Prefabricated type concrete floor plate environmental protection construction method

A prefabricated assembly and construction method technology, applied in the direction of floor slabs, manufacturing tools, building components, etc., can solve problems such as the inability to apply building structure floor slabs, and achieve the effects of environmental protection and energy saving of construction technology, reduction of construction period, and reasonable formulation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings.

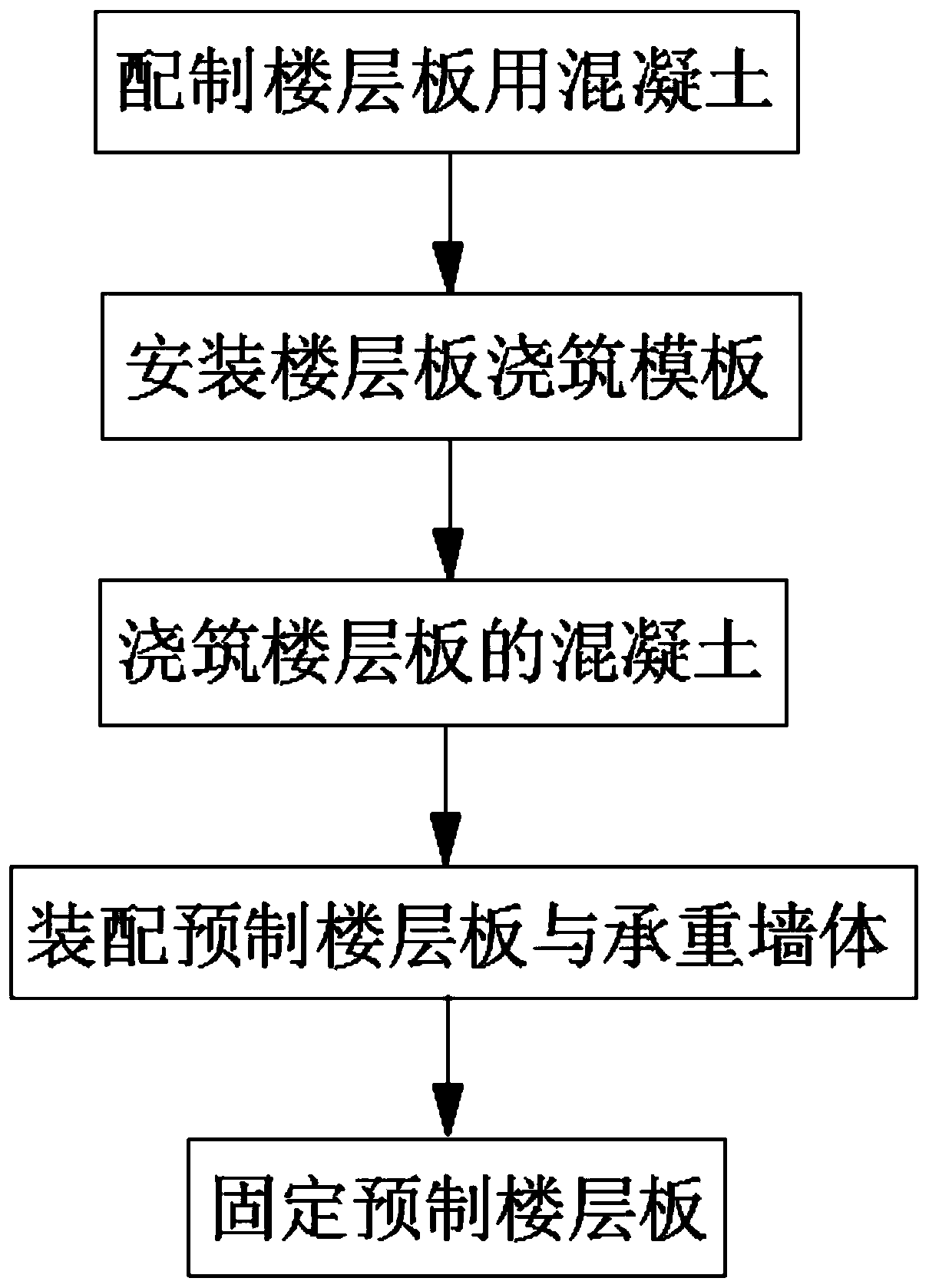

[0037] Reference figure 1 , figure 2 The present invention discloses an environmentally friendly construction method for prefabricated concrete floor slabs, which includes the following construction steps:

