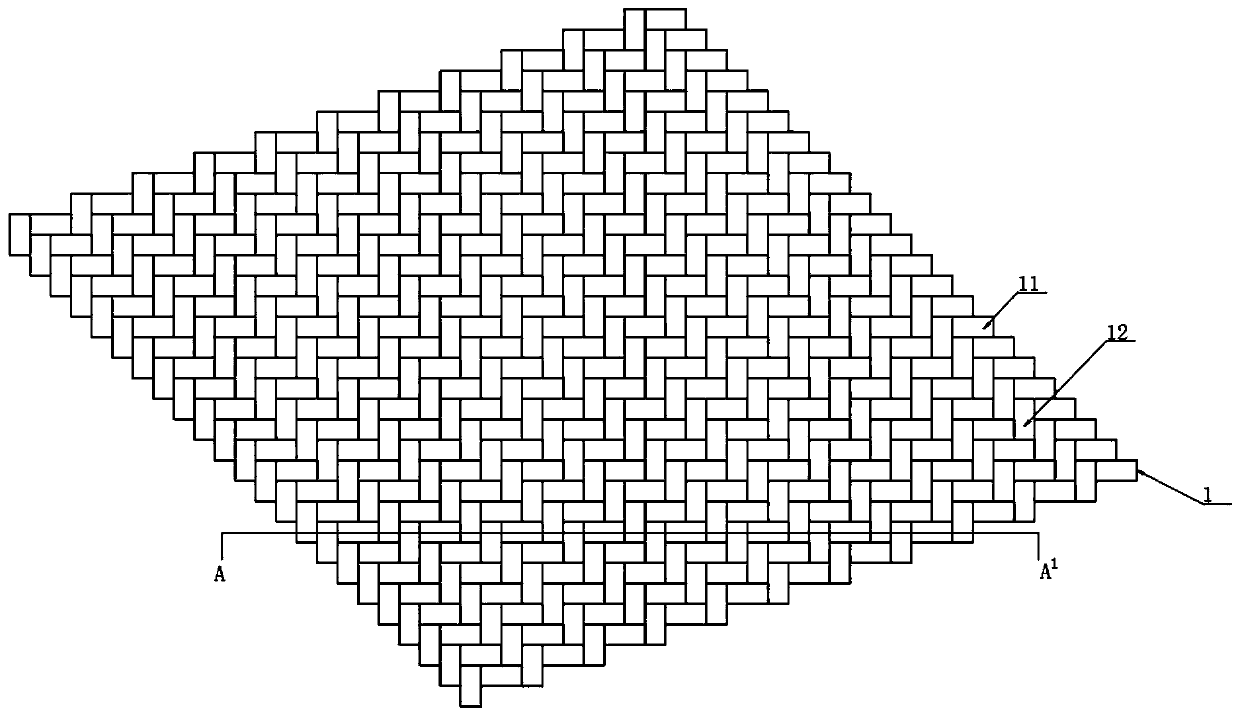

Anti-pilling knitted fabric and preparation method thereof

An anti-pilling technology for knitted fabrics, applied in fabric surface trimming, textile material processing, textiles, etc., can solve the problems of short anti-pilling time, easy deformation and damage, beautiful appearance of knitted fabrics and health effects, etc., to achieve reduction The effects of fabric surface imperfections, ensuring toughness and strength, and reducing the possibility of fiber breakage and pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

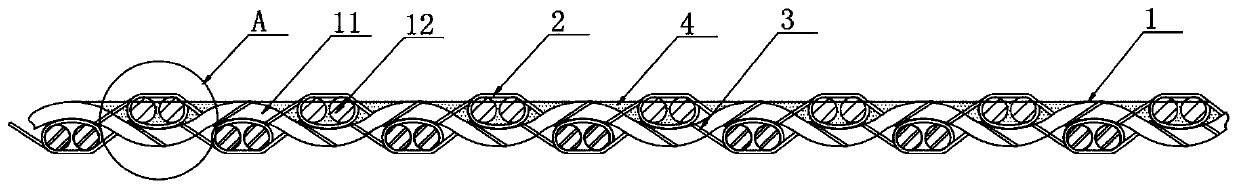

[0041] The invention provides a preparation method of anti-pilling knitted fabric, the specific operation steps are:

