Low-oxygen liquid SiHfBCN ceramic precursor, preparation method and SiHfBCN ceramic

A ceramic precursor and precursor technology, applied in the field of inorganic materials, can solve the problems of poor rheological properties, decreased performance of composite materials, low ceramic yield, etc., achieve excellent high temperature resistance and oxidation resistance, improve processing performance, flow Variable performance controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041]The preparation method of the above-mentioned low-oxygen liquid SiHfBCN ceramic precursor specifically includes the following steps:

[0042] Step 1: replacing the air in the Schlenk reactor with an inert gas, specifically, firstly evacuating the reactor and then filling the inert gas, repeating 3 to 5 times. Add a certain amount of organic solvent, put the unsaturated group-containing liquid SiBCN precursor and the unsaturated group-containing hafnium precursor into the reactor in a certain proportion at 20 ~ 30 ℃, and add a certain amount of free radical initiator , a homogeneous solution is obtained after fully stirring.

[0043] Step 2: heating the obtained homogeneous solution to initiate radical polymerization between unsaturated groups in the system to obtain SiHfBCN precursor, the reaction temperature is 60-180°C, and the reaction time is 0.5-2h.

[0044] Step 3: After the reaction is completed, the temperature of the system is lowered to below 30 °C, and then t...

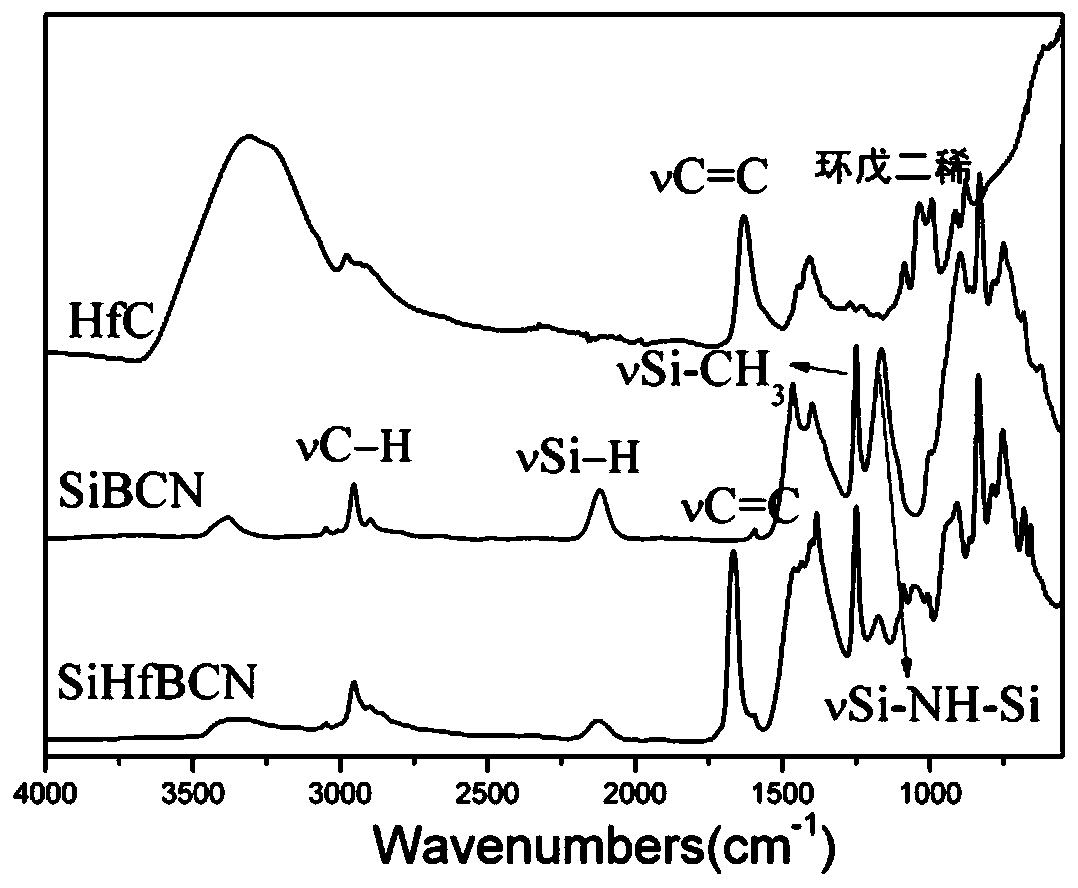

Embodiment 1

[0054] 1) The air in the Schlenk reactor is replaced with an inert gas, specifically, the reactor is first evacuated and then filled with an inert gas, repeating 3 to 5 times. Add solvent N,N-dimethylformamide 40ml, at 25 ℃ add SiBCN precursor (PSNB) 10g, dicocyl diallyl hafnium 10g, dicumyl peroxide 0.1g, stir well and get brown color Homogeneous solution.

