A bench type transformer lead wire intelligent production system and its working method

A technology of intelligent production and transformers, which is applied in the direction of inductance/transformer/magnet manufacturing, connection, circuit/collector components, etc., can solve the problems of waste of raw materials, complicated wire manufacturing process, and failure to meet design standards, etc., to reduce turnover Time and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

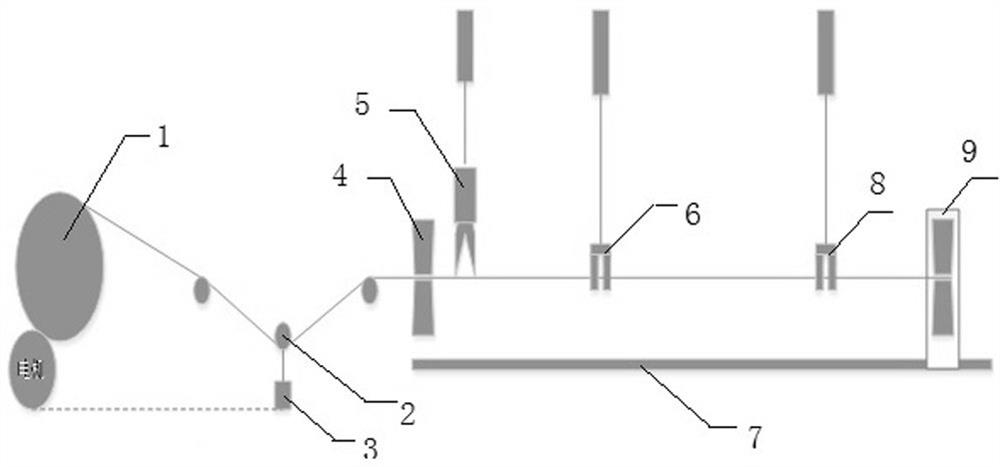

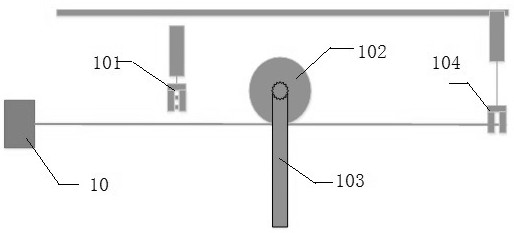

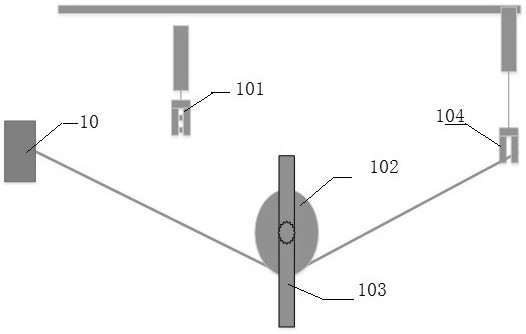

[0040] Embodiment 1: as figure 1 and Figure 7As shown, a bench-type transformer lead wire intelligent production system includes an automatic wire cutting mechanism, a cable shaping mechanism, a pneumatic stripping machine, and a pneumatic crimping machine. The automatic wire cutting mechanism cuts the cables according to the specifications and sends them to the line The cable shaping mechanism performs bending and shaping processing. The cable after bending and shaping in the cable shaping mechanism is sent to the pneumatic stripping machine for peeling treatment. The automatic wire cutting mechanism is connected with the control cabinet, and the control cabinet is connected with the host computer through the communication cable. , The upper computer is equipped with a touch screen, on which the cutting length, cutting quantity and cable pay-off speed can be set. The whole equipment is automatically controlled by the PLC controller in the control cabinet.

[0041] The autom...

Embodiment 2

[0047] Embodiment 2: A working method of a bench-type transformer lead wire intelligent production system, comprising the following steps:

[0048] S1. First, the cable reel is hung on the output shaft of the wire wheel motor 11 in the automatic wire cutting mechanism, and then the cable is manually passed through the first guide wheel, the tension wheel 2 and the second guide wheel in the automatic wire cutting mechanism, Insert the cable into the first pneumatic clamp 4, and use the first pneumatic clamp 4 to clamp the cable;

[0049] S2, then set the cutting length, cutting quantity and cutting speed through the host computer, start the pneumatic scissors 5, the first pneumatic wire taker 6 and the second pneumatic wire taker 8 to leave the station;

[0050] S3. At this time, the built-in collet in the first wire puller 9 in the automatic wire cutting mechanism is released, and the action of the sliding module of the first wire puller 9 in the automatic wire cutting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com