Method for preparing multifunctional protective clothing for mine

A protective clothing, multi-functional technology, applied in the fields of biochemical fiber treatment, textile and papermaking, fiber treatment, etc., can solve problems such as unfavorable staff health, easy to breed bacteria, etc., and achieve the effect of not easy to precipitate and improve washability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

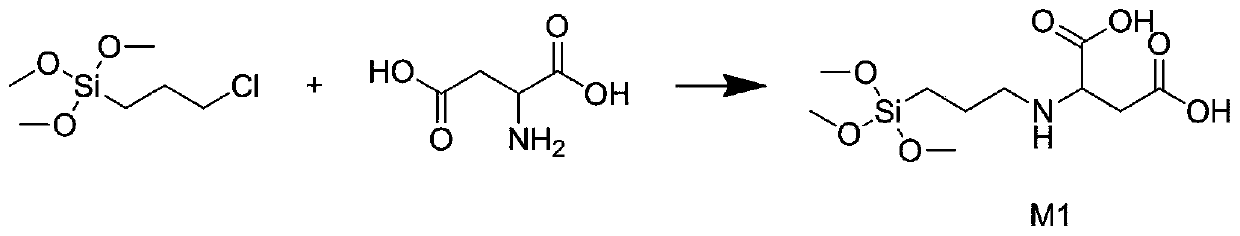

[0029] see figure 1 As shown, the preparation of the modified cross-linking agent

[0030] In the reaction flask, add 100ml of solvent pyridine, weigh 10mmol of L-aspartic acid, stir to dissolve it completely, then add 11-12mmol of γ-chloropropyltrimethoxysilane drop by drop, after stirring and mixing, the reaction flask Put it into a microwave chemical reactor, heat the reaction by microwave at a power of 560W and a temperature of 110-115°C for 5-7h. After the reaction is over, cool it down to room temperature naturally, and remove the solvent by rotary evaporation. The crude product is recrystallized with acetone and dried. After that, the modified cross-linking agent M1 is obtained;

[0031] After detection, the mass spectrum of the raw material intermediate M1 is: HRMS m / z (ESI + )calcd for C 10 h 21 NO 7 Si([M] + ), 295.11, found 295.3602.