[0055] 2) The homogeneous solution obtained above was heated to 140°C and kept for 0.5h.

[0056] 3) After the reaction is completed, the system temperature is lowered to below 30°C, and then the vacuum pump is turned on, and the solvent is removed by distillation under reduced pressure. The distillation temperature is 60°C, and the vacuum degree is -0.09 to -0.1Mpa, until no solvent escapes in the system. The vacuum was stopped, and the temperature was lowered, and finally a brown liquid SiHfBCN precursor was obtained.

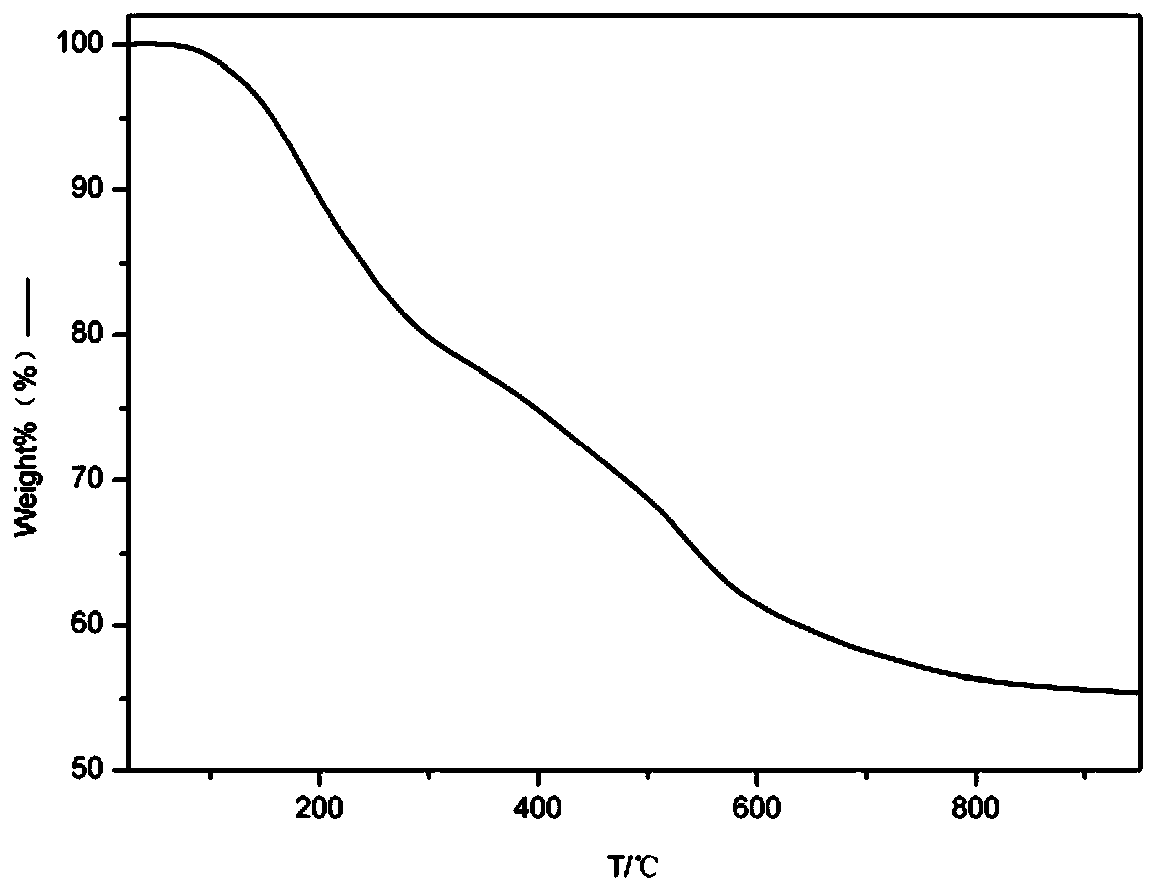

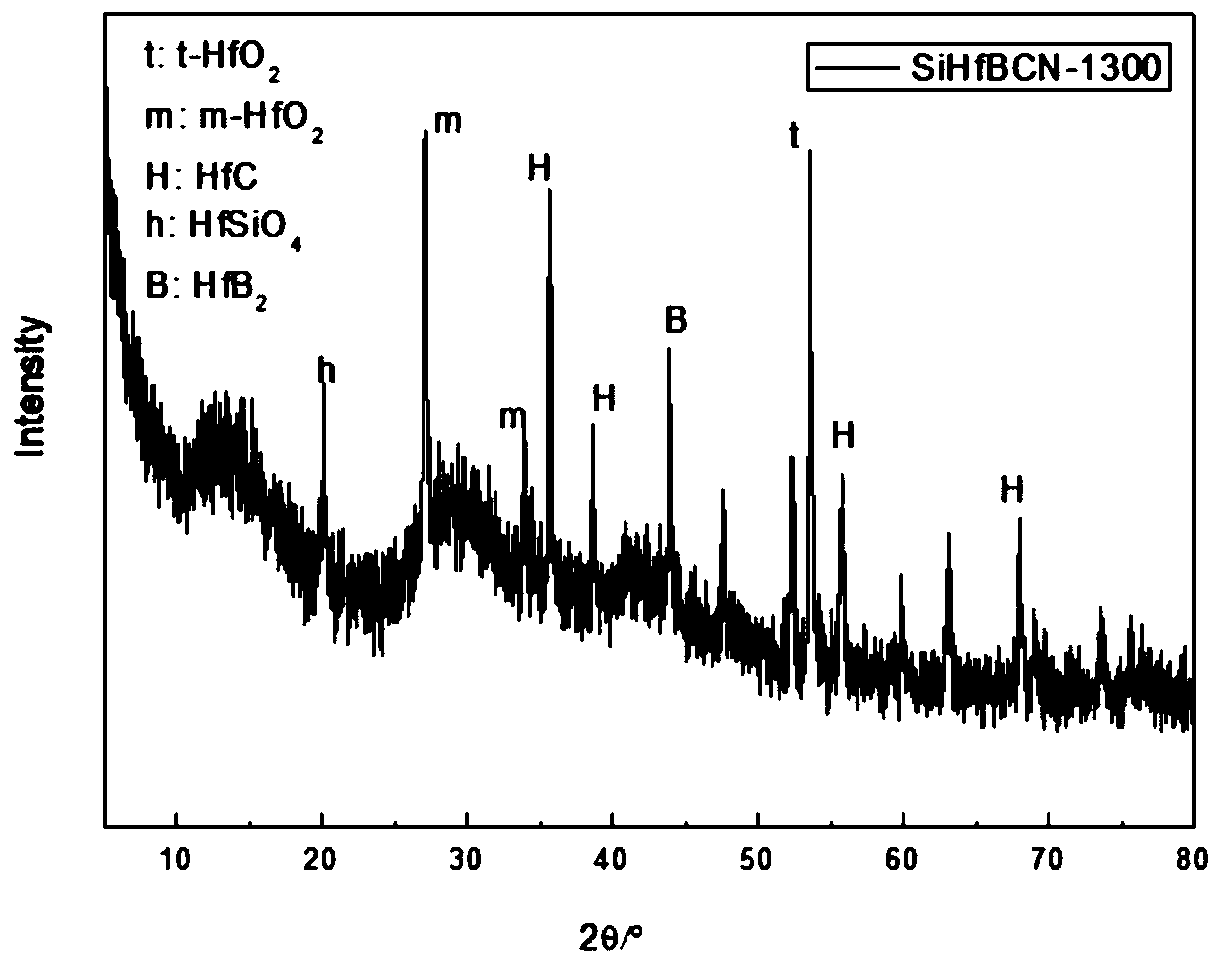

[0057] 4) The SiHfBCN precursor is placed in a tube furnace, and the SiHfBCN ceramic can be obtaine...

Embodiment 2

[0061] 1) The air in the Schlenk reactor is replaced with an inert gas, specifically, the reactor is first evacuated and then filled with an inert gas, repeating 3 to 5 times. Add solvent N,N-dimethylformamide 30ml, add SiBCN precursor (PSNB) 10g, dimethyldiallyl hafnium 5g, dicumyl peroxide 0.075g at 25°C, stir well and get brown color Homogeneous solution.

[0062] 2) The homogeneous solution obtained above was heated to 140°C and kept for 0.5h.

[0063] 3) After the reaction is completed, the system temperature is lowered to below 30°C, and then the vacuum pump is turned on, and the solvent is removed by distillation under reduced pressure. The distillation temperature is 60°C, and the vacuum degree is -0.09 to -0.1Mpa, until no solvent escapes in the system. The vacuum was stopped, and the temperature was lowered, and finally a brown liquid SiHfBCN precursor was obtained.

[0064] 4) The SiHfBCN precursor is placed in a tube furnace, and the SiHfBCN ceramic can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com