Temperature control equipment and heat exchange unit thereof

A technology of heat exchange unit and temperature control equipment, which is applied in the direction of lighting and heating equipment, electrical equipment structural parts, electrical components, etc., and can solve problems such as increased costs, assembly errors, and increased man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the temperature control device and the heat exchange unit according to the present invention will be described below with reference to the relevant drawings, wherein the same components will be described with the same reference numerals.

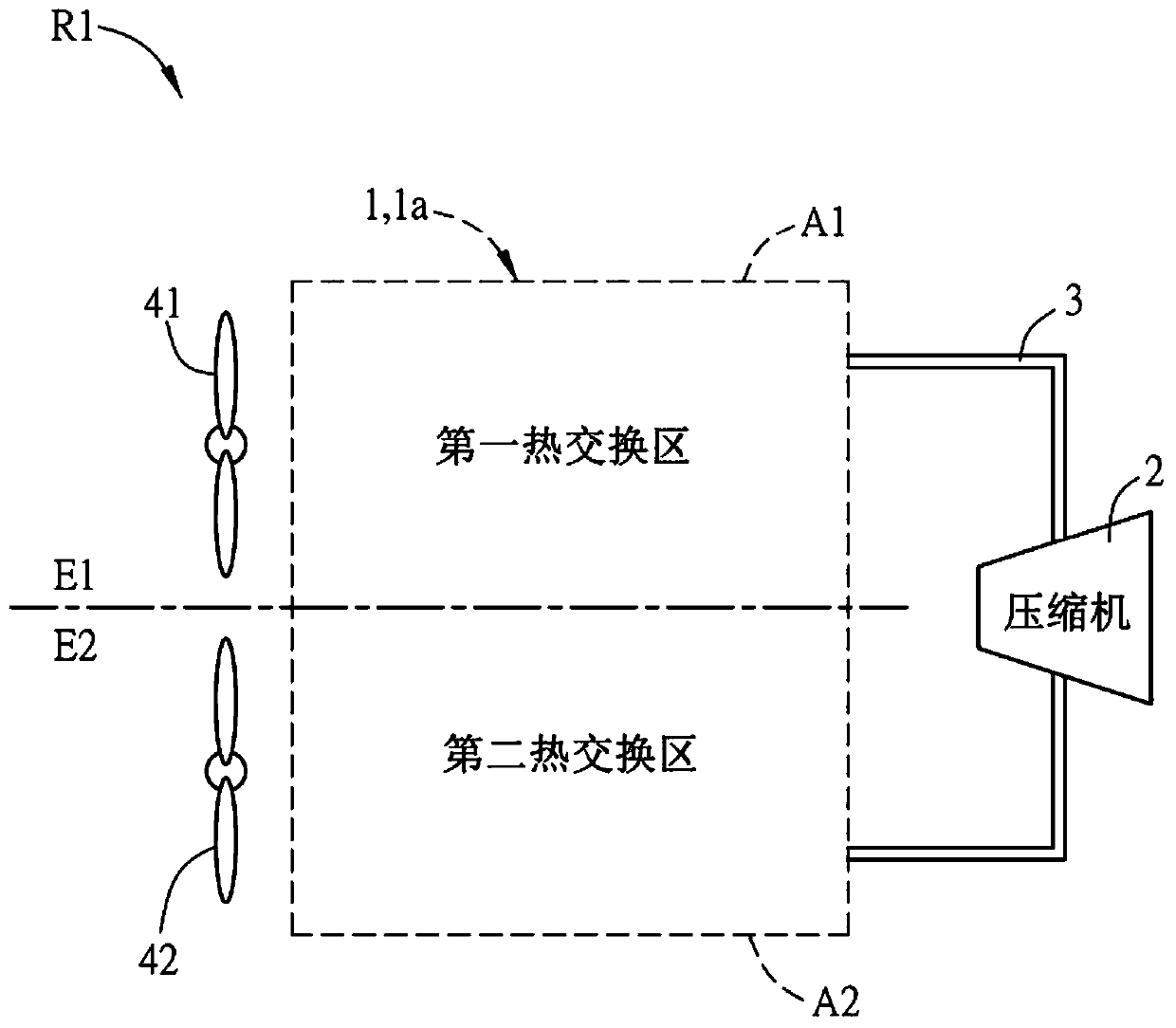

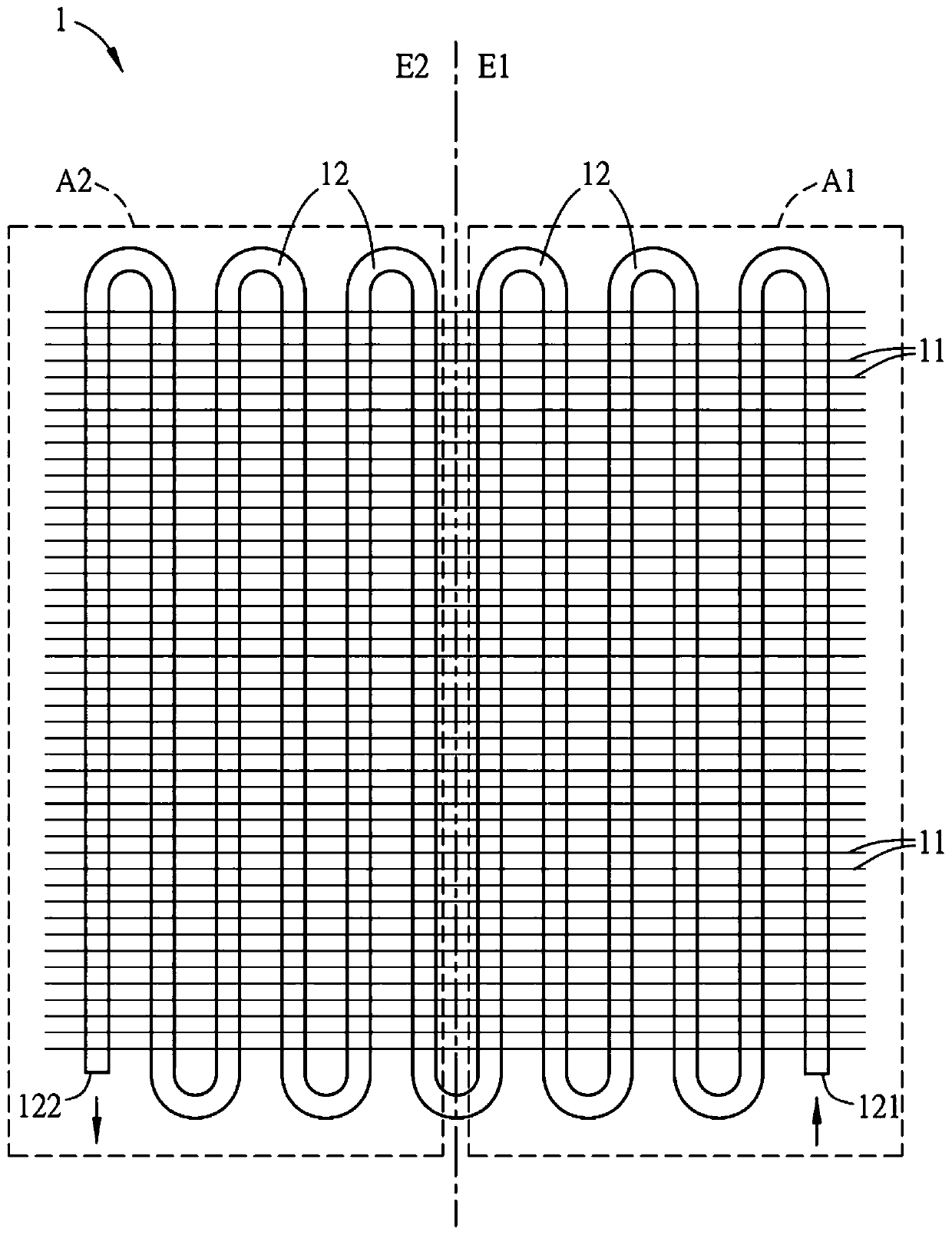

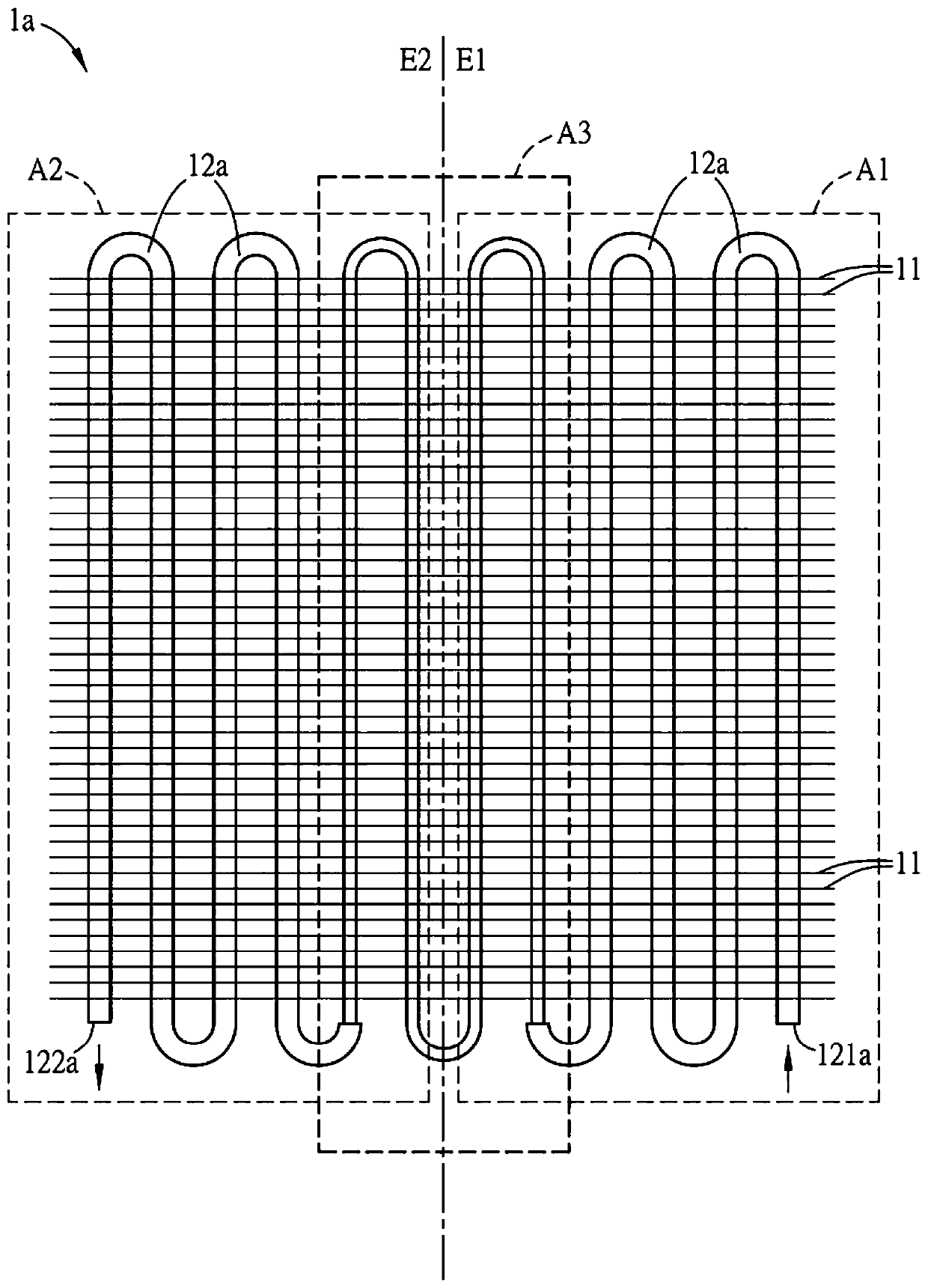

[0042] Please refer to figure 1 and Figure 2A , figure 1 It is a schematic diagram of a preferred embodiment of the temperature control device R1 of the present invention. The temperature control device R1 in the figure is set in the first environment E1 and the second environment E2. The temperature control device R1 includes a heat exchange unit 1 / 1a, a compressor 2, a circulation loop 3 and a working fluid. The heat exchange unit 1 / 1a is divided into a first heat exchange area A1 and a second heat exchange area A2.

[0043] Please refer to Figure 2A and also refer to figure 1 , Figure 2A for figure 1 A schematic diagram of a first embodiment of the heat exchange unit 1 of the temperature contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com