Method for inhibiting arsenic hydride gas during sulfuric acid leaching of high-arsenic-lead-zinc smoke dust

A high-arsenic lead-zinc and arsenic hydrogen technology, applied in the field of non-ferrous metal metallurgy, can solve problems such as long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

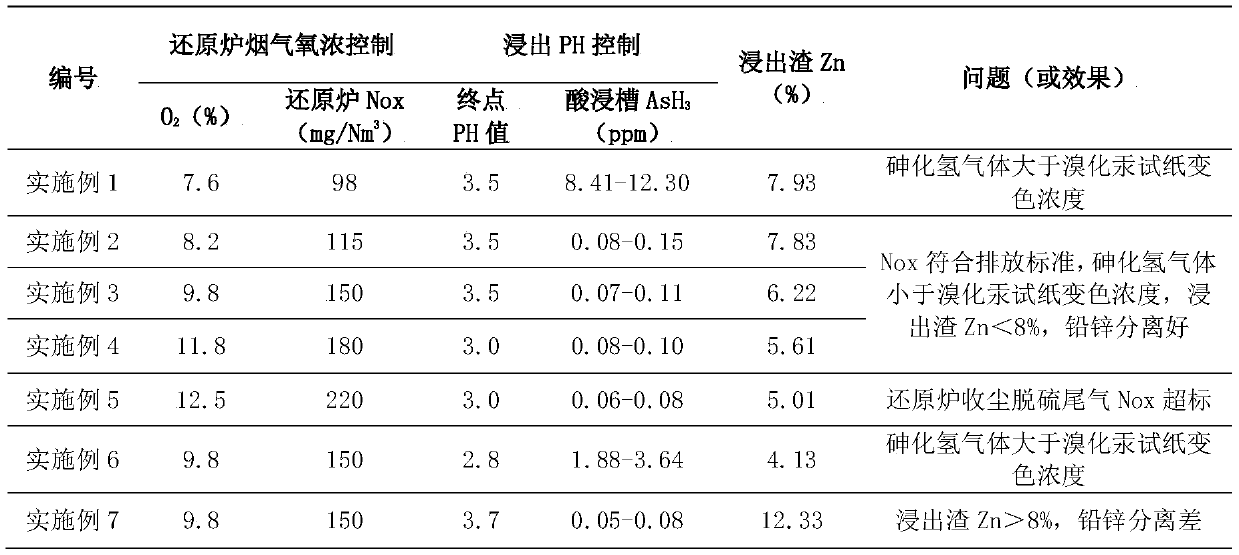

Embodiment 1

[0028] Control reduction furnace flue gas O 2 7.6%, NOx98mg / Nm from dust collection and desulfurization tail gas 3 (Emission standard≤200mg / Nm 3 ), the chemical analysis results of the output smoke and dust (%, wt): As4.12, Pb35.32, Zn36.61, S3.31; X-ray diffraction analysis results (%, wt): As 2 O 3 , ZnAsO 4 , ZnO, ZnS and metal elements exist in the form, arsenic metal element is 0.22, zinc metal element is 0.36; lead exists in the form of PbO, PbS and elemental Pb, of which elemental Pb is 7.62.

[0029] After slurrying the dust with clean water, 172.06g / L dilute sulfuric acid was continuously added to extract zinc. Before the pH value of the slurry reached 3.5, the measured AsH in the leaching tank was 3 The gas content is 1.42-7.46ppm, which is higher than the discoloration concentration of the mercury bromide test paper (the discoloration concentration of the mercury bromide test paper is ≥ 0.25ppm); when the pH of the leaching pulp reaches 3.5, the flow rate of dil...

Embodiment 2

[0032] Control reduction furnace flue gas O 2 8.2%, NOx 115mg / Nm in the exhaust gas from dust collection and desulfurization 3 (Emission standard≤200mg / Nm 3 ), the chemical analysis results of the output smoke and dust (%, wt): As3.95, Pb36.42, Zn34.16, S2.13; X-ray diffraction analysis results (%, wt): As 2 O 3 , ZnAsO 4 , ZnO and ZnS exist in the form of elemental arsenic 0.04, elemental zinc 0.05; lead exists in the form of PbO, PbS and elemental Pb, of which elemental Pb is 4.62.

[0033] After slurring the dust with clean water, continuously adding dilute sulfuric acid with a content of 142.31g / L to leaching zinc, before the pH value of the pulp reaches 3.5, the measured AsH in the leaching tank 3The gas content is 0.05-0.08ppm, which is lower than the discoloration concentration of the mercury bromide test paper (the discoloration concentration of the mercury bromide test paper is greater than or equal to 0.25ppm); when the pH of the leaching pulp reaches 3.5, adjust...

Embodiment 3

[0036] Control reduction furnace flue gas O 2 9.8%, NOx 150mg / Nm from dust collection and desulfurization tail gas 3 (Emission standard≤200mg / Nm 3 ), the chemical analysis results of the output smoke and dust (%, wt): As6.76, Pb40.63, Zn33.17, S1.82; X-ray diffraction analysis results (%, wt): As 2 O 3 , ZnAsO 4 , ZnO and ZnS exist, and no elemental arsenic and zinc are detected; lead exists in the form of PbO, PbS and elemental Pb, of which elemental Pb is 2.81.

[0037] After slurrying the smoke and dust with clean water, continuously adding dilute sulfuric acid with a content of 160.25g / L to leaching zinc, before the pH value of the pulp reaches 3.5, the measured AsH in the leaching tank 3 The gas content is 0.07-0.11ppm, which is lower than the discoloration concentration of the mercury bromide test paper (the discoloration concentration of the mercury bromide test paper is greater than or equal to 0.25ppm); when the pH of the leaching pulp reaches 3.5, the flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com