Method for preparing high-density silicon nitride ceramic through multi-factor optimization and prepared silicon nitride ceramic

A technology of silicon nitride ceramics and density, which is applied in the field of silicon nitride ceramics, can solve problems such as difficulty in obtaining high density, achieve high strength, excellent mechanical properties, and reduce pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

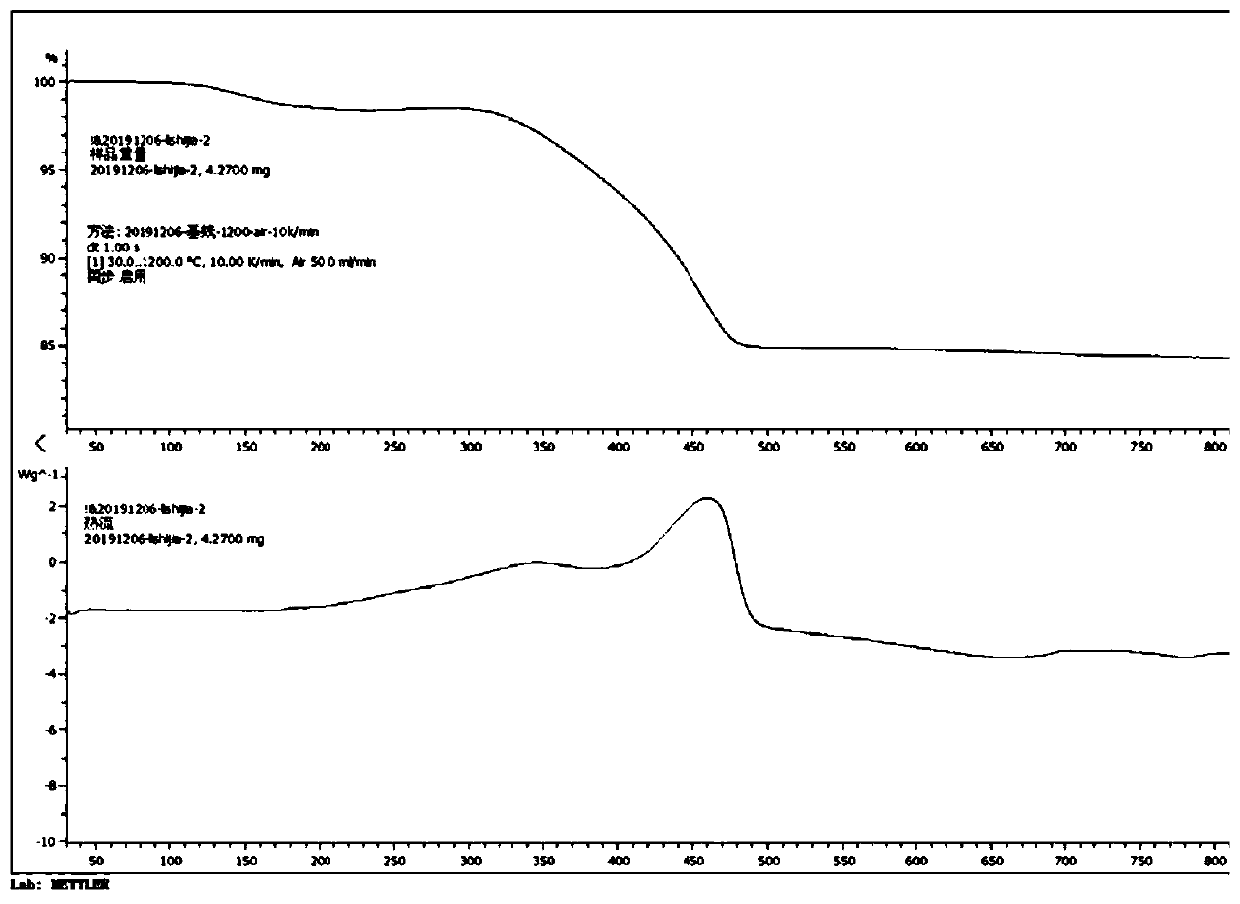

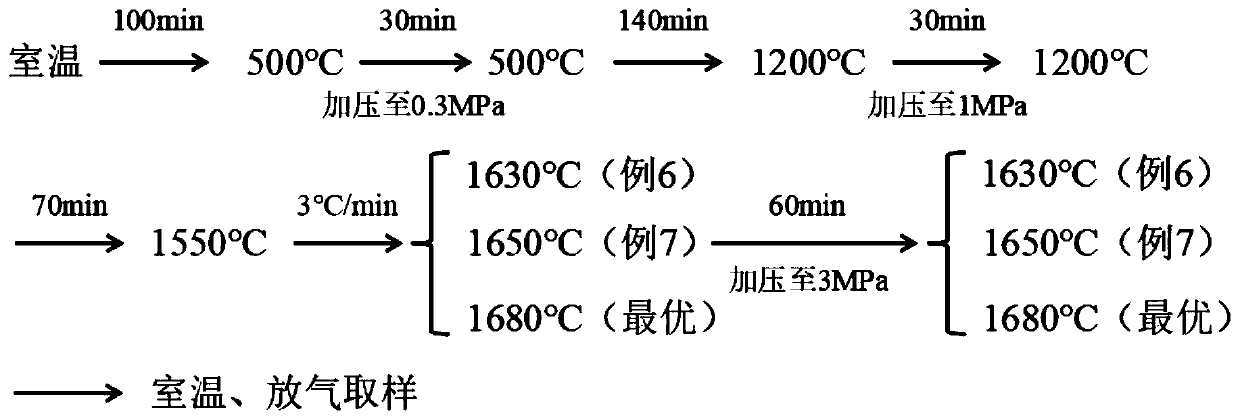

Method used

Image

Examples

Embodiment 1

[0054] Step 1, the mixing of the mixture

[0055] (1) Weigh the composite powder. In terms of mass percentage, the raw material of the composite powder includes 94% silicon nitride powder and 6% sintering aid. The sintering aid is a mixture of lutetium oxide, lanthanum oxide and aluminum oxide, and the mass ratio of lutetium oxide, lanthanum oxide and aluminum oxide is 2:1:1.

[0056] (2) Wet grinding and mixing. Using silicon nitride grinding balls as the ball milling medium, mix the weighed composite powder and alcohol into a planetary ball mill with a ball-to-battery ratio of 2:1, a rotating speed of 240r / min, and a milling time of 24h; before the ball milling, The dispersant sodium polyacrylate and the binder 2130 phenolic resin are added, and the dispersant and binder are respectively 2% and 2% of the total mass of the composite powder in terms of mass percentage.

[0057] Step 2, spray granulation and compaction of composite powder

[0058] (1) Spray and granulate the mixture...

Embodiment 2

[0063] Step 1, the mixing of the mixture

[0064] (1) Weigh the composite powder. In terms of mass percentage, the raw material of the composite powder includes 94% silicon nitride powder and 6% sintering aid. The sintering aid is a mixture of lutetium oxide, lanthanum oxide and aluminum oxide, and the mass ratio of lutetium oxide, lanthanum oxide and aluminum oxide is 2:1:1.

