Preparation method of whey tofu

A whey and tofu technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of low water retention rate and elasticity of tofu, unstable physalis water performance, flavor and nutritional damage, etc., and achieve excellent water retention rate and Flexibility, shortening the time taken, and the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

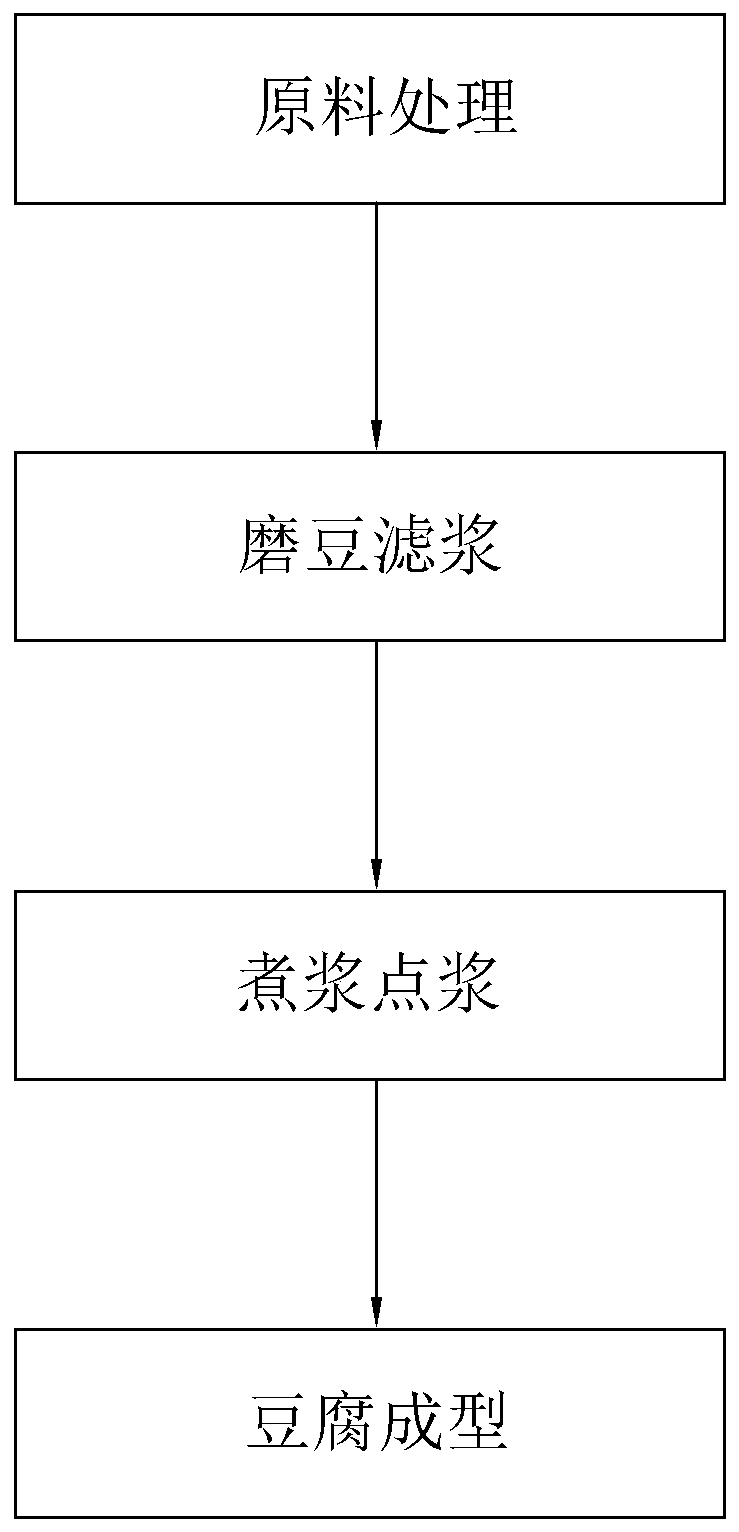

Method used

Image

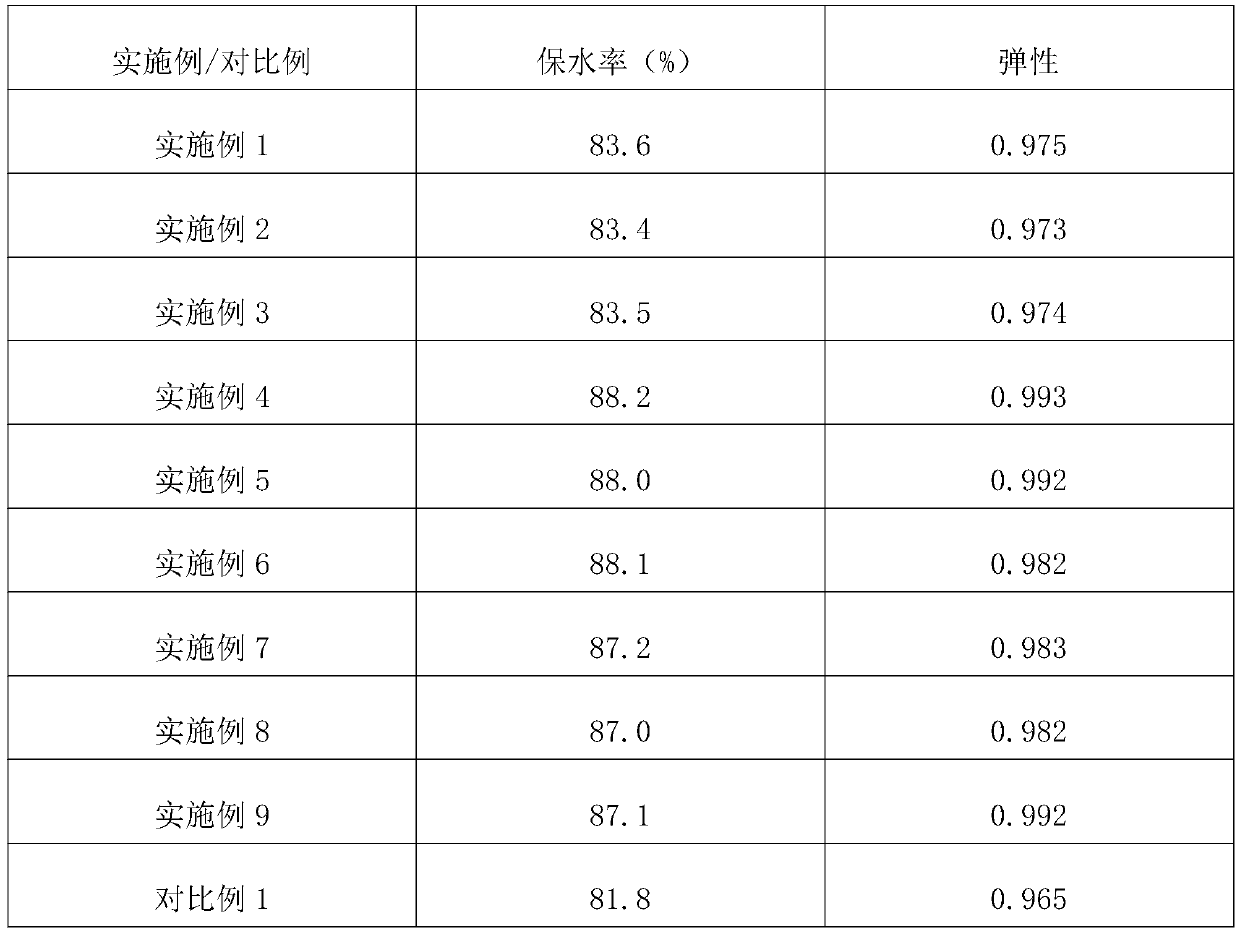

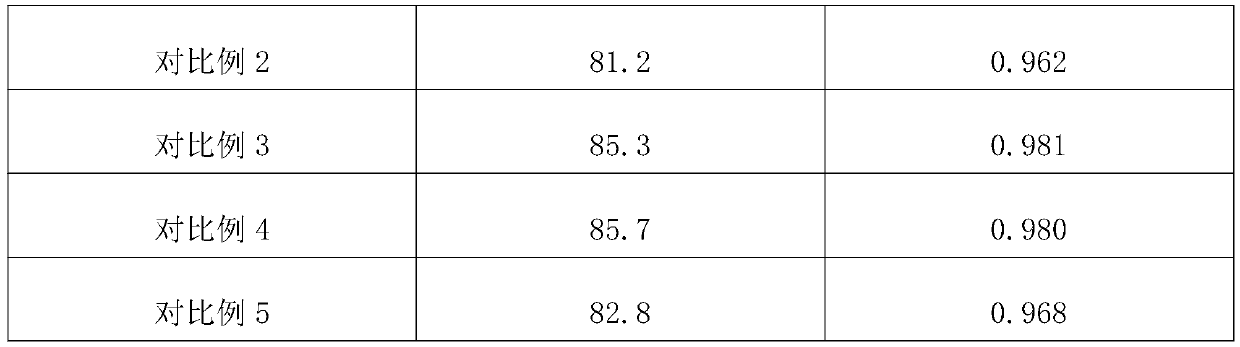

Examples

Embodiment 1

[0034] Embodiment 1: a kind of preparation method of whey tofu specifically comprises the following steps:

[0035] Step 1, raw material processing: taking soybeans as raw materials, soaking them in whey solution, the mass ratio of soybeans and whey solution is 1:3.5, standing for treatment, soaking and standing time is 5.5h;

[0036]Step 2, Grinding soybeans and filtering pulp: Take out the soaked soybeans and mix and refine them with the whey solution. The mass ratio of soybeans and whey solution mixed and refined pulp is 1:5.5, and then pass the obtained slurry through a screen After filtering, select 95 mesh screen to obtain soybean milk;

