Car brake pad surface defect detecting and automatic sorting system based on machine vision

A technology of automatic sorting system and machine vision system, which is applied in the direction of sorting, optical testing for defects/defects, instruments, etc., can solve the problems of high work intensity, large detection amount, poor detection stability, etc., and is beneficial to use and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

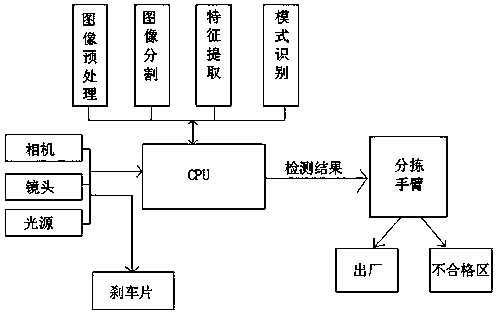

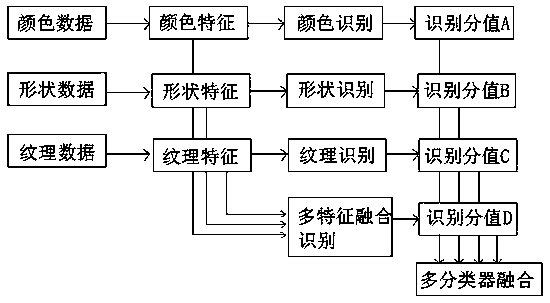

[0019] refer to Figure 1-2 , the present embodiment proposes an automatic sorting system for detecting surface defects of automobile brake pads based on machine vision. Picking the arm, the upper computer includes image preprocessing, image segmentation, feature extraction and pattern recognition, pattern recognition includes color recognition, shape recognition, texture recognition and multi-feature fusion recognition. The brake pads are tested, and the detection results are used to control the action of the sorting arm, and the defective brake pads are sorted to the unqualified area, and the qualified products are processed in the factory, so as to achieve the purpose of automatic sorting and facilitate use.

[0020] In this embodiment, the machine vision system detects the image of the object to be sorted and transmits the information to the CPU. The CPU processes the received information, and the CPU transmits the information to the host computer. The host computer perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com