Novel roller way transmission structure of solar cell roller way furnace

A technology of solar cells and transmission structures, which is applied in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as rear-end collision of cells, affecting the sintering effect of cells 5, and the effect of irradiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment:

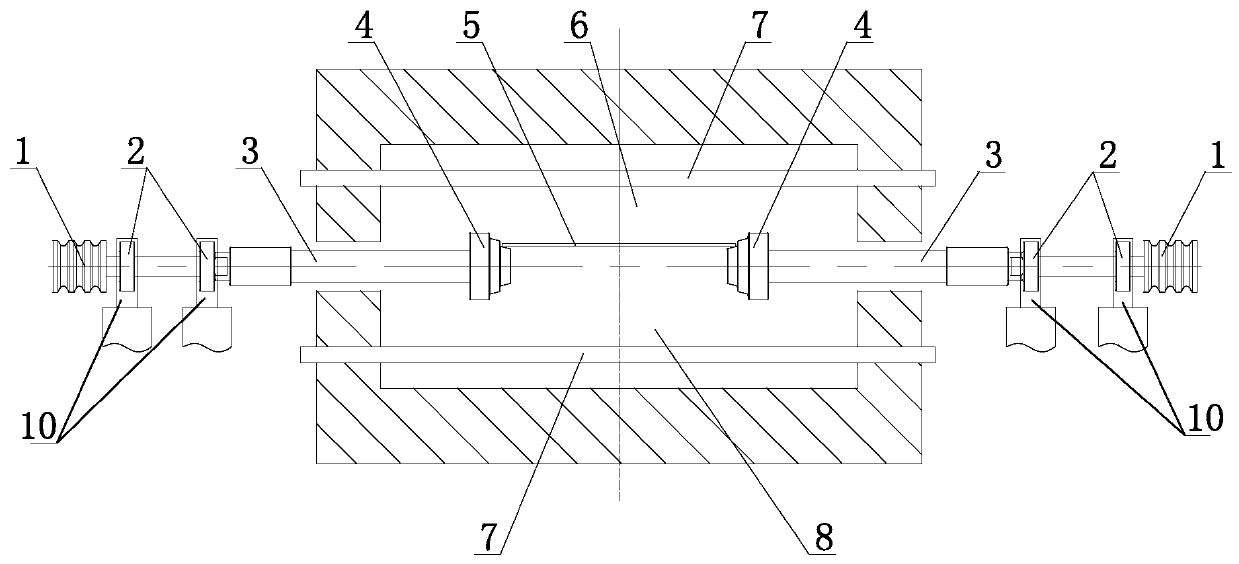

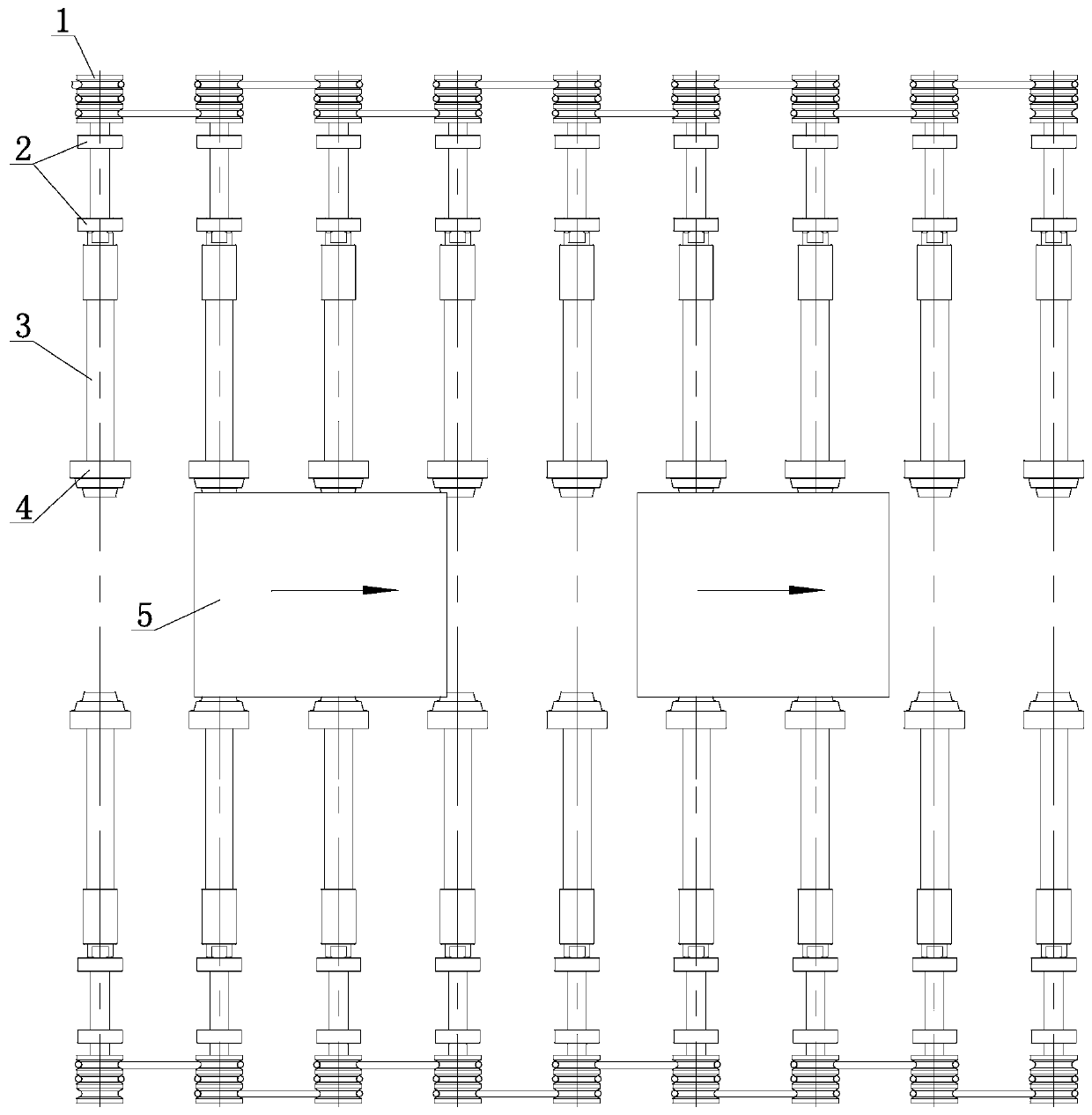

[0028] Such as Figure 1~4 As shown, in the novel roller conveyor structure of the solar battery roller furnace according to the present invention, a number of roller conveyors 3 are arranged in the furnace body, and the roller conveyors 3 are arranged on both sides of the furnace body, and intervals are provided between the roller conveyors 3 on both sides. The size of the interval matches the size of the battery sheet 5 .

[0029] Wherein, each roller table 3 is supported by two bearings 2, the bearings 2 are fixed on the bearing support base 10, the bearing support base 10 can be arranged on the slide rail, the bearing support base 10 can be adjusted left and right and fixed, by adjusting the bearing support The position of the seat 10 is used to adjust the size of the gap to match the size of the battery sheet 5 .

[0030] In this embodiment, the roller tables 3 are arranged sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com