A method for preparing layered nano-carbon materials by solvent heat treatment of coal

A technology of layered nano and carbon materials, applied in the direction of nano carbon, etc., to achieve the effect of fast decomposition and low initiation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

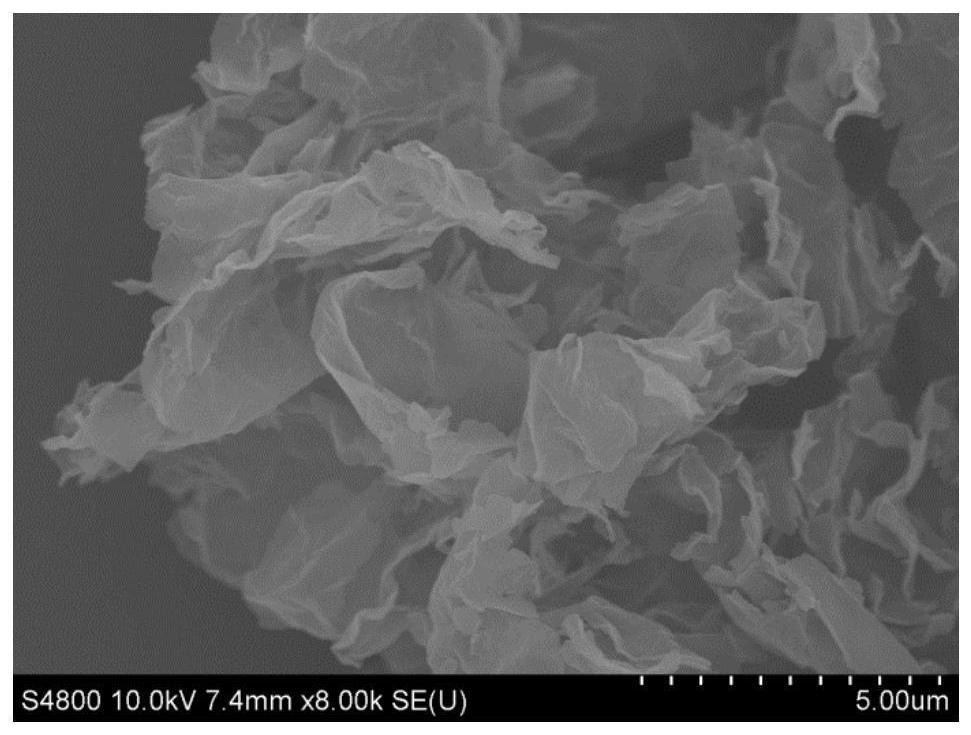

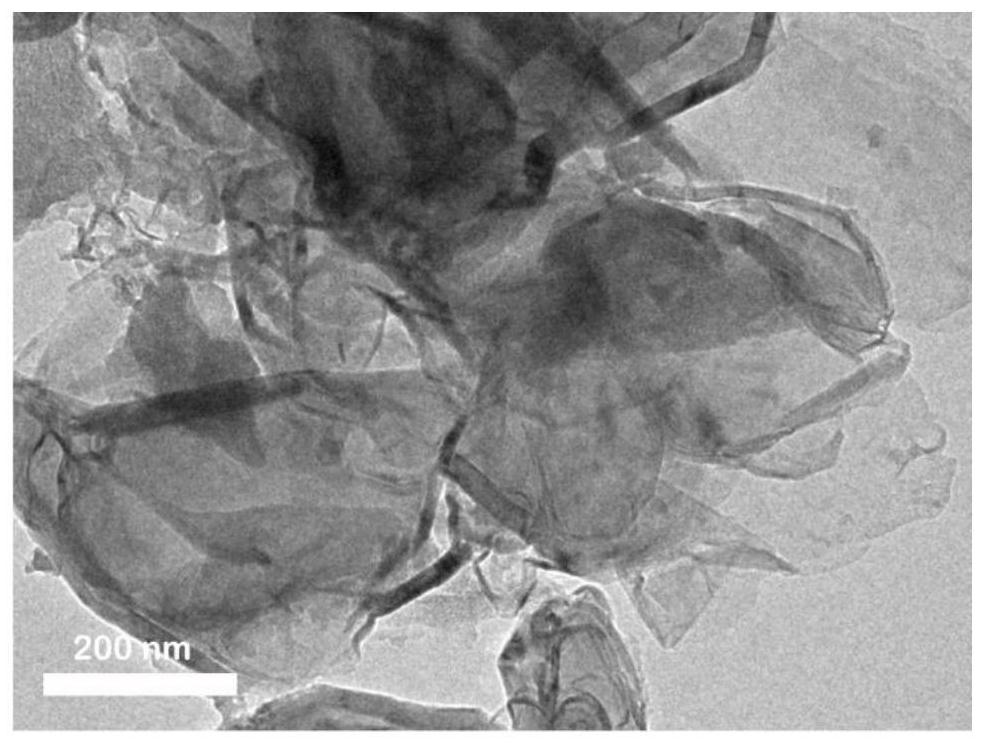

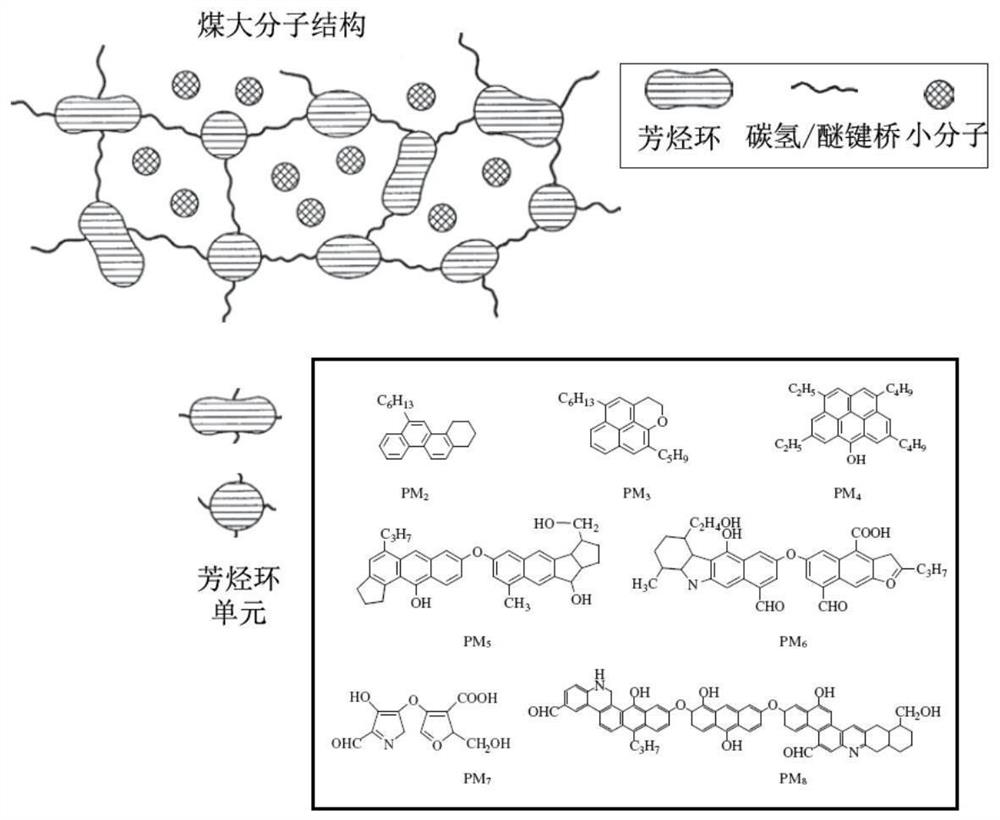

[0065] Ash-free lignite is selected as the raw material, and the massive raw coal is crushed by mechanical crushing, and then sieved to control the particle size below 0.15mm. The pulverized raw coal was treated with 25 times deionized water in an ultrasonic cleaner (20 kHz) for 30 minutes, filtered and then dried in a drying machine at 110° C. until the water content was lower than 5%. Coal powder is mixed with benzyl alcohol-benzyl ether solvent to form coal slurry, which is then heated in a closed high-pressure reactor.

[0066] The molar ratio of the benzyl alcohol-benzyl ether solvent and the composition of the coal slurry are shown in Table 3. 400ml of coal slurry was injected into a 1L stainless steel reaction kettle, and the air was exhausted with nitrogen after sealing. The temperature of the coal slurry is raised to 380°C, the stirring rate is 300r / min, and the treatment time is 2.5h.

[0067]The solvent and low boilers are separated off after the liquefaction proce...

Embodiment 2

[0073] Ash-free lignite is selected as the raw material, and the massive raw coal is crushed by mechanical crushing, and then sieved to control the particle size below 0.15mm. The pulverized raw coal is treated with 25 times of deionized water in an ultrasonic cleaner (20kHz) for 30 minutes, filtered and dried at 110°C until the water content is lower than 5%; coal powder is mixed with benzyl alcohol-benzyl ether solvent to form a coal slurry , followed by heat treatment in a closed autoclave.

