Double-layer co-extruded aluminum-wood plastic profile and preparation method thereof

A wood-plastic profile, double-layer co-extrusion technology, applied to wood layered products, chemical instruments and methods, coatings, etc., can solve the problems of poor nail holding power and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

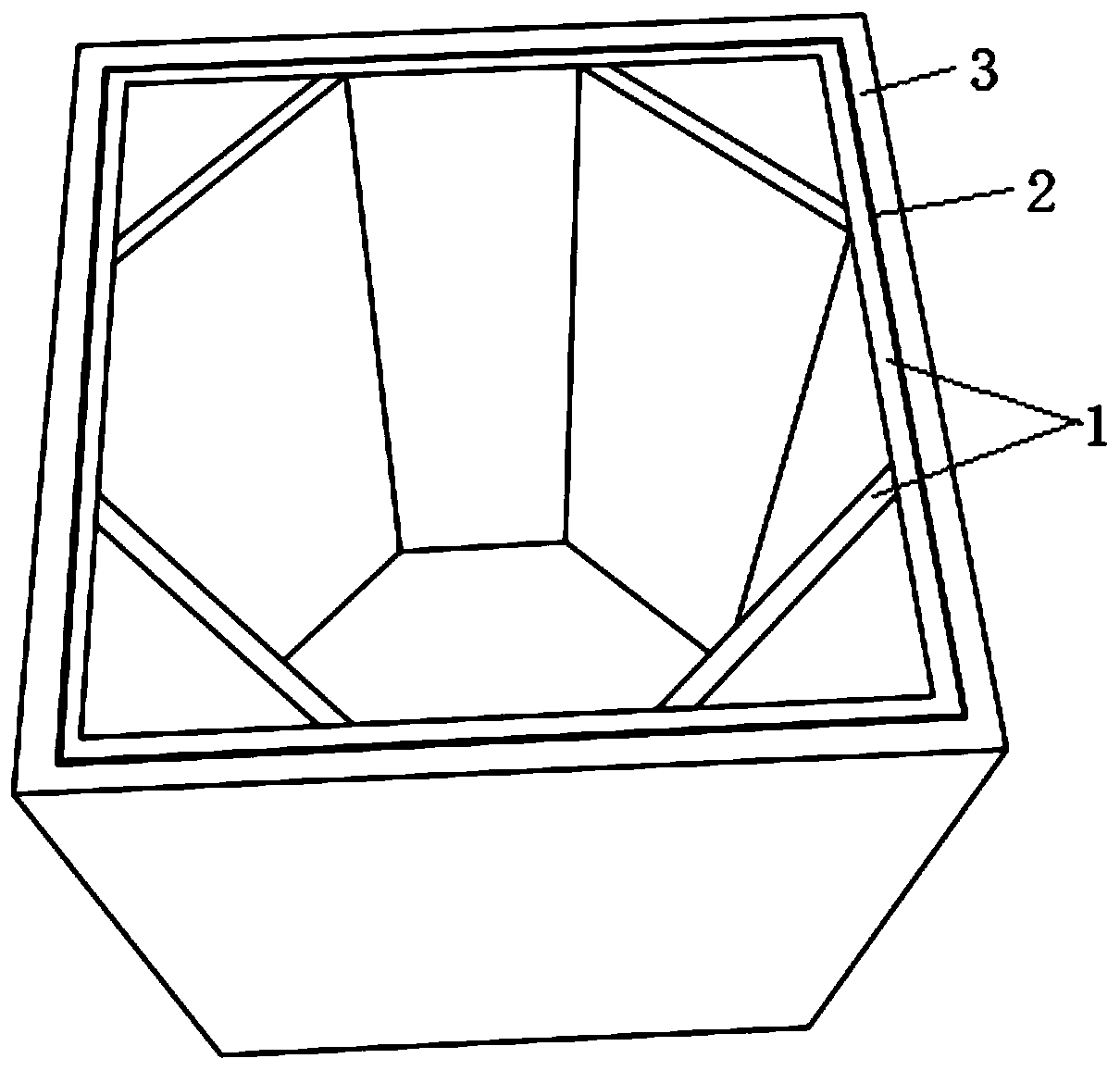

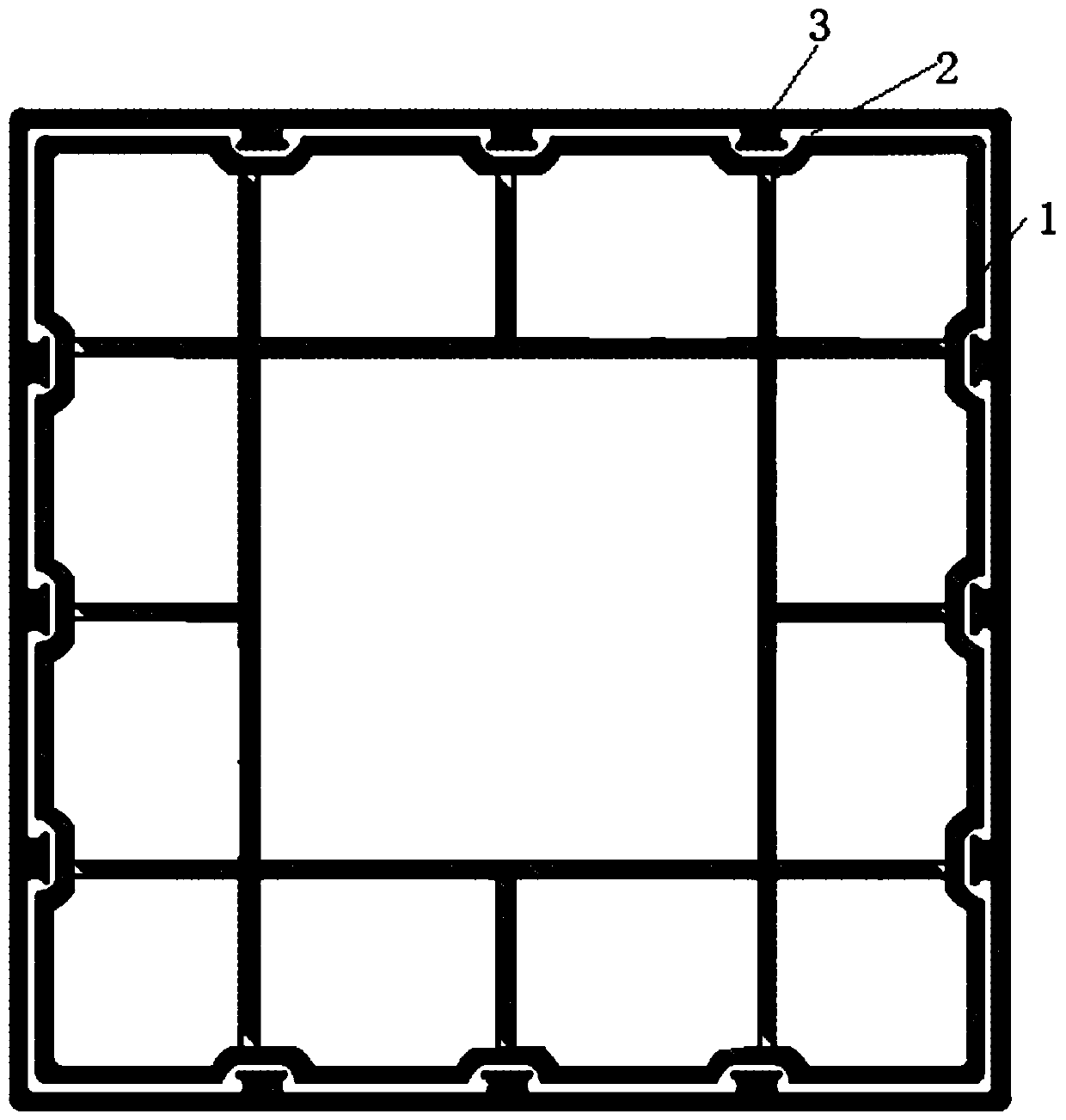

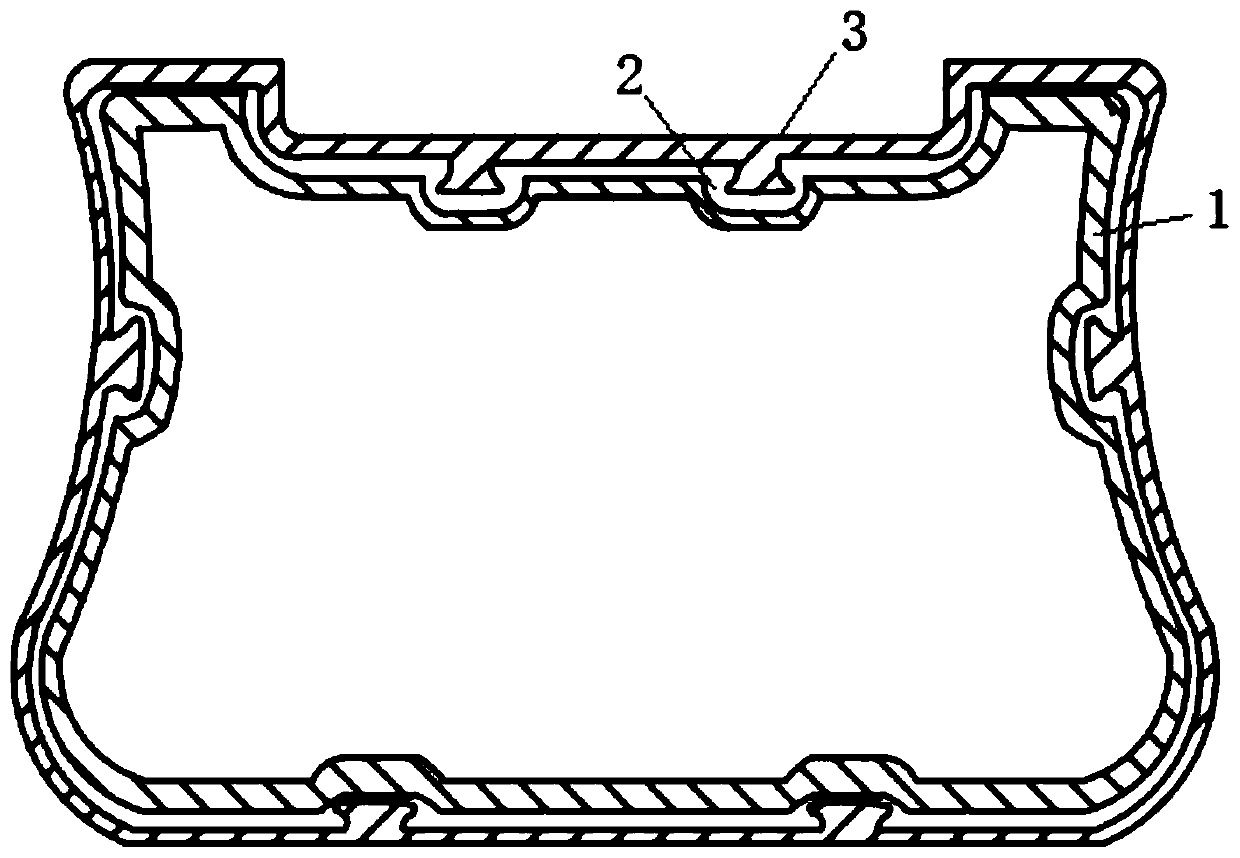

[0077] Such as Figure 1-3 As shown, the embodiment of the present invention provides a double-layer co-extruded aluminum-wood-plastic profile, including:

[0078] Aluminum substrate 1; the aluminum substrate can be a tubular aluminum substrate or a plate aluminum substrate or be in other shapes. When a tubular aluminum substrate is used, the ethylene-1-butene copolymer layer 2 can be coated with an existing aluminum tube laminating machine.

[0079] Ethylene-1-butene copolymer layer 2, coated (such as by bonding) on the aluminum substrate 1;

