Special powder for bean products with traditional taste and products of special powder

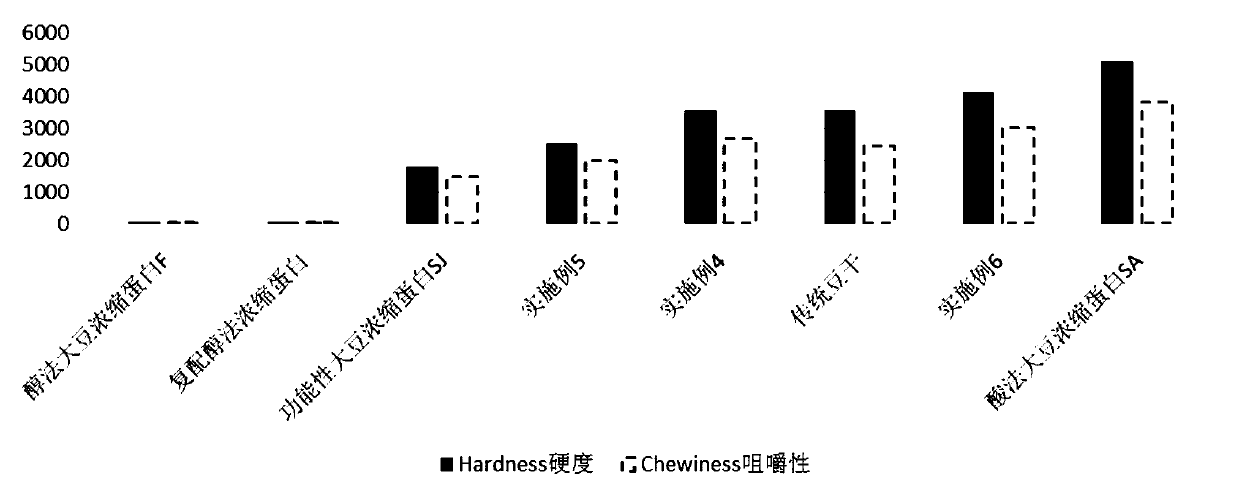

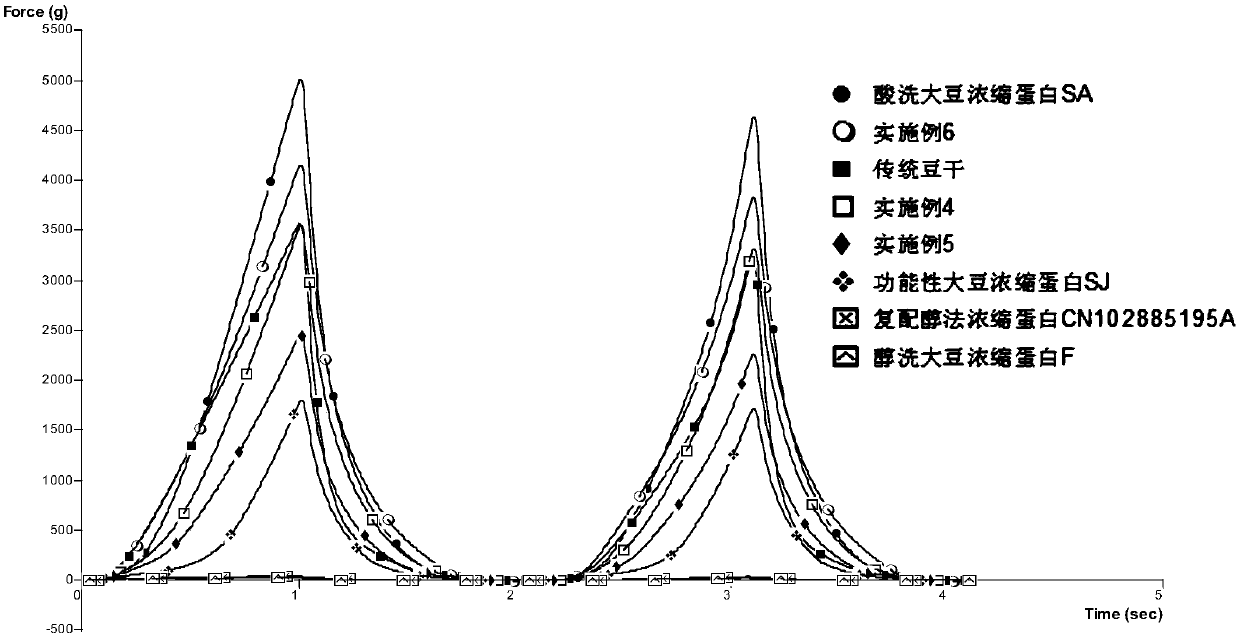

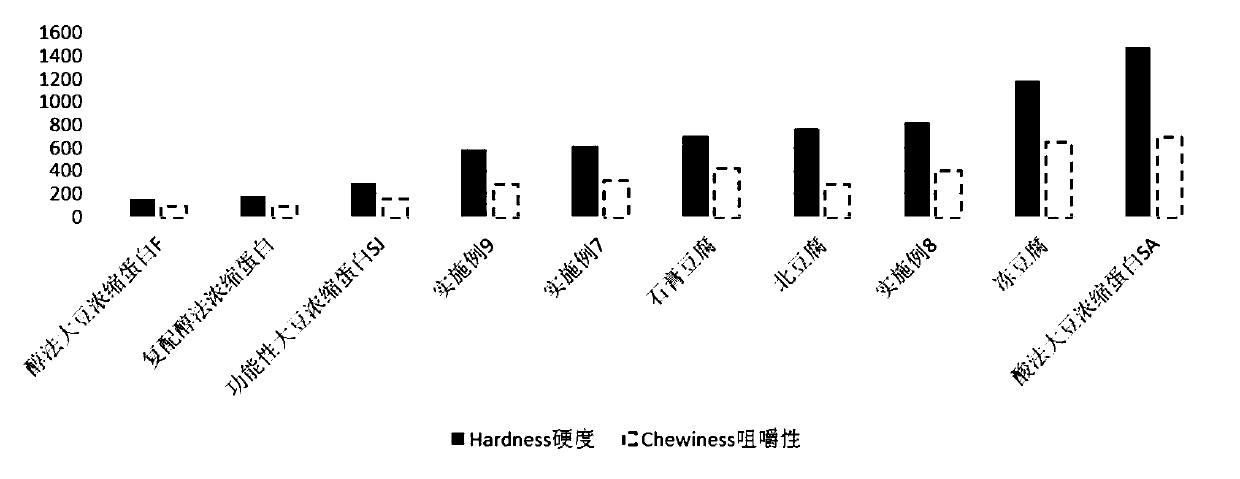

A technology for special powder and bean products, applied in the field of special powder for traditional taste bean products and the bean products prepared therefrom, can solve the problems of great differences in hardness, chewiness and elastic taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Novel protein concentrate preparation

[0097] 1) Evenly disperse alcohol-processed soybean protein concentrate in water at a mass concentration of 10% under continuous stirring conditions, add hydrochloric acid with a concentration of 5mol / L and pump it into the acid sinking tank, the pH of the liquid at the outlet of the acid sinking tank is 4.4, and centrifuge through decanter Machine centrifuged at 3000rpm to obtain solid phase curd;

[0098] 2) In the water in the curd tank, adjust the solid mass content to 5% under continuous stirring conditions, pump it into the neutralization tank and add alkali to pH6.8;

[0099] 3) Sterilize by high-temperature instantaneous heating at a temperature of 121° C. for 60 seconds, flash negative pressure of -0.07 MPa, homogenize under a high pressure of 150 bar, and then spray-dry to obtain a novel soybean protein concentrate.

[0100] The physicochemical and functional properties of the novel soybean protein concentrate prepared ...

Embodiment 2

[0103] Novel protein concentrate preparation

[0104] 1) Evenly disperse the alcohol-processed soybean protein concentrate in water at a mass concentration of 15% under continuous stirring conditions, add 12mol / L sulfuric acid and pump it into the acid sinking tank, the pH of the liquid at the outlet of the acid sinking tank is 4.6, and centrifuge through decanter Machine centrifuged at 5000rpm to obtain solid phase curd;