Embodiment 2

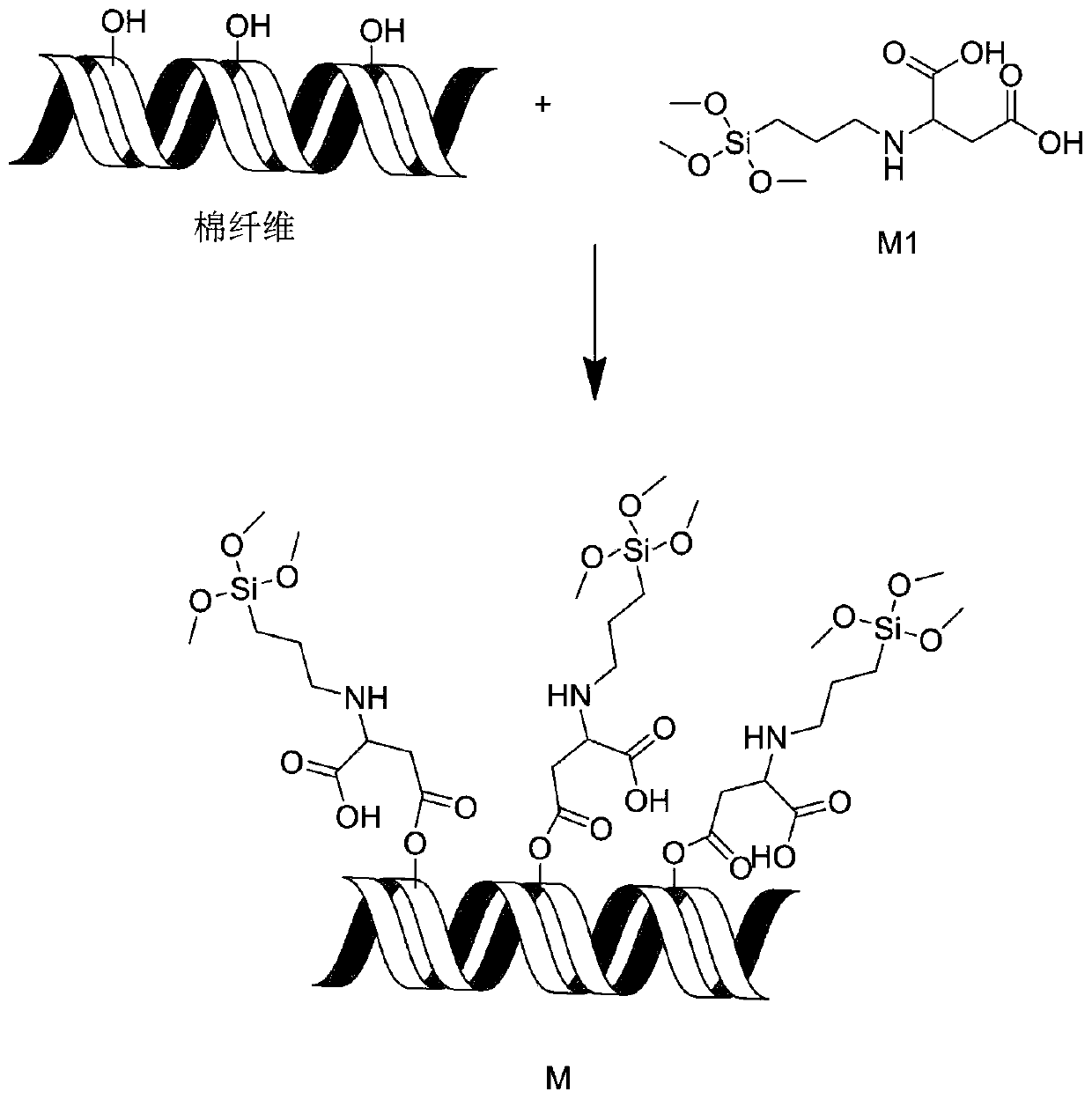

[0033] see figure 2 Shown, the second step, the preparation of modified cotton fiber

[0034] Preparation of modified solution: Weigh the modified cross-linking agent M1 and sodium dihydrogen phosphate prepared in the first step in deionized water, and mix the modified cross-linking agent M1 with a concentration of 50g / L and 65g / L of sodium dihydrogen phosphate The aqueous solution is the modified solution;

[0035] The pretreatment of cotton fibers is as follows: immerse 10 g of cotton fibers in 200 ml of 10% sodium hydroxide aqueous solution, stir for 30 min, remove the cotton fibers and wash off the lye with deionized water, and dry at room temperature.

[0036] Immerse the pretreated cotton fiber in the modified solution, the bath ratio of cotton fiber and modified solution is 1g:30ml; then place it in a water bath magnetic stirring pot, the temperature of the water bath is 70°C, heat preservation and stirring for 11h, take out Cotton fibers were placed in an oven and d...

Embodiment 3

[0039] Preparation of antibacterial finishing solution:

[0040] In a beaker, add 50ml of deionized water, weigh 15mg of sodium citrate and add it, dissolve completely, add 2mg of silver nitrate, stir and mix for 30min, then add 2ml of 10mmol / L NaBH dropwise 4 After adding the aqueous solution, adjust the pH of the solution to 12 with 10% sodium hydroxide aqueous solution, continue to stir for 5 minutes, age for 3 hours, centrifuge, wash with deionized water, and vacuum dry to obtain the silver finishing agent, and dissolve the silver finishing agent In distilled water, prepare an antibacterial finishing solution with a concentration of 20 mg / L for subsequent use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com