[0038] S1. Prepare concrete for floor slabs: put cement, water, fine coal gangue, blast furnace slag powder, cement accelerator, defoamer, and water reducer together into the concrete mixer, and the particle size of the fine coal gangue It is 2~4mm, the defoaming agent is a silicone defoaming agent, and the weight parts of each raw material input are 16:22:11:3.5:0.015:0.065:0.25, that is, concrete for floor slabs is obtained for use;

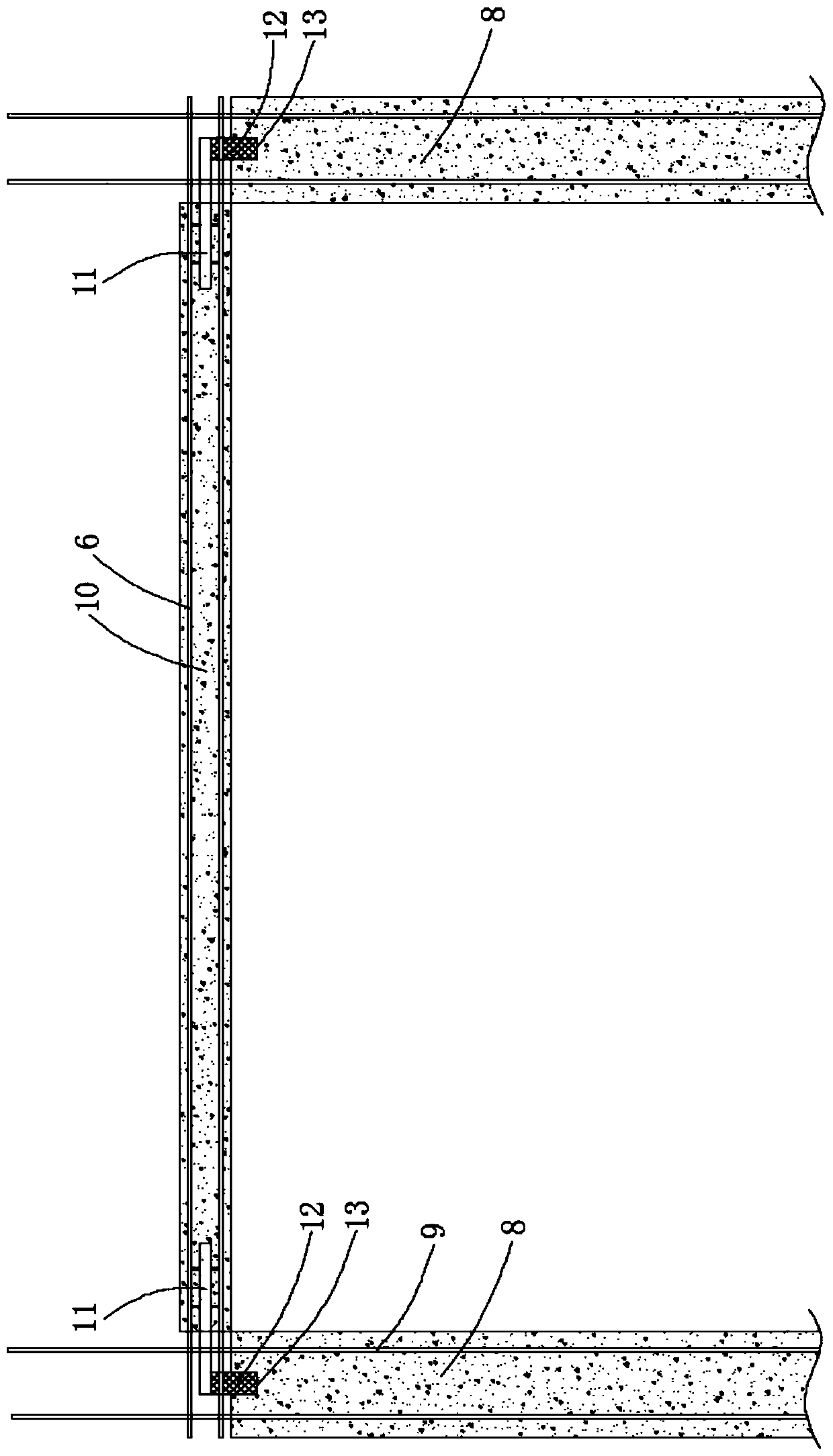

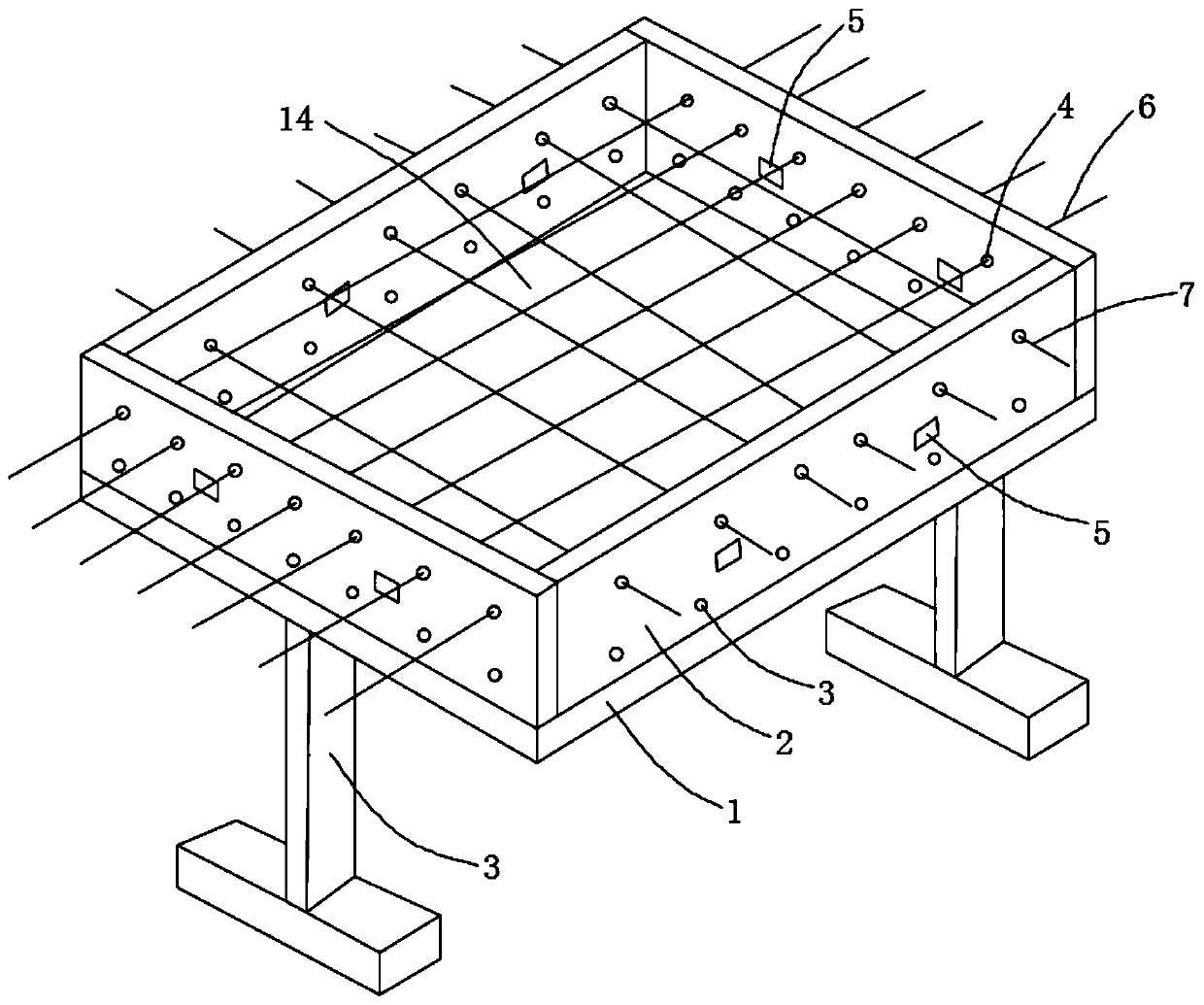

[0039] S2, install the floor slab pouring template 2: The cavity 14 used for pouring the precast floor slab 10 is composed of the bottom template 1, the pouring template on the left side 2, the pouring template on the right side 2, the pouri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com