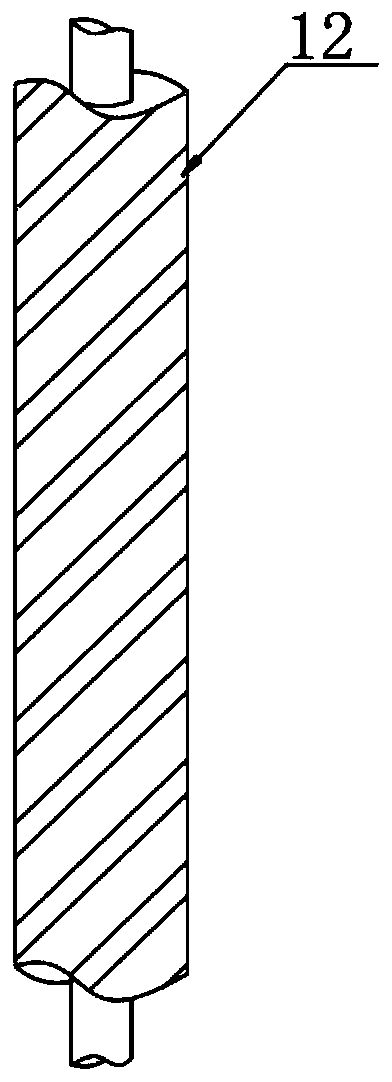

[0042] Step 1: Prepare blended yarn, take polyester fiber, mohair fiber, milk staple fiber and frame cotton in proportion, take polyester fiber as the main axis, evenly weave mohair fiber, milk staple fiber and frame cotton on polyester fiber the outside, made into a blended yarn and wound;

[0043] The added volume ratio of polyester fiber, mohair fiber, milk short fiber and frame cotton in the blended yarn is set to 2:1:1:1;

[0044] Step 2: Rough treatment of blended yarn, as follows:

[0045] S1: Composite polyvinyl acetate, softener and ethanol in a ratio of 2:1:10 by volume to form a fiber treatment agent, set aside;

[0046] The softening agent is set to cetyltrimethylammonium bromide;

[0047] S2: Use an empty shaft to wind the blended yarn and change the shaft, and slightly twist the blended yarn to be prepared during the process;

[0048] S3: Ten...

Embodiment 2

[0058] The invention provides a preparation method of anti-pilling knitted fabric, the specific operation steps are:

[0059] Step 1: Prepare blended yarn, take polyester fiber, mohair fiber, milk staple fiber and frame cotton in proportion, take polyester fiber as the main axis, evenly weave mohair fiber, milk staple fiber and frame cotton on polyester fiber the outside, made into a blended yarn and wound;

[0060] The added volume ratio of polyester fiber, mohair fiber, milk short fiber and frame cotton in the blended yarn is set to 2.5:1.5:1:1;

[0061] Step 2: Rough treatment of blended yarn, as follows:

[0062] S1: Composite polyvinyl acetate, softener and ethanol in a ratio of 3:2:10 by volume to form a fiber treatment agent, set aside;

[0063] The softening agent is set to cetyltrimethylammonium bromide;

[0064] S2: Use an empty shaft to wind the blended yarn and change the shaft, and slightly twist the blended yarn to be prepared during the process;

[0065] S3:...

Embodiment 3

[0075] The invention provides a preparation method of anti-pilling knitted fabric, the specific operation steps are:

[0076] Step 1: Prepare blended yarn, take polyester fiber, mohair fiber, milk staple fiber and frame cotton in proportion, take polyester fiber as the main axis, evenly weave mohair fiber, milk staple fiber and frame cotton on polyester fiber the outside, made into a blended yarn and wound;

[0077] The added volume ratio of polyester fiber, mohair fiber, milk short fiber and frame cotton in the blended yarn is set to 3:2:1:1;

[0078] Step 2: Rough treatment of blended yarn, as follows:

[0079] S1: Composite polyvinyl acetate, softener and ethanol in a ratio of 4:3:10 by volume to form a fiber treatment agent, set aside;

[0080] The softening agent is set to cetyltrimethylammonium bromide;

[0081] S2: Use an empty shaft to wind the blended yarn and change the shaft, and slightly twist the blended yarn to be prepared during the process;

[0082] S3: Ten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com