[0037] Step 3, boiling and dispensing: Pour the obtained soybean milk into a pot and boil at a temperature of 95°C for 32.5 minutes. Skim the foam during the cooking process, and then pour in milk with a pH of 3.0. 9g / L gypsum solution prepared by mixing Qinghe gypsum, stirring and mixing, the stirring speed is 150rpm, the stirring tim...

Embodiment 2

[0040] Embodiment 2: a kind of preparation method of whey tofu, differs from embodiment 1 in that, specifically comprises the following steps:

[0041] Step 1, raw material processing: taking soybeans as raw materials, soaking them in whey solution, the mass ratio of soybeans and whey solution is 1:3, standing for processing, soaking and standing for 5 hours;

[0042] Step 2, Grinding soybeans and filtering pulp: Take out the soaked soybeans, and mix and refine them with whey solution. The mass ratio of mixing soybeans and whey solution is 1:5, and then pass the obtained slurry through a screen After filtering, select 90 mesh screen mesh to obtain soybean milk;

[0043] Step 3, boiling and dispensing: Pour the obtained soybean milk into a pot and boil at a temperature of 90°C for 40 minutes. Skim the foam during the cooking process, and then add whey and whey with a pH of 3.0. The 8g / L gypsum solution prepared by gypsum is stirred and mixed, the stirring speed is 140rpm, the ...

Embodiment 3

[0045] Embodiment 3: A kind of preparation method of whey tofu, differs from embodiment 1 in that, specifically comprises the following steps:

[0046] Step 1, raw material processing: taking soybeans as raw materials, soaking them in whey solution, the mass ratio of soybeans and whey solution is 1:4, standing for processing, soaking and standing for 6 hours;

[0047] Step 2, Grinding and filtering soybeans: Take out the soaked soybeans, and mix and refine them with the whey solution. The mass ratio of soybeans and whey solution is 1:6, and then pass the obtained slurry through a screen After filtering, the sieve is selected to be 100 mesh to obtain soybean milk;

[0048] Step 3, boiling and dispensing: Pour the obtained soybean milk into a pot and boil at a temperature of 100°C for 25 minutes. During the cooking process, the foam is skimmed off, and then the whey and whey with a pH of 3.0 are added The 10g / L gypsum solution prepared by gypsum is stirred and mixed, the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com