A kind of cement slurry with controllable rheology and its preparation method

A technology of rheology and cement, applied in the field of cement, can solve problems such as difficult to obtain raw materials and methods, too long initial setting time, and uncontrollable rheological properties of cement slurry, so as to achieve short initial setting-final setting time interval and promote cement Controllable effect of hydration process and flow denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A cement slurry with controllable rheology and a preparation method thereof. The cement slurry with controllable rheology is made of 30-35wt% calcium aluminate cement and 65-70wt% α-alumina micropowder as raw materials, and mixed evenly; then adding 1-15wt% silicon The sol and 35-40wt% water were stirred for 3-8 minutes to obtain cement slurry with controllable rheology.

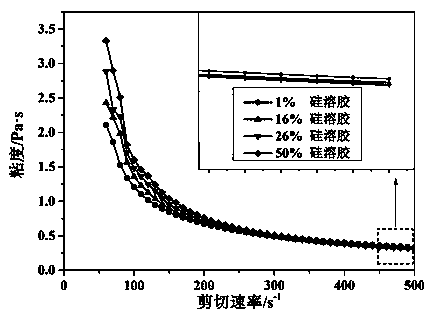

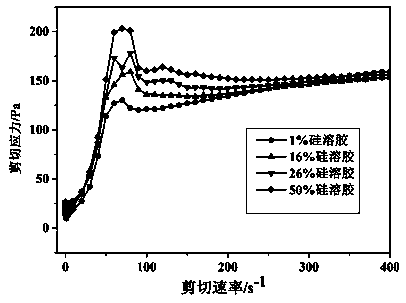

[0021] A cement slurry with controllable rheology prepared in this example is poured into the cylinder of the rheometer, and the rheological shear rate is: 0.1 100s 1 20s 10 100s 500 30s 500 120s 1s -1 ; The obtained shear rate-viscosity curve is as figure 1 Contain 1wt% silica sol curve to show in, shear rate-shear stress curve is as shown in figure 2 It is shown in the curve containing 1wt% silica sol.

[0022] The cement slurry with controllable rheology prepared in this example is tested: the initial setting time is 140-155 minutes; the final setting time is 185-195 minutes.

Embodiment 2

[0024] A cement slurry with controllable rheology and a preparation method thereof. The cement slurry with controllable rheology is made of 34-40wt% calcium aluminate cement and 60-66wt% α-alumina micropowder as raw materials, and mixed evenly; then adding 14-25wt% silicon The sol and 35-40wt% water were stirred for 3-8 minutes to obtain cement slurry with controllable rheology.

[0025] A cement slurry with controllable rheology prepared in this example is poured into the cylinder of the rheometer, and the rheological shear rate is: 0.1 100s 1 20s 10 100s 500 30s 500 120s 1s -1 ; The obtained shear rate-viscosity curve is as figure 1 Contain 16wt% silica sol curve to show in, shear rate-shear stress curve is as shown in figure 2 shown.

[0026] The cement slurry with controllable rheology prepared in this example is tested: the initial setting time is 130-145 minutes, and the final setting time is 168-190 minutes.

Embodiment 3

[0028] A cement slurry with controllable rheology and a preparation method thereof. The cement slurry with controllable rheology is made of 39-45wt% calcium aluminate cement and 55-61wt% α-alumina micropowder as raw materials, and mixed evenly; then adding 24-35wt% silicon The sol and 35-40wt% water were stirred for 3-8 minutes to obtain cement slurry with controllable rheology.

[0029] A cement slurry with controllable rheology prepared in this example is poured into the cylinder of the rheometer, and the rheological shear rate is: 0.1 100s 1 20s 10 100s 500 30s 500 120s 1s -1 ; The obtained shear rate-viscosity curve is as follows figure 1 Containing 26wt% silica sol curve in the middle, shear rate-shear stress curve is as shown in figure 2 shown.

[0030] The cement slurry with controllable rheology prepared in this example is tested: the initial setting time is 120-135 minutes, and the final setting time is 150-170 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com