A Conformal Measurement and Processing Control Method for Three-dimensional Round Jewelry

A control method and jewelry technology, applied in the direction of processing models, clothing, decorative arts, etc., can solve the problems of low scrap rate, high material consumption cost, high product scrap rate, etc., to improve processing accuracy, save material costs, and scrap rate. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

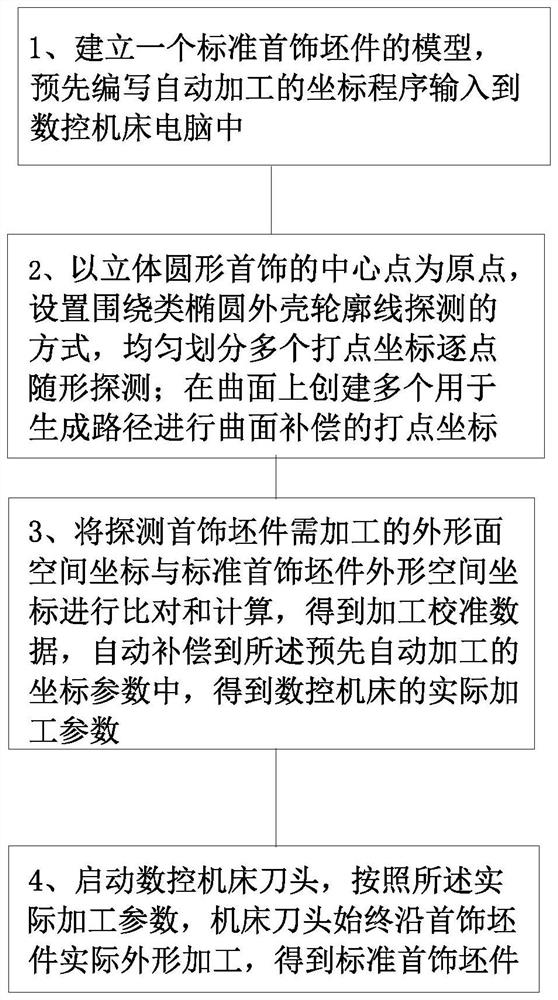

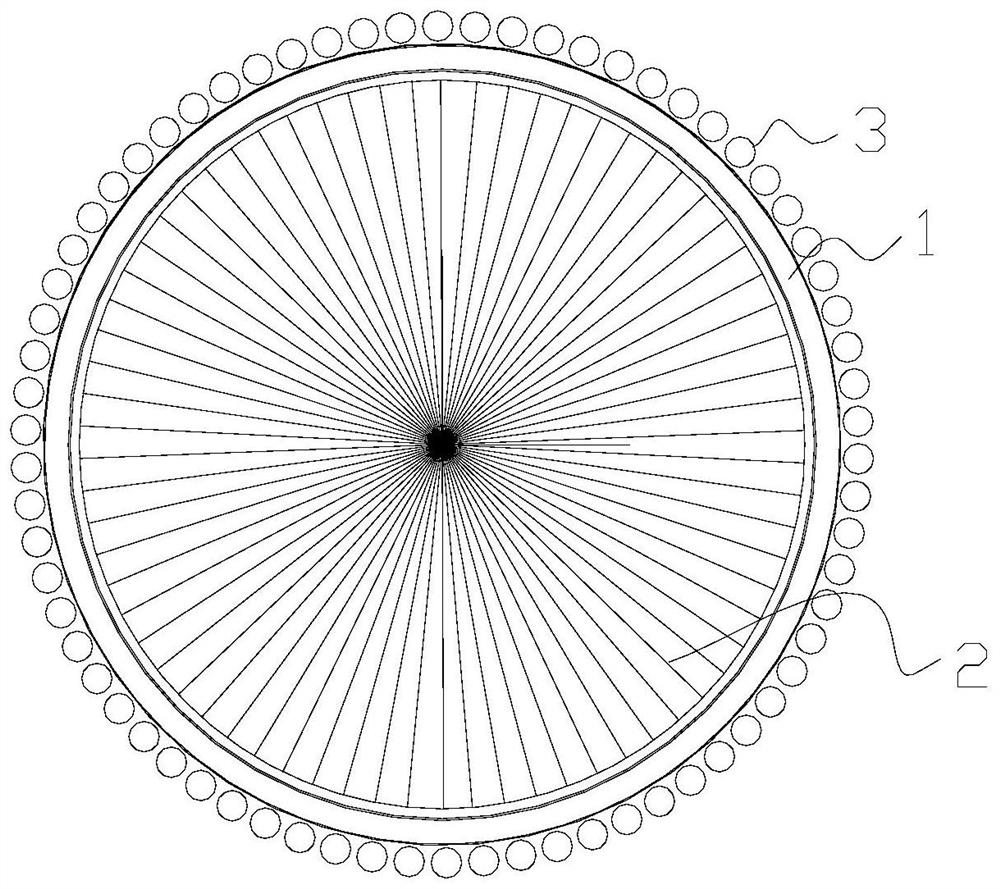

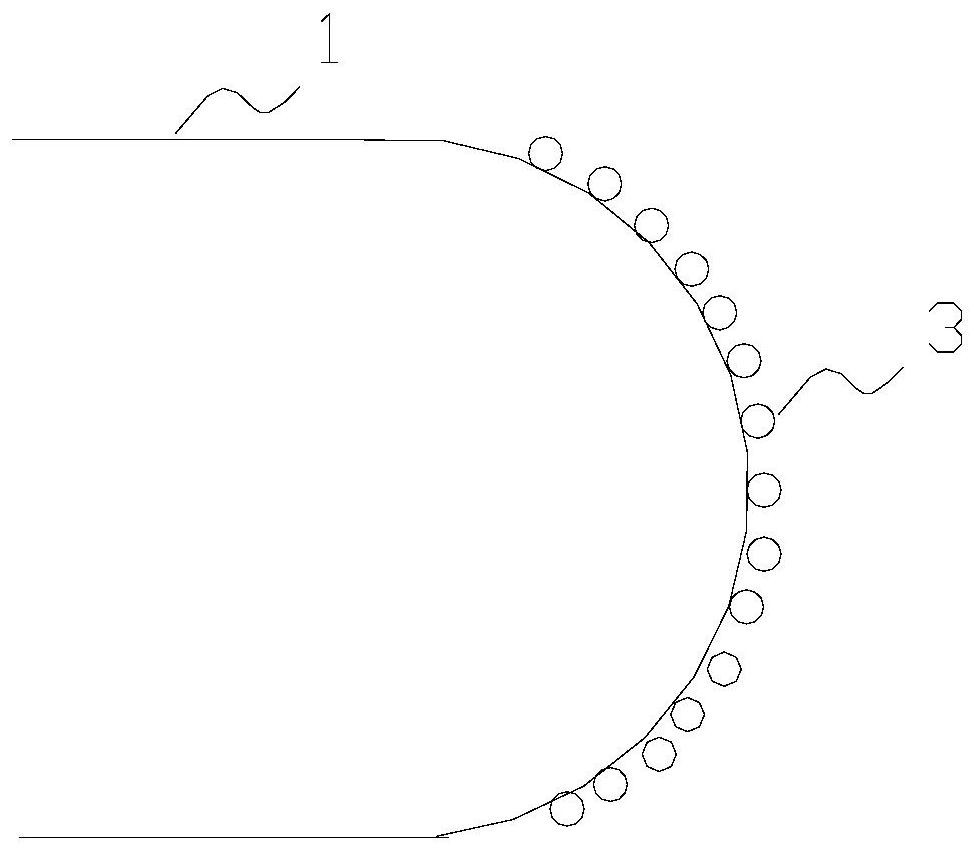

[0026]Next, the technical solutions in the present embodiment will be described in conjunction with the drawings in the present embodiment.

[0027]At present, the CNC machine is only used to process hard metal materials such as stainless steel and cast iron, and there is no discovery to use in large quantities of industrialization in the field of jewelry processing. This is because the shape, texture, and inside and outside of the different jewelry are different. Since each jewelry crude embryo body has different thicknesses and dimensional differences. Therefore, the current jewelery processing is usually used in conjunction with simple electric grinding tools, such jewelry appearance is not bright, and the pattern is not very beautiful.

[0028]The invention improves processing technology. After thousands of development tests, it is proposed that the application of the spike-measuring machining control method in the field of jewelry processing is prequtered in advance, prequopbenes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com