[0074] The molar ratio of benzyl alcohol-benzyl ether solvent is 1:1, the mass ratio of solvent to coal powder is 4:1, 400ml of coal slurry is injected into a 1L stainless steel reaction kettle, and the air is exhausted with nitrogen after sealing. Solvothermal treatment conditions are shown in Table 4.

[0075] The solvent and low boilers are separated off after the liquefaction process. Take 10g coal solvent heat treatment product, mix with 140ml oxidant (containing 23% nitric acid...

Embodiment 3

[0082] Ash-free lignite is selected as the raw material, and the massive raw coal is crushed by mechanical crushing, and then sieved to control the particle size below 0.15mm. The pulverized raw coal was treated with 25 times deionized water in an ultrasonic cleaner (20 kHz) for 30 minutes, filtered and then dried in a drying machine at 110° C. until the water content was lower than 5%. Coal powder is mixed with benzyl alcohol-benzyl ether solvent to form coal slurry, which is then heated in a closed high-pressure reactor.

[0083] The molar ratio of benzyl alcohol-benzyl ether solvent is 3:1, the mass ratio of solvent to coal powder is 6:1, 400ml of coal slurry is injected into a 1L stainless steel reaction kettle, and the air is exhausted with nitrogen after sealing.

[0084] The solvent and low boilers are separated off after the liquefaction process. Take 10g of the coal solvent heat treatment product and mix it with 140ml of oxidant. The oxidation treatment conditions ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com