Inorganic green body reinforcing agent based on silicate system

A green body reinforcing agent and silicate technology, applied in the field of ceramic industry, can solve the problems of insoluble in water, pinholes, poor fluidity of mud, etc., and achieve the effects of good dispersibility, good plasticity and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

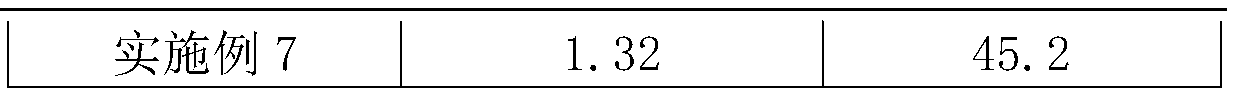

Examples

preparation example Construction

[0046] The preparation process of lithium magnesium silicate sodium salt is as follows: sodium, magnesium and lithium salts are mixed with sodium silicate at a certain speed and temperature to produce amorphous precipitates, and then some crystals are formed by high temperature treatment, and the obtained products are filtered. Washing, drying and milling give a fine white powder.

[0047] Further, the mass ratio of sodium silicate to sodium fluorosilicate is 4-8:1. The mass ratio of sodium silicate to magnesium lithium silicate is 4-8:1.

[0048] Preferably, the inorganic body strengthening agent based on silicate system includes the following components in parts by weight:

[0049] 1-2 parts of inorganic nano-oxide powder;

[0050] 1-3 parts of sodium sulfate;

[0051] 1-3 parts of aluminum sulfate;

[0052] 1-3 parts of sodium pyrophosphate;

[0053] 5-10 parts of sodium silicate;

[0054] 0.1-1 part of sodium fluorosilicate;

[0055] 0.1-1 part of lithium magnesium ...

Embodiment 1

[0060] Take 1 part of inorganic nano-oxide powder, 0.1 part of lithium magnesium silicate and mix with water, stir evenly to form a dispersion, then add 1 part of sodium sulfate, 1 part of aluminum sulfate, 1 part of sodium pyrophosphate, 5 1 part of sodium silicate and 0.1 part of sodium fluorosilicate, heated to 100°C, stirred at constant temperature, and then spray-dried to obtain the inorganic body reinforcing agent.

[0061] Among them, the inorganic nano-oxide powder is composed of fumed titanium dioxide, fumed alumina, and hydrophilic fumed silica at a mass ratio of 1:1:2.

Embodiment 2

[0063] The difference between Example 2 and Example 1 is that the strengthening agent includes the following components by weight: 2 parts of inorganic nano oxide powder, 3 parts of sodium sulfate, 3 parts of aluminum sulfate, 3 parts of sodium pyrophosphate, 10 parts of silicic acid Sodium, 0.5 parts sodium fluorosilicate, 0.5 parts lithium magnesium silicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com