Polymer-based piezoelectric film, and preparation method and application thereof

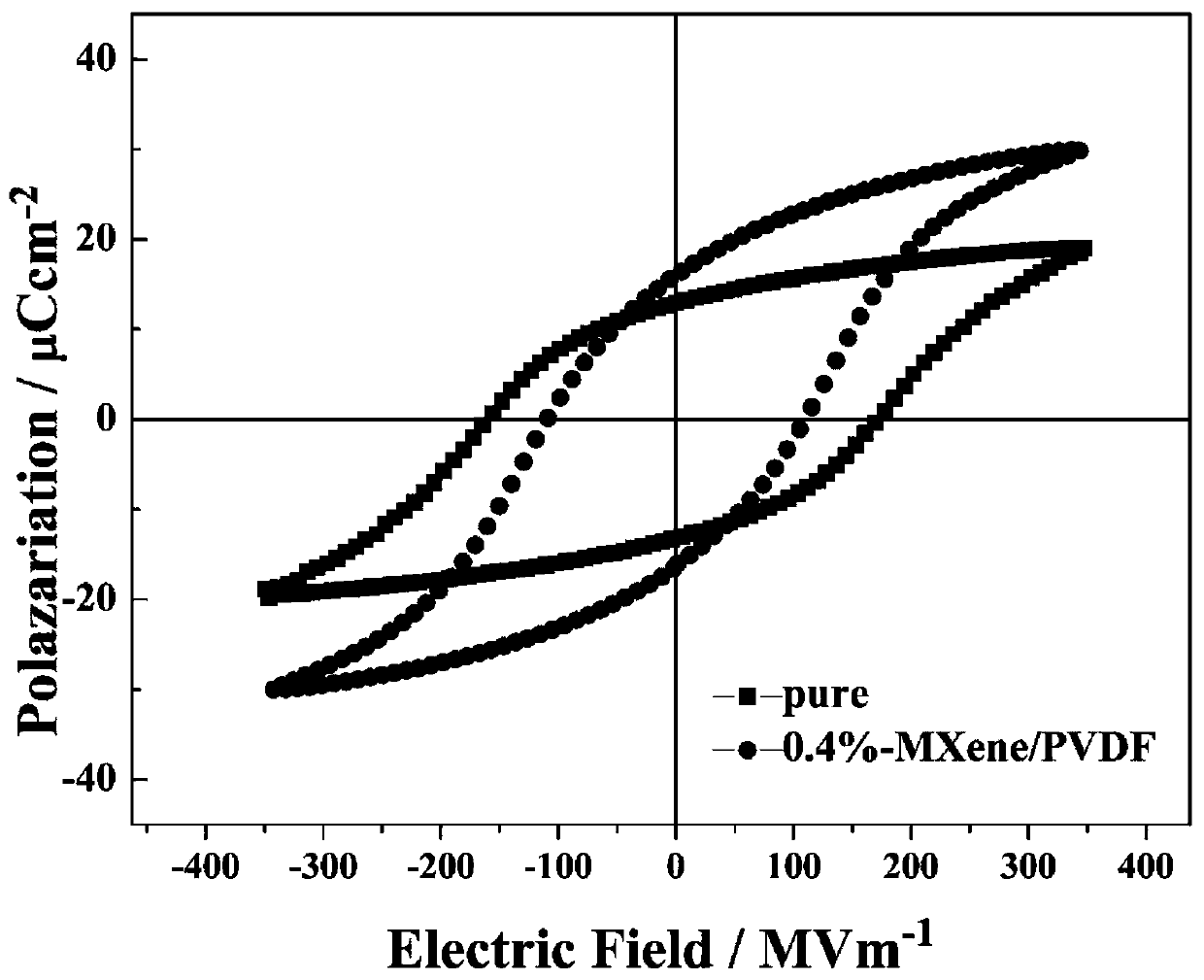

A polymer-based piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of piezoelectric performance and other problems, to achieve the effect of increased piezoelectric constant, increased polarization strength, and excellent ferroelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the polymer-based piezoelectric film described in the above technical solution, comprising the following steps:

[0039] Mix the polymer with the two-dimensional layered structure compound to obtain the spinning slurry;

[0040] The spinning slurry is subjected to electrospinning and first hot pressing in sequence to obtain an initial film;

[0041] The initial film is sequentially laminated, second hot pressed and rolled to obtain the polymer-based piezoelectric film.

[0042] In the present invention, unless otherwise specified, each component is a commercially available product well known to those skilled in the art.

[0043] In the invention, the polymer is mixed with a two-dimensional layer structure compound to obtain a spinning slurry.

[0044] In the present invention, the polymer is preferably added in the form of a polymer solution. In the present invention, the solvent of the polymer solution is pr...

Embodiment 1

[0058] Add 1.4g of PVDF into 6g of DMF solvent, heat and stir in a magnetic stirring heater at 65°C for 6h to obtain a polyvinylidene fluoride solution;

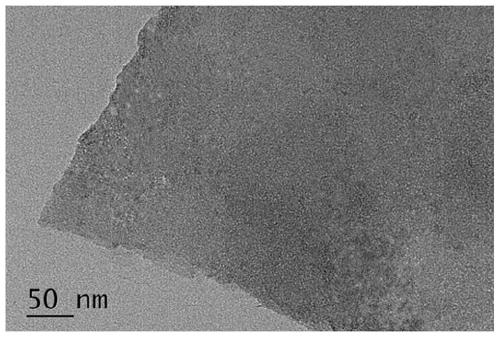

[0059] 0.0056g of Ti 3 C 2 Add the nanosheets into 6g of DMF solvent, and ultrasonically disperse to obtain MXene solution;

[0060] Using an ultrasonic cleaning machine to ultrasonically mix the obtained polyvinylidene fluoride solution and MXene solution for 1 hour to obtain a preparation;

[0061] The obtained preparation is injected into the syringe, the pushing speed is set at 1.0mL / h, the voltage is 15kV, the humidity is controlled at 35%, the distance between the needle of the syringe and the receiving drum is 12cm, and the rotating speed of the receiving drum is 500rpm to obtain fibers; The first hot pressing is carried out under the conditions of 40MPa pressure and 300°C temperature to obtain an initial film with a thickness of 17 μm;

[0062] Laminate the initial films obtained from the three layers together, an...

Embodiment 2

[0080] Add 1.6g of PVDF into 6g of DMF solvent, heat and stir in a magnetic stirring heater at 65°C for 6h to obtain a polyvinylidene fluoride solution;

[0081] 0.0064g of Ti 3 C 2 Add the nanosheets into 6g of DMF solvent, and ultrasonically disperse to obtain MXene solution;

[0082] Using an ultrasonic cleaning machine to ultrasonically mix the obtained polyvinylidene fluoride solution and MXene solution for 1 hour to obtain a preparation;

[0083] The resulting preparation is injected into the syringe, set the push speed to 1.0mL / h, the voltage to 16kV, and the humidity to be controlled at 35%. The distance between the needle of the syringe and the receiving drum is 16cm, and the rotating speed of the receiving drum is 500rpm to obtain fibers; The first hot pressing is carried out under the conditions of 38MPa pressure and 250°C temperature to obtain an initial film with a thickness of 21 μm;

[0084] Laminate the initial films obtained from the three layers together, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com