Antibacterial hemp fiber and fabric

An antibacterial hemp and hemp fiber technology, applied in the direction of artificial filaments, textiles, and yarns made of cellulose derivatives, can solve the problems of bacteria and fungi and other microorganisms, such as growth, reproduction, human health threats, humidity, heat and other problems , to achieve the effect of efficient antibacterial and mildew resistance, easy operation and broad antibacterial spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

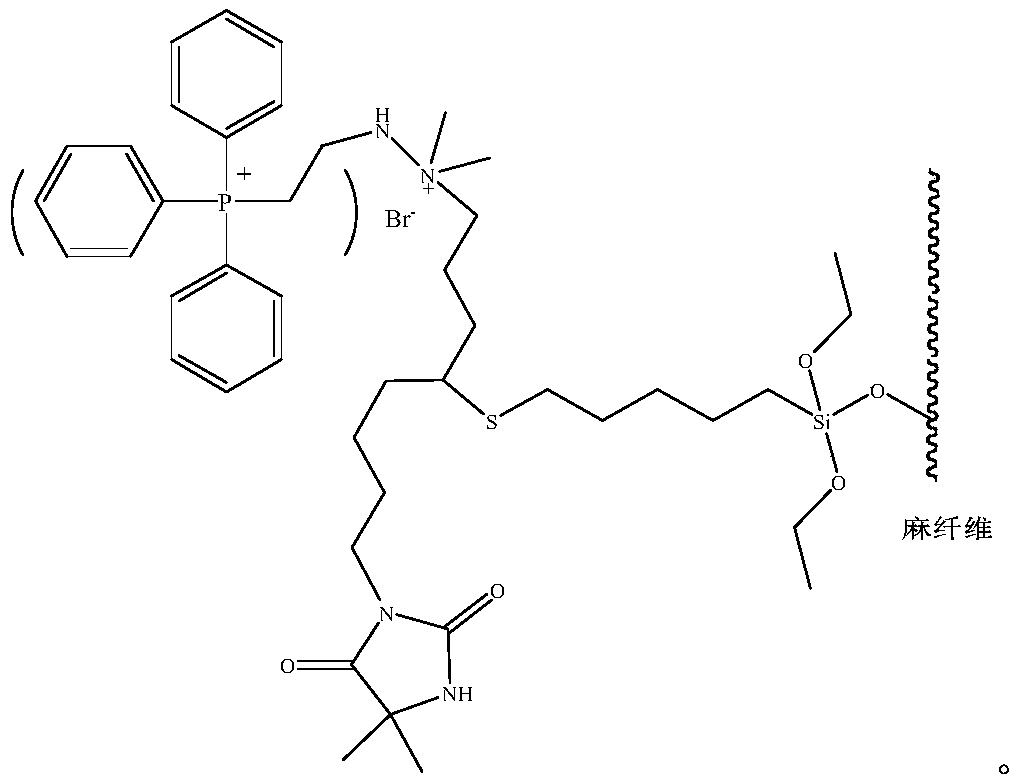

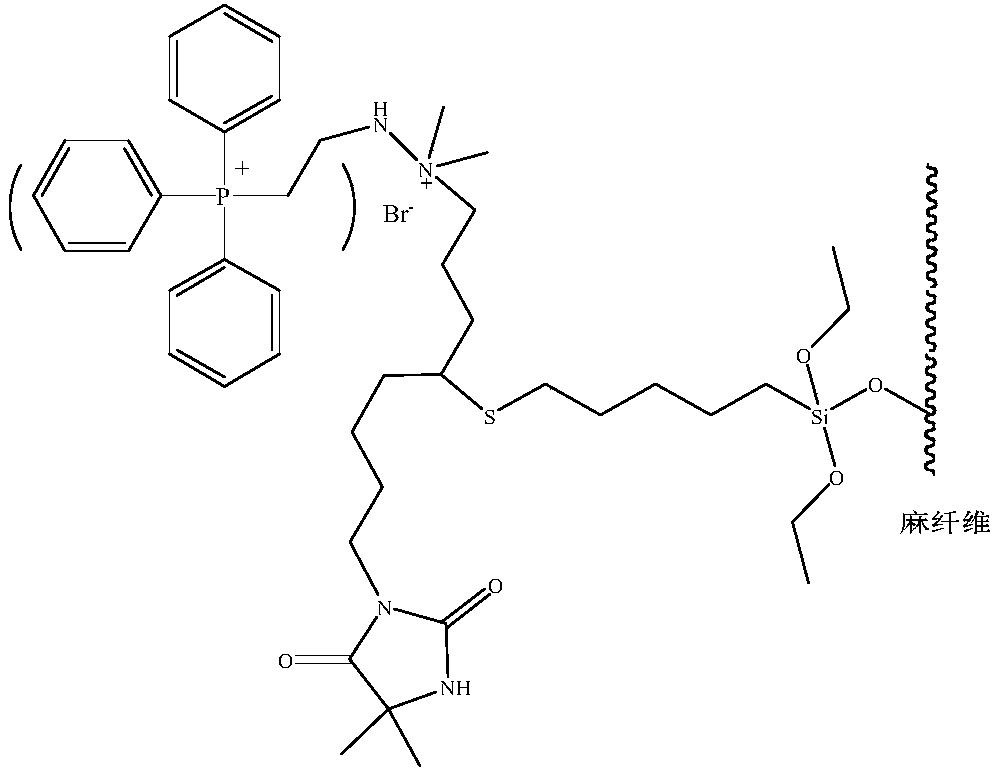

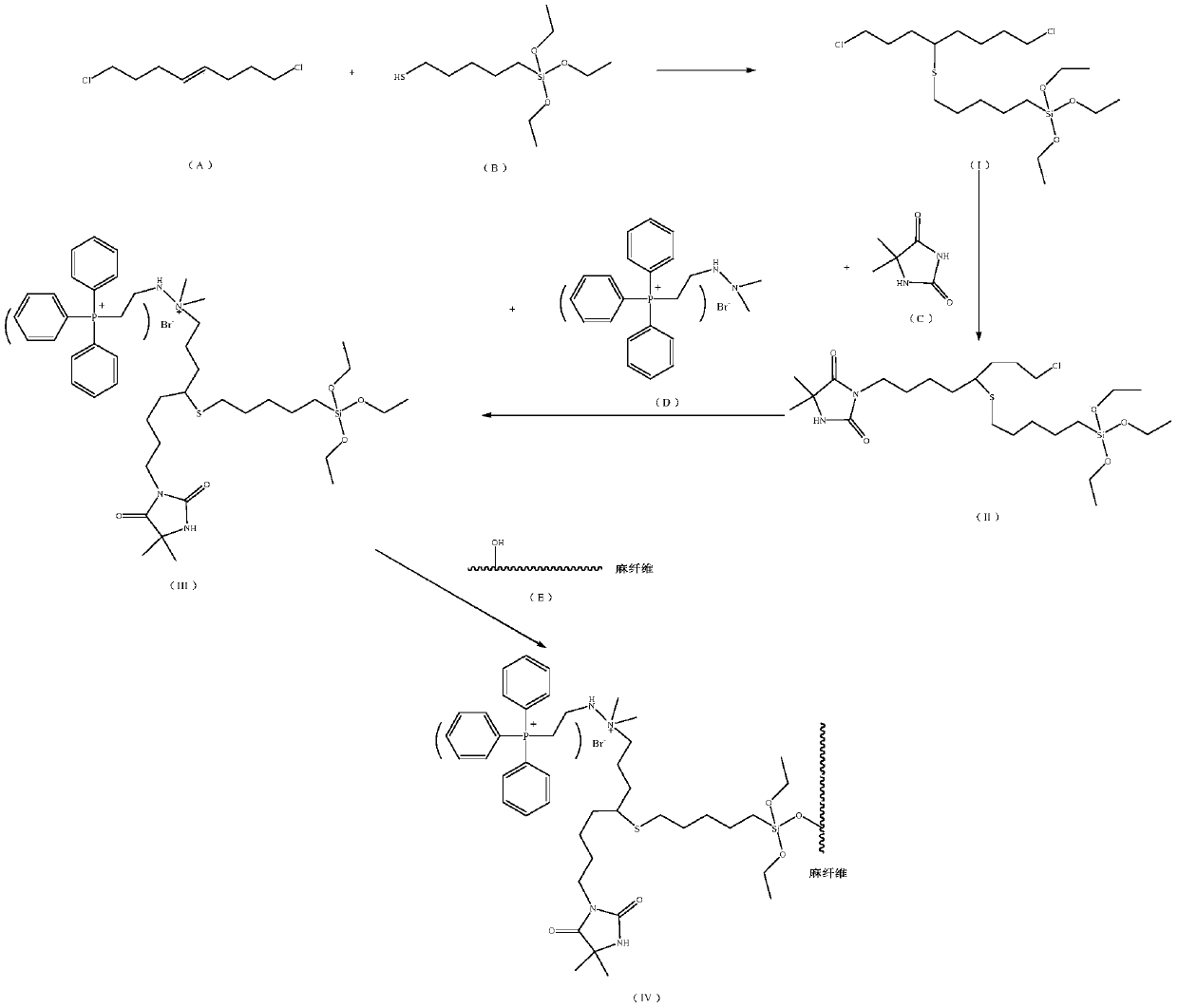

[0038] Antibacterial hemp fiber preparation steps are as follows:

[0039] Step (1) Dissolve 1mol 1,8-dichloro-4-octene (A), 0.9-1mol mercaptosiloxane (B) in 50mol N,N-dimethylformamide, add 1wt% light Initiator 1173 was placed in a UV light curing machine, irradiated for 3 minutes, taken out, and distilled under reduced pressure to obtain the intermediate product I (IR: 1617cm -1 :-C=C-disappeared; 3431cm -1 、2401cm -1 :-SH disappears; 1095cm -1 、800cm -1 : -Si-O- exists; 747cm -1 :-C-Cl exists).

[0040] Step (2) Add 50 mol of N,N-dimethylformamide containing 1 mol of 5,5-dimethylhydantoin (C) and 1 mol of potassium iodide dropwise into 1 mol of I, stir vigorously at 80°C for 20 hours, cool, Stand still, concentrate in vacuo, purify, and dry in vacuo to obtain intermediate product II (IR: 1095cm -1 、800cm -1 : -Si-O- exists; 747cm -1 : -C-Cl weakened; 1074cm -1 :-N-N-Existence; 1679cm -1 :-C=O exists).

[0041] Step (3) Under nitrogen protection, dissolve 1mol II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com