Synthesis method of intermediate bis(carboxylcyclopentadiene)iron

A technology of cyclopentadiene, synthesis method, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problem of slow reaction, low yield and limited large-scale industrial application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

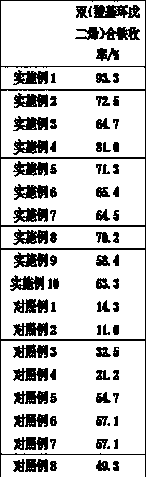

Examples

Embodiment 1

[0018] 1. A synthetic method for intermediate bis(carboxycyclopentadiene)iron, characterized in that the method comprises the following steps:

[0019] Step 1. Dissolve 1mol of 1,1'-diacetylferrocene and 2.5mol of cuprous chloride in 350ml of [C 5 mim]HSO 4 In the ionic liquid, after stirring and reacting at 50°C for 1h, the temperature was raised to 95°C and then stirred for 1h;

[0020] Step 2. After cooling, add 150ml of [C 5 mim]HSO 4 The ionic liquid is continuously stirred at a certain temperature, and the solution of the product is obtained after the reaction is completed;

[0021] Step 3, filter the solution of the product while it is hot, and the filtrate is acidified to pH=2 with concentrated hydrochloric acid, a large amount of yellow precipitates are formed, and the crude product is obtained after suction filtration;

[0022] Step 4, put the obtained product in a beaker, add 10% NaOH solution to dissolve all the product;

[0023] Step 5, filter the solution, a...

Embodiment 2

[0031] Step 1. Dissolve 0.8mol of 1,1'-diacetylferrocene and 2.5mol of cuprous chloride in 350ml of [C 5 mim]HSO 4 In the ionic liquid, after stirring and reacting at 50° C. for 1 h, the temperature was raised to 95° C. and then stirred for 1 h; the rest of the steps were the same as in Example 1.

Embodiment 3

[0033] Step 1. Dissolve 0.6mol of 1,1'-diacetylferrocene and 2.5mol of cuprous chloride in 350ml of [C 5 mim]HSO 4 In the ionic liquid, after stirring and reacting at 50° C. for 1 h, the temperature was raised to 95° C. and then stirred for 1 h; the rest of the steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com