Release liners for laser cut adhesives

A release liner, adhesive layer technology, applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as damage to the adhesive layer, and achieve low The effect of peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

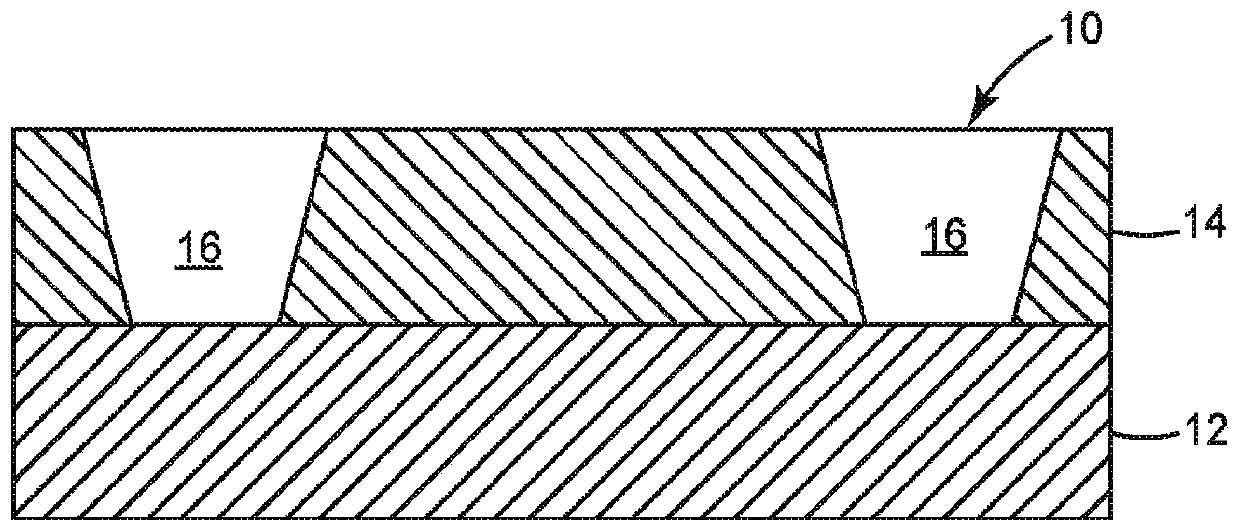

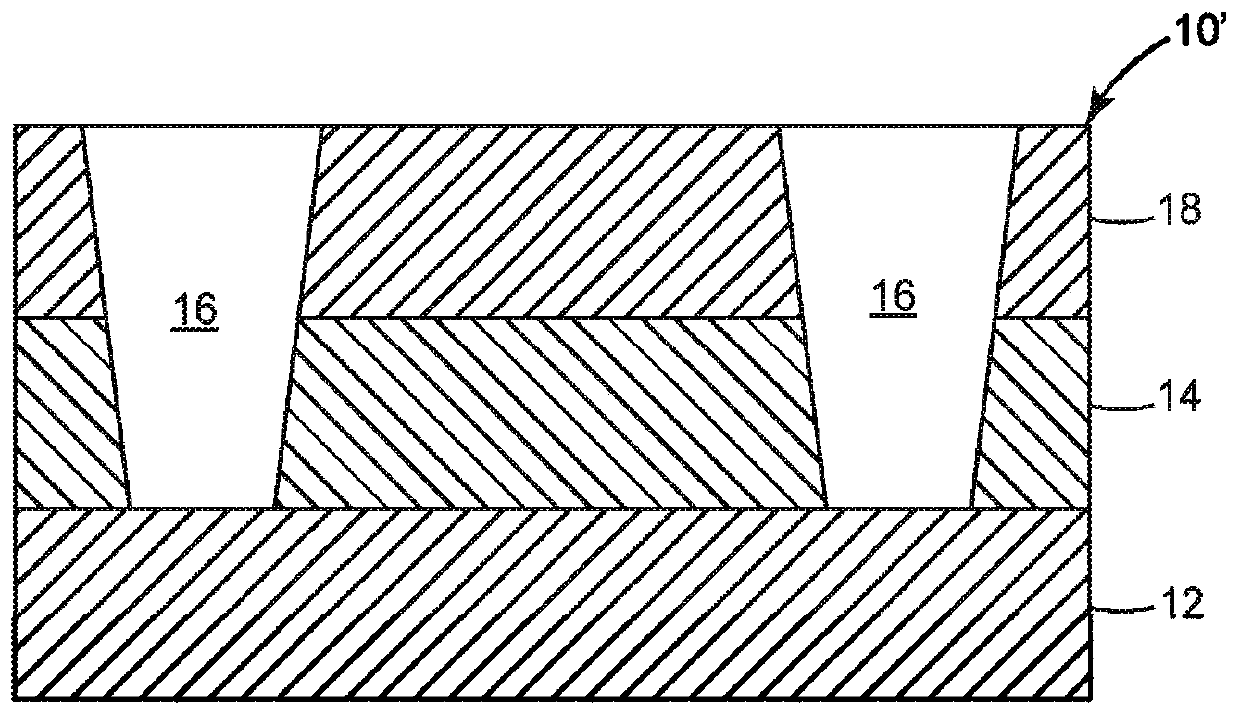

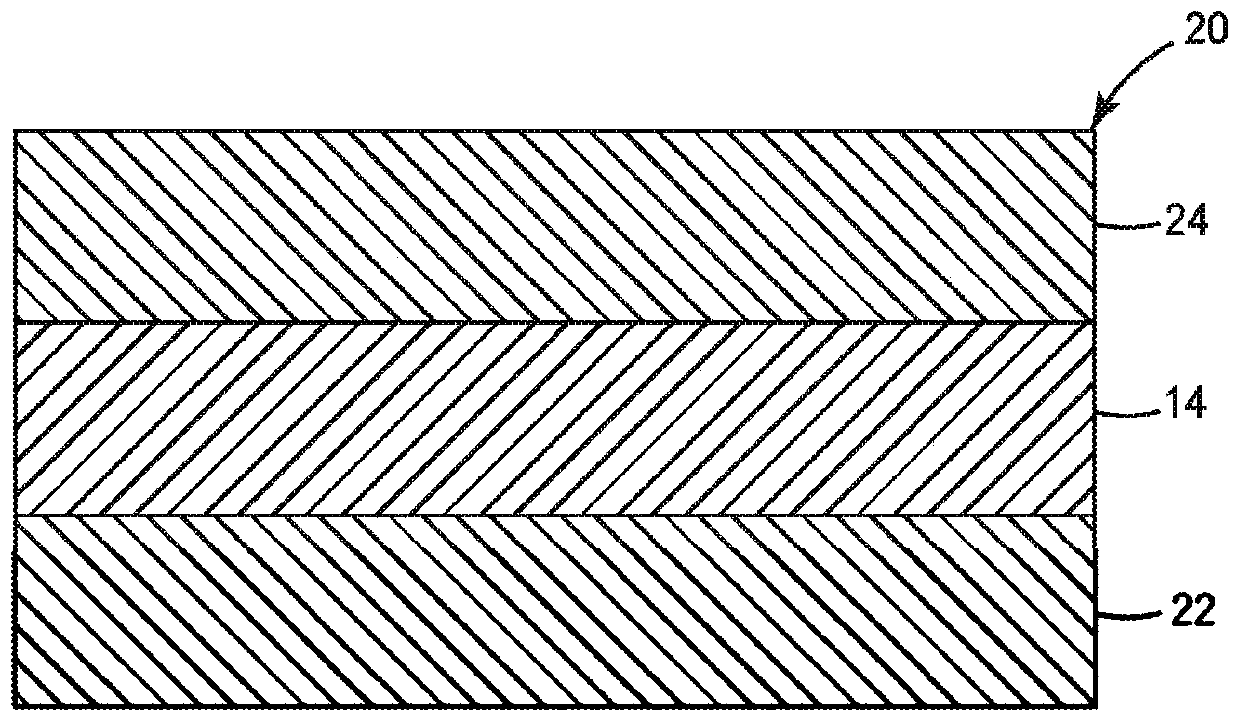

[0123] Adhesive layer 14 is a 25 micron acrylic foldable component layer as described in PCT Patent Publication No. WO 2016 / 196541 (Behling et al.), the disclosure of which is incorporated herein by reference, entitled "Example 7- 20: Preparation of solvent-free based component layer samples" and details are those of Example 8 in Table 3. The adhesive is in the form of a laminate 10' between a 75 micron silicone coated low peel secondary liner 18 that adheres to standard substrates such as polyethylene (PET) (the composite will be the device specific) (obtained from SKC Haas, Seoul, South Korea (SKCHaas, Seoul, South Korea) under the trade designation "RF02N") and 100 microns of addition cured silicone release-coated biaxially oriented polypropylene (BOPP) low Between the release type first liner 12.

[0124] The laminate was exposed to sufficient laser electromagnetic radiation to produce a 25.4 mm x 203.2 mm rectangular continuous profile cut through the second release line...

Embodiment 2

[0127] Example 2 was prepared as described in Example 1 except that the adhesive was in the form of a laminate 10' between a 75 micron silicone coated PET low peel secondary liner 18 (RF02N) and 100 Micron addition cured silicone release coated BOPP high release first liner 12 between.

Embodiment 3

[0129] Example 3 was prepared as described in Example 1, except that the adhesive was in the form of a laminate 10", between a 75 micron silicone-coated PET low-release secondary liner 18 (RF02N) and 75 Micron silicone coated PET high release first liner 12 (available from SKC Haas under the trade designation "RF12N").

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com