[0080] The wood-plastic material 3 is co-extruded on the ethylene-1-butene copolymer layer 2 . The ethylene-1-butene copolymer layer 2 can use the existing ethylene-1-butene copolymer material or the material in Example 2 below.

[0081] Such as Figure 6 As shown, the embodiment of the present invention also provides a method for preparing the above-mentioned double-layer co-extruded aluminum-wood-plastic profile, comprising the ...

Embodiment 2

[0088] On the basis of above-mentioned embodiment 1

[0089] The raw material of described ethylene-1-butene copolymer layer is composed as follows by weight percentage:

[0090] Ethylene-1-butene copolymer 95%, antioxidant 0.5%, tackifier 0.5%, toughening agent 1%, antifungal agent 2%, cooling masterbatch 1%.

[0091] Preferably, the antioxidant is tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, N,N'-bis-(3- (3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, A mixture of any two of tris[2.4-di-tert-butylphenyl]phosphite; antioxidants can inhibit or delay the oxidative degradation of plastics and prolong their service life.

[0092] Described toughening agent is a low-temperature toughening agent, and described low-temperature toughening agent is polysiloxane and polycarbonate copolymer, melt index is 1 (300 ℃ / 1.2kg test), silicon content is 20%; Tougheners ar...

Embodiment 3

[0096] On the basis of above-mentioned embodiment 1 or 2

[0097] The raw materials of the wood-plastic material are composed as follows by weight percentage:

[0098] HDPE resin 50%, wood powder 43.7%, lubricant 0.7%, ultraviolet absorber 1.3%, antioxidant 1.5%, regulator 0.5%, anti-shrinkage agent 0.5%, compatibilizer 1.5%, anti-fungal agent 0.3%.

[0099] In this example, in the above-mentioned preparation method, the temperatures of each zone of the co-extrusion equipment are shown in Table 1.

[0100] Table 1

[0101]

[0102]

[0103] Described lubricant is PE wax;

[0104] Preferably, the antioxidant is tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, N,N'-bis-(3- (3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, n-octadecyl β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, A mixture of any two of tris[2.4-di-tert-butylphenyl]phosphite;

[0105] Described fungicide is zinc borate;

[0106] The ultraviolet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com