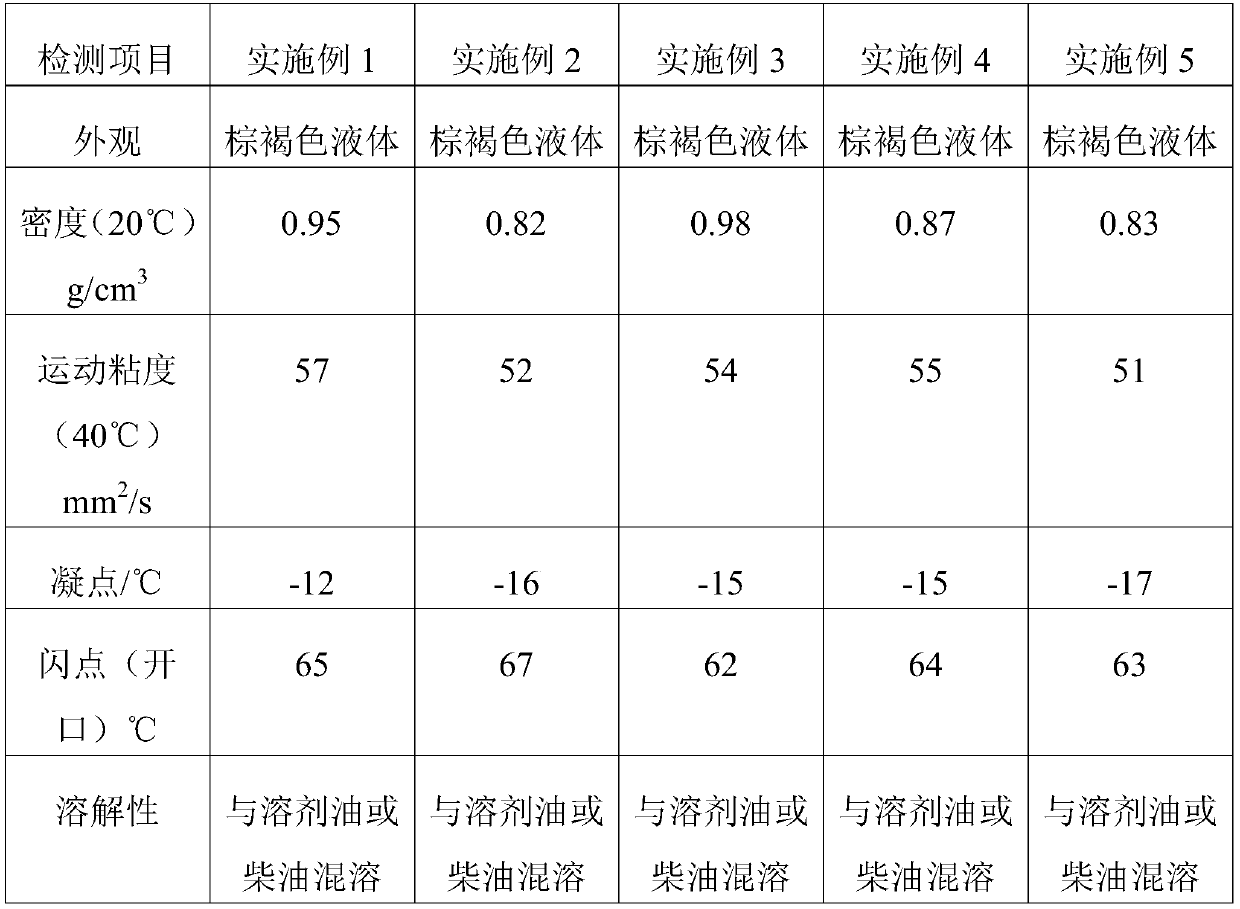

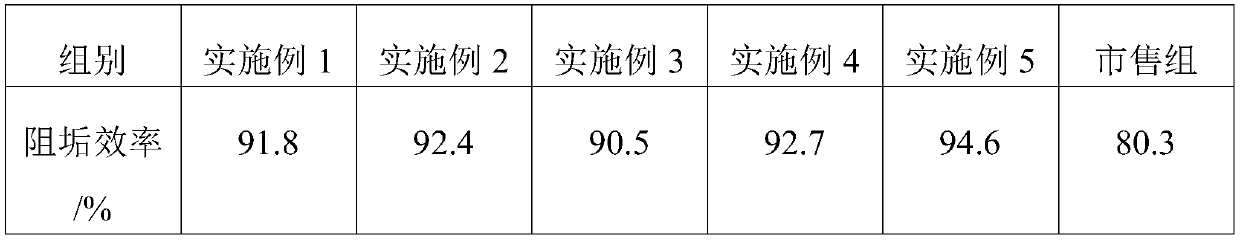

Examples

Embodiment 1

[0027] This embodiment provides a kind of preparation method of the oil slurry antiscalant of catalytic cracking unit:

[0028] 5kg N-cyclohexylthiophthalamide, 5kg 2-tert-butyl hydroquinone, 25kg sodium dodecyl sulfate, 5kg oleylamine ethyl imidazoline, 15kg xylene and 45kg 200# solvent The oil is stirred for 50 minutes under the condition of 40r / min, and the oil slurry scale inhibitor of the catalytic cracking unit is obtained.

Embodiment 2

[0030] This embodiment provides a kind of preparation method of the oil slurry antiscalant of catalytic cracking unit:

[0031] Stir 10kg of benzoic acid, 10kg of methyl hydroquinone, 30kg of polyacrylamide, 10kg of trans oleylamine ethyl imidazoline, 25kg of methanol and 15kg of 200# solvent oil under the condition of 50r / min for 60min to obtain catalytic cracking Slurry antiscalant for equipment.

Embodiment 3

[0033] This embodiment provides a kind of preparation method of the oil slurry antiscalant of catalytic cracking unit:

[0034] The composition of 7.5kg N-nitroso diphenylamine, 7.5kg 2-tert-butyl hydroquinone and methyl hydroquinone, the composition of 27.5kg sodium lauryl sulfate and polyacrylamide, 7.5kg cis The composition of oleic acid amine ethyl imidazoline, 20kg of xylene and methanol, and 30kg of 200# solvent oil were stirred for 55min under the condition of 45r / min to obtain the oil slurry scale inhibitor of the catalytic cracking unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com