[0105] 2) Add water to the curd tank, adjust the solid mass content to 17% under continuous stirring conditions, pump into the neutralization tank and add alkali to pH7.8;

[0106] 3) Sterilize by high-temperature instantaneous heating at a temperature of 140° C. for 5 seconds, flash negative pressure of -0.09 MPa, homogenize under a high pressure of 300 bar, and then spray dry to obtain a novel soybean protein concentrate.

[0107] The physicochemical and functional properties of the novel soybean protein concentrate prepared through the above steps are a...

Embodiment 3

[0110] Novel protein concentrate preparation

[0111] 1) Evenly disperse alcohol-processed soybean protein concentrate in water at a mass concentration of 13% under continuous stirring conditions, add lactic acid with a concentration of 6mol / L and pump it into the acid sinking tank, the pH of the liquid at the outlet of the acid sinking tank is 4.6, and centrifuge in a decanter The machine centrifuges at 4000rpm to obtain solid phase curd;

[0112] 2) Add water to the curd tank, adjust the solid mass content to 13% under continuous stirring conditions, pump into the neutralization tank and add alkali to pH7.5;

[0113] 3) Sterilize by high-temperature instantaneous heating at a temperature of 137° C. for 30 seconds, flash negative pressure of -0.08 MPa, spray-dry after 200 bar high-pressure homogenization to obtain a novel soybean protein concentrate.

[0114] The physicochemical and functional properties of the novel soybean protein concentrate prepared through the above ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com