[0065] (2) Wet grinding and mixing. Using silicon nitride grinding balls as the ball milling medium, mix the weighed composite powder and alcohol into a planetary ball mill. The ball-to-battery ratio is 2:1, the speed is 240r / min, and the milling time is 24h; before the ball milling starts, The dispersant sodium polyacrylate and the binder 2130 phenolic resin are added, and the dispersant and binder are respectively 2% and 3% of the total mass of the composite powder in terms of mass percentage.

[0066] Step 2, spray granulation and compaction of composite powder

[0067] (1) Spray and granulate the mixture...

Embodiment 3

[0072] Step 1, the mixing of the mixture

[0073] (1) Weigh the composite powder. In terms of mass percentage, the raw material of the composite powder includes 94% silicon nitride powder and 6% sintering aid. The sintering aid is a mixture of lutetium oxide, lanthanum oxide and aluminum oxide, and the mass ratio of lutetium oxide, lanthanum oxide and aluminum oxide is 2:1:1.

[0074] (2) Wet grinding and mixing. Using silicon nitride grinding balls as the ball milling medium, mix the weighed composite powder and alcohol into a planetary ball mill. The ball-to-battery ratio is 2:1, the speed is 240r / min, and the milling time is 24h; before the ball milling starts, The dispersant sodium polyacrylate and the binder 2130 phenolic resin are added. In terms of mass percentage, the dispersant and binder are added in 2% and 5% of the total mass of the composite powder, respectively.

[0075] Step 2, spray granulation and compaction of composite powder

[0076] (1) Spray and granulate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com