Method for preparing antimony sulfide film through low-temperature plasma vulcanization

A low-temperature plasma, antimony sulfide technology, applied in antimony sulfide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of loose structure and composition deviation, increase of ambient temperature, increase of thermal motion of solid sulfur source, etc. Large size, flat structure, and the effect of low temperature growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

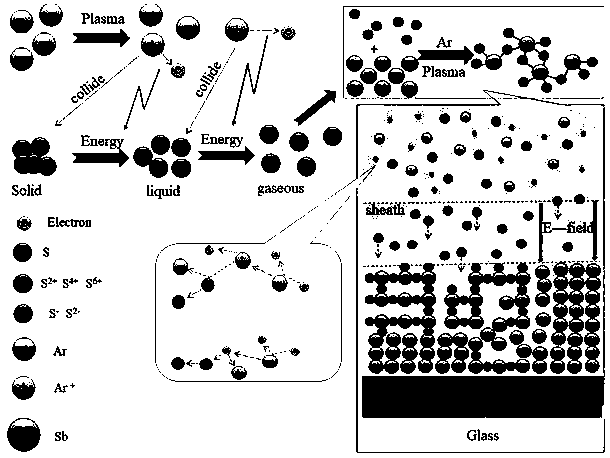

[0030] Embodiment 1: A kind of method for preparing antimony sulfide film by low-temperature plasma vulcanization, concrete steps are as follows:

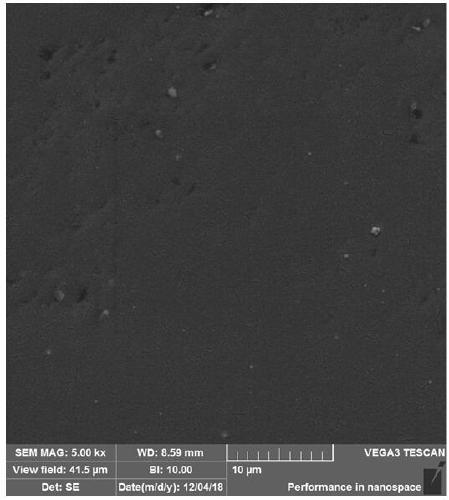

[0031] (1) Metal antimony thin films were prepared by vapor deposition method (see figure 2 ):

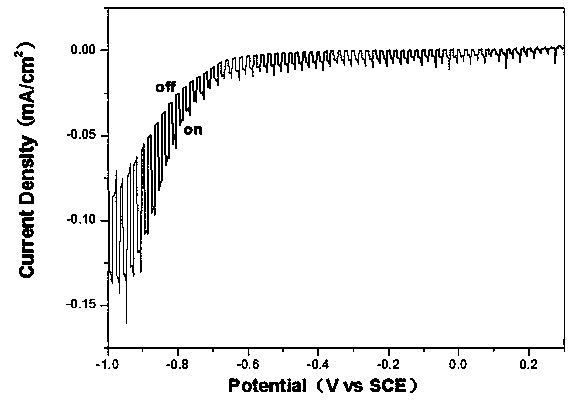

[0032] with SbCl 3 (99.99% pure) with H 2 (99.99% purity) as raw material, deposit pure antimony film on soda-lime glass substrate: the deposition process is carried out in a quartz tube furnace, the deposition furnace is heated by resistance wire, and the power of the deposition system is controlled and adjusted by a thyristor voltage regulator , using Ni-Ni-Si thermocouple to measure the substrate temperature, using needle valve and flowmeter to control the SbCl 3 and H 2 The gas flow rate, the deposition temperature is about 400°C, and the mixed gas ratio is n(SbCl 3 ):n(H 2 )=1:2, the gas outlet of the deposition furnace is fed into saturated KOH solution and then ignited or emptied into the atmosphere; from the surface SEM i...

Embodiment 2

[0035] Embodiment 2: a kind of method for preparing antimony sulfide film by low-temperature plasma vulcanization, concrete steps are as follows:

[0036] (1) Prepare antimony oxide film by spray pyrolysis method: accurately weigh 10 g of analytically pure Sb(NO 3 ) 3 Dissolve in 250 ml dilute HNO with a mass fraction of 5% 3 In the solution, under the protective atmosphere of argon, the Sb(NO 3 ) 3 The solution is atomized into aerosol droplets, and a flat electric furnace with Mo conductive glass is placed in the system. The temperature of the flat electric furnace is 400 ° C. The antimony oxide film is deposited on Mo On the conductive glass, the tail gas is discharged after being neutralized by the alkali solution in the absorption bottle; the deposited antimony oxide film can be directly used as the precursor of the antimony sulfide film prepared by low-temperature plasma vulcanization; 2 Metal antimony film can be obtained by reduction under atmosphere for 30 minutes; ...

Embodiment 3

[0043] Embodiment 3: A kind of method for preparing antimony sulfide film by low-temperature plasma vulcanization, concrete steps are as follows:

[0044] (1) Preparation of antimony hydroxide thin film by chemical bath deposition method:

[0045] Antimony hydroxide film material is prepared by chemical bath deposition. Take 2.8501 grams of antimony trichloride solid raw material, 5 milliliters of ammonia water, and 25 milliliters of triethanolamine in a small beaker. After the dissolution and complexation are complete, pour it into a 250 milliliter volumetric flask Constant volume, the antimony concentration of the obtained solution is 0.05mol / L, adjust the pH value of the solution to 7.2 with hydrochloric acid or sodium hydroxide, put the solution in a 500 mL beaker, and put the washed and dried SnO plated in the beaker. 2 Glass (with a square resistance of 20Ω) was used as the experimental substrate material; the beaker was placed in a water bath at a temperature of 70°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Band gap width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com