Operation trolley for installing steel bars of dam panels and using method

A workbench and panel technology, applied in the direction of hoisting device, hoisting device, etc., can solve the problems of difficult breakthrough in construction progress, inability to take protective measures, large manpower, material resources, etc., to reduce unsafe hidden dangers and quality control. Guaranteed and safe construction with guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

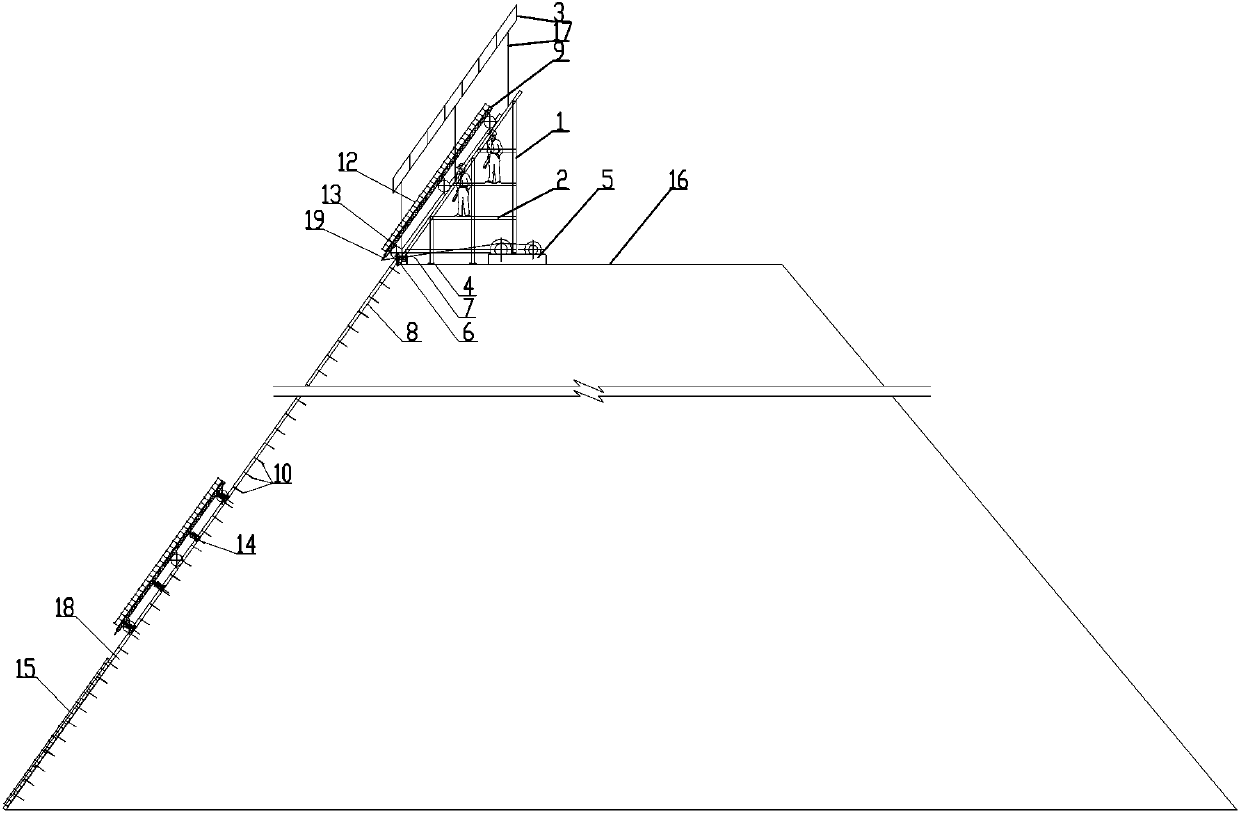

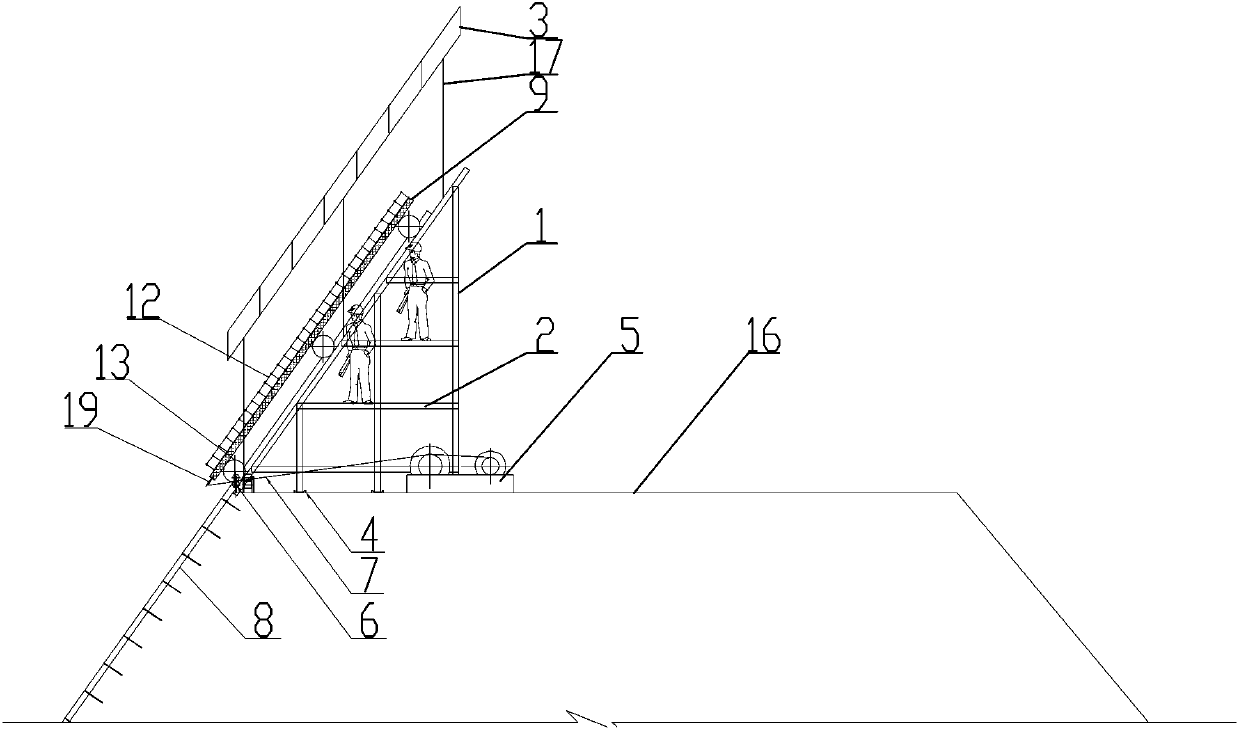

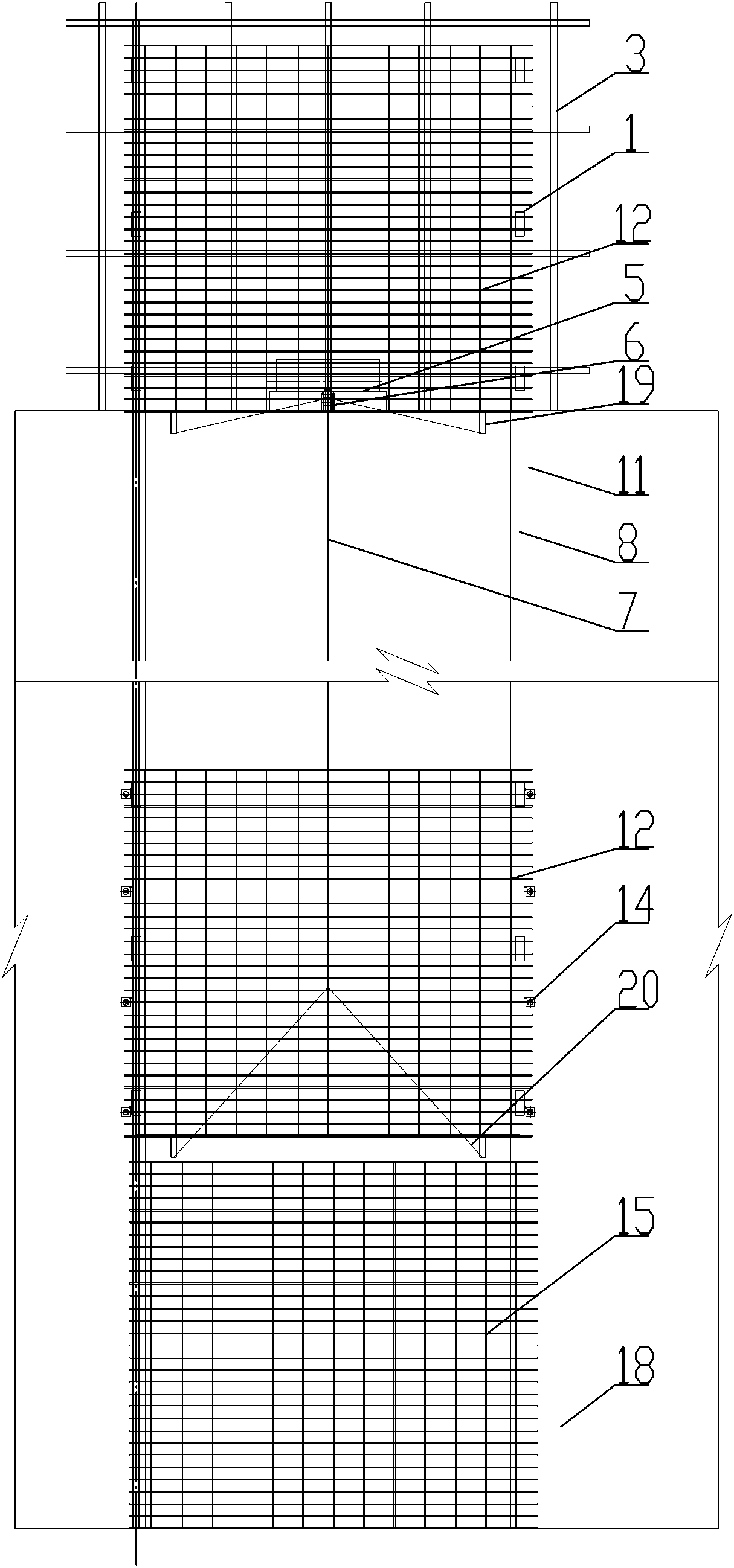

[0039] see Figure 1-4 , a working trolley installed with dam face reinforcement, which includes a working platform 1, on which a transport bracket 9 is supported by slide rails, and a bracket is installed at the bottom of the transport bracket 9 Roller 13, on the upstream slope