Low-boiling-point ester and glycerol separation device for biodiesel distillation process

A separation device and glycerin technology, applied in liquid separation, separation method, fractionation, etc., can solve the problems of poor glycerin separation effect, unfavorable crude glycerin production, unqualified quality, etc., to ensure stability, simple structure, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

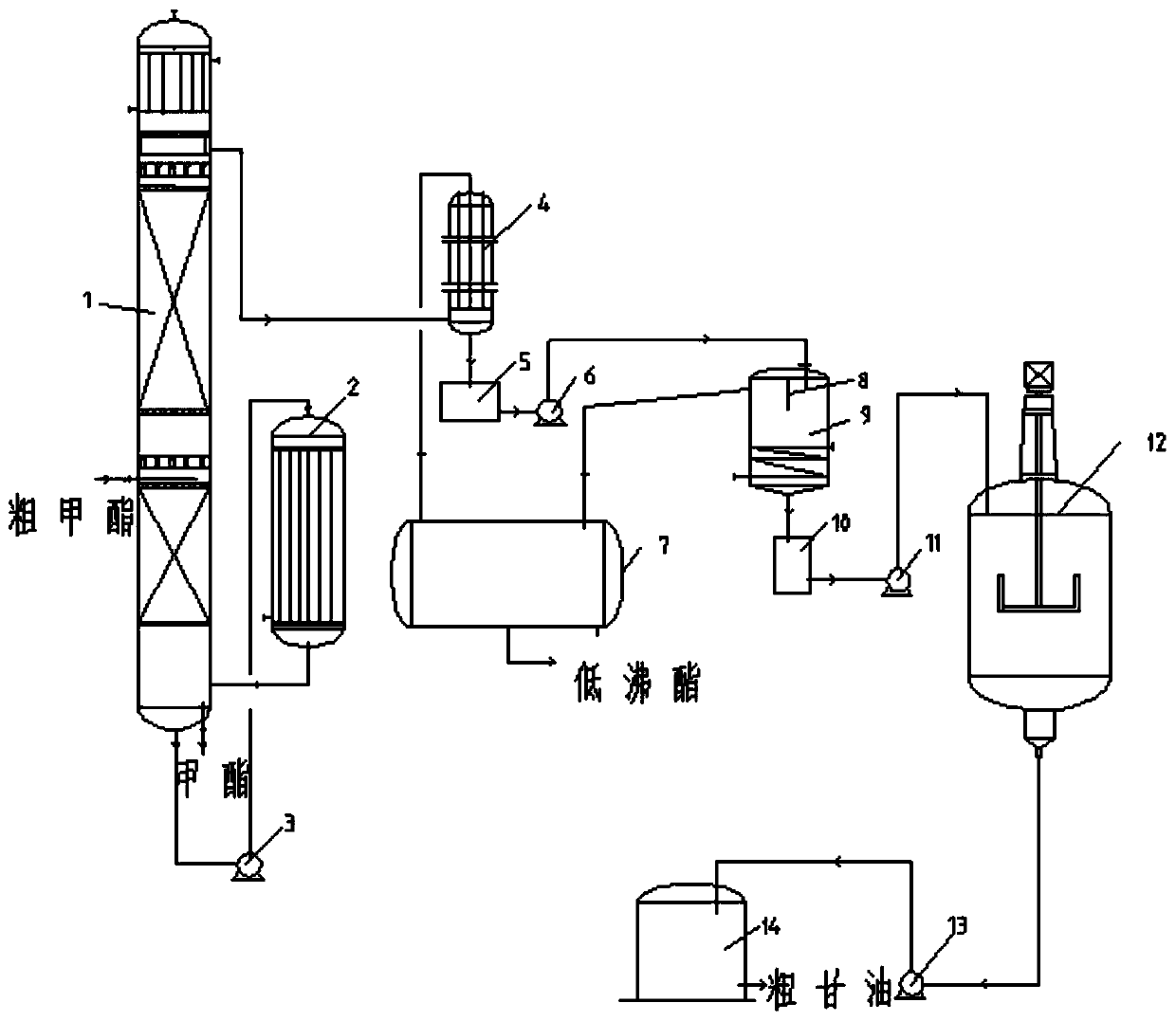

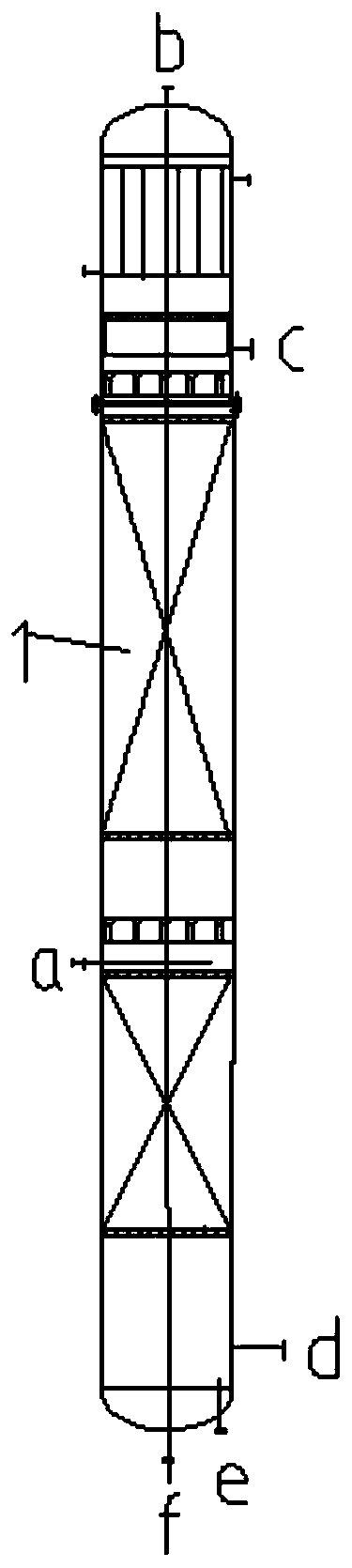

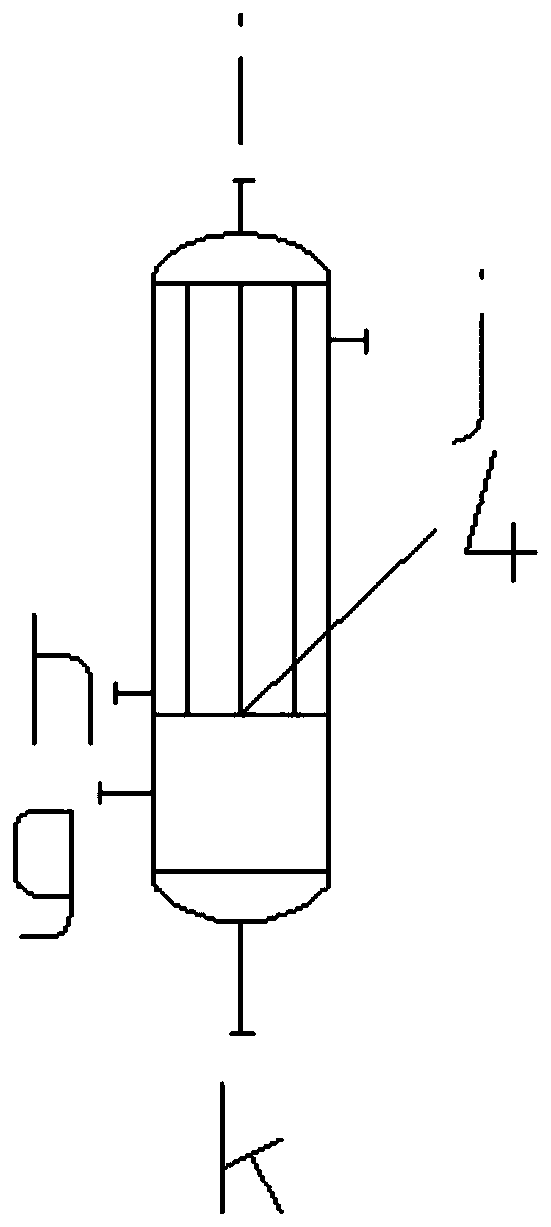

[0018] The device for separating low-boiling ester and glycerol in the biodiesel distillation process of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Figure 1-Figure 4 As shown, the biodiesel distillation process low-boiling ester and glycerin separation device of the present invention includes a distillation tower 1, a reboiler 2, a distillation tower circulation pump 3, a vertical cooler 4, a glycerin separation receiving tank 5, and a glycerin separation receiving tank pump 6 , low-boiling ester receiving tank 7, glycerin separator 9, glycerin barrel 10, separator glycerin pump 11, neutralization tank 12, neutralization tank outlet pump 13 and glycerin receiving tank 14; the inlet of the distillation tower circulation pump 3 passes The pipeline is connected to the bottom of the distillation tower 1, the outlet is connected to the top inlet of the reboiler 2 through the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com