A method for the continuous production of polycarbonate-polyether polyols in a pipeline by a preheating liquid phase method

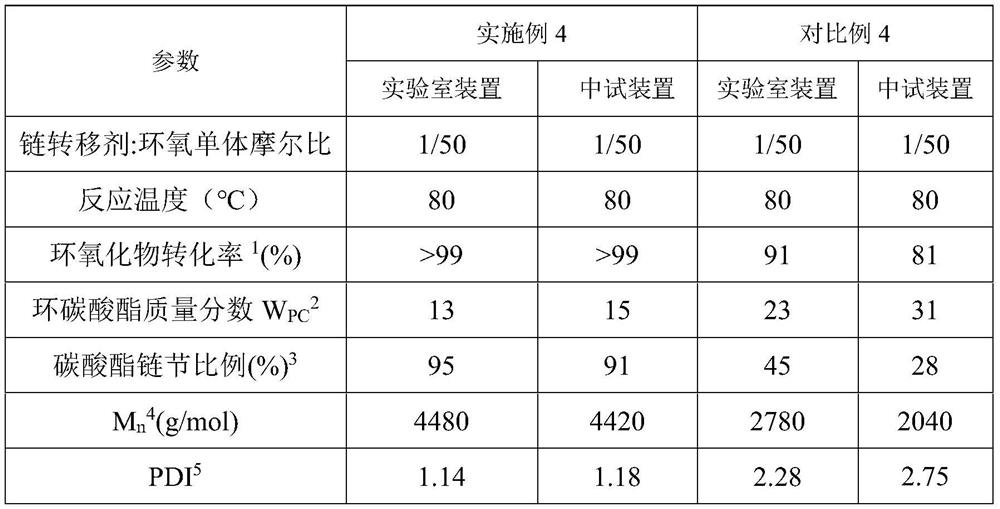

A technology of polyether polyol and polycarbonate, which is applied in the field of pipeline continuous production of polycarbonate-polyether polyol by preheating liquid phase method. To solve the problem of high carbonate ratio, to achieve the effect of inhibiting the formation of polyether and cyclic carbonate, improving the mass transfer and heat transfer ability and effect, and increasing the content of carbonate units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for pipelined continuous production of polycarbonate-polyether polyols by a preheating liquid phase method,

[0049] The method comprises the steps of:

[0050] (1) Put the raw materials including epoxy compound, catalyst and chain transfer agent into the premixing tank in a certain proportion and mix them evenly, then pump them into the pipeline reactor, the pipeline reactor includes a reaction section group and a cooling section group , the reaction section group is placed at the inlet end of the piped reactor, and the cooling section group is placed at the outlet end of the piped reactor;

[0051] (2) After carbon dioxide is preheated to 50-120°C, it is pumped in from the inlet of the pipeline reactor, so that the pipeline reactor is pressurized to 1-15MPa;

[0052] (3) The raw materials are mixed into a reaction solution in a pipelined reactor, heated to 70-150° C., so that in the presence of the catalyst, the chain transfer agent, epoxy compound and carbo...

Embodiment 2

[0084] Example 2 refers to Experimental Example 1. The difference is that in Example 2, carbon dioxide preheated to 50-120° C. is added from the heating section group to the pipelined reactor. The purpose of carbon dioxide heated to about 100°C is to, by adding preheated carbon dioxide, on the one hand, control the polymerization reaction temperature in the pipeline reactor relatively quickly, and on the other hand, avoid the dead zone in the pipeline reactor, so that the reaction The raw materials of the segment group are mixed evenly to avoid the enrichment of epoxy compounds, thereby avoiding the homopolymerization reaction between epoxy compounds.

Embodiment 3

[0094] Example 3 refers to Experimental Example 1, the difference is that in Example 3, in Example 3, an epoxy compound preheated to 50-120° C. is added from the reaction section group to the pipelined reactor , specifically, the addition of epoxy compound preheated to about 90°C aims to, on the one hand, control the polymerization reaction temperature in the pipeline reactor relatively quickly, and on the other hand, make the raw materials of the reaction section group mix evenly , to avoid dead zones in the piped reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com