dam 18 of steel cage to be installed, the sliding track 8 that is arranged in parallel is installed, and described sliding track 8 is docked with the slide rail on the workbench 1, and carries out rolling support to transport bracket 9 To realize the movement; the transport bracket 9 is connected with the winch power device for pulling it to move. By adopting the above-mentioned operating trolley, the main process in the installation process of steel bars, the binding work of steel bars, is bound into steel bar cages in sections on the special work platform 1 at the top of the dam, and the steel bar cages are lifted by the special transport trolley using the hoisting power device. Slide along the trac...

Embodiment 2

[0049] The method for using the dam panel reinforcing bar installation trolley comprises the following steps:

[0050] Step1, manufacture of work trolley: use scaffolding steel pipe or section steel to directly assemble and weld at the appropriate position of dam crest 16, and arrange suitable graded work platform 2 according to the requirements of steel bar binding, set up sunshade and rain shed 3 and install ventilation and cooling facilities according to requirements;

[0051] Step2, installation of sliding track 8: first measure and mark the installation position of the track on the mortar strip concrete 11, firmly fix the sliding track 8 on the installation position of the dam slope with the sliding track anchor bar 10, and adopt socket connection between the sections, And ensure that the sliding rails 8 on both sides are parallel and the joints are smooth;

[0052] Step3, production of transport bracket 9: welded with section steel on the workbench 1, and install sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com