Rolling shaft type pay-off device and pay-off method

A wire pay-off device and roller technology are applied in the directions of transportation and packaging, transportation of filamentous materials, cable laying equipment, etc., which can solve the problems of poor safety, inability to use, and high cost of crane pay-off, and prevent shaking and deviation. Easy installation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

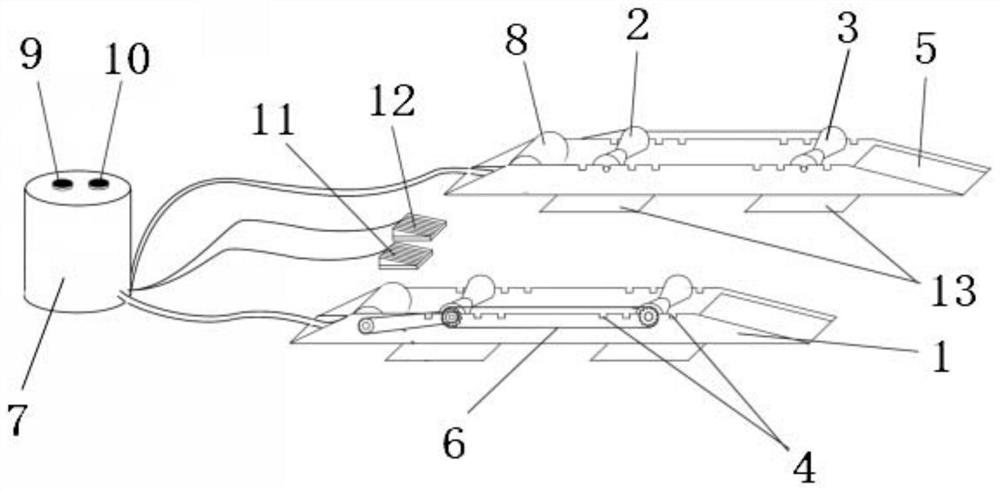

[0028] like figure 1 As shown, the present invention provides a roller type pay-off device, which mainly includes two bases 1 arranged at intervals on the left and right, and the distance between the two bases 1 is adjustable, and the base 1 is provided with a distance adjusting structure. The front roller 3 and the rear roller 2 are rotatably installed on the adjustment structure, and the front roller 3 and the rear roller 2 are arranged at intervals. Positioning structure, the front roller 3 and the rear roller 2 on the two bases 1 are driven by the drive unit to rotate synchronously; the front part of the base 1 is provided with an inclined running part 5, so as to facilitate the rolling of the pay-off roller through the running part 5 On the front roller 3 and the rear roller 2 on the upper part of the base 1, two independent bases 1 are provided and the distance between them is adjustable to adapt to pay-off rollers of different widths; by setting the distance adjustment ...

specific Embodiment approach 2

[0033] The present invention also provides a pay-off method for using the above-mentioned pay-off device, which mainly includes the following steps:

[0034] A1: Adjust the distance between the two bases 1 by moving the base 1 to adapt to the width of the pay-off roller;

[0035] A2: Select two adjustment grooves 4 with suitable spacing to install the front roller 3 and the rear roller 2 in them;

[0036] A3: Select a suitable first chain 6 to drive the front roller 3 and the rear roller 2 to connect;

[0037] A4: Manually roll the pay-off roller from the slope at the front of the base 1 to the front roller 3 and the rear roller 2 located on the upper part of the base 1 and support it on the positioning structure;

[0038] A5: Complete the pay-off operation by manually rotating the pay-off roller; or, drive the second chain and the first chain 6 to rotate through the DC motor 8 and then drive the front roller 3 and the rear roller 2 to rotate synchronously to realize the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com