PTA refining wastewater resource recycling device and method based on electrodialysis

A technology for refining wastewater and electrodialysis, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. It can solve the problem of not being able to fully realize the effective recovery and utilization of benzene carboxylic acid resources, and reduce steam consumption and treatment. The effect of load and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

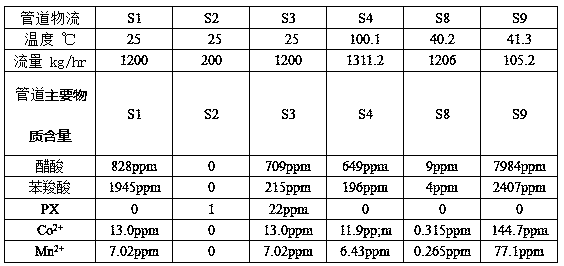

[0035] PTA refined wastewater is fed from the upper part of the extraction tower 1 with a flow rate of 1200 kg / hr, and the extractant is fed from the lower part of the extraction tower with 200 kg / hr of p-xylene. The number of theoretical plates of the extraction tower 1 is 8. After extraction, the wastewater discharged from the bottom of the extraction tower contains 215ppm of benzenecarboxylic acid, 0.0788% of acetic acid, 22ppm of p-xylene, Co 2+ Ion 13.0ppm, Mn 2+ Ion 7.02ppm. The waste water coming out from the bottom of the extraction tower 1 enters the stripping tower 3 whose number of theoretical plates is 28 from the top, and its feeding port is at the sixth block position from top to bottom. The steam of 3kg pressure is passed into the tower still of stripping tower 3, and its mass flow rate is 112kg / hr.

[0036] The material extracted from the top of the stripper 3 contains a small amount of water vapor of p-xylene, and after passing through the condenser 4, it b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com