Energy-saving antifriction lithium-based lubricating grease and preparation method thereof

A lithium-based lubricating grease and base oil technology, applied in the field of energy-saving and anti-friction lithium-based lubricating grease and its preparation, can solve the problems of difficult analysis and discovery of the surface of friction pairs, equipment damage, economic loss, etc., achieve excellent extreme pressure performance, improve Wear condition, the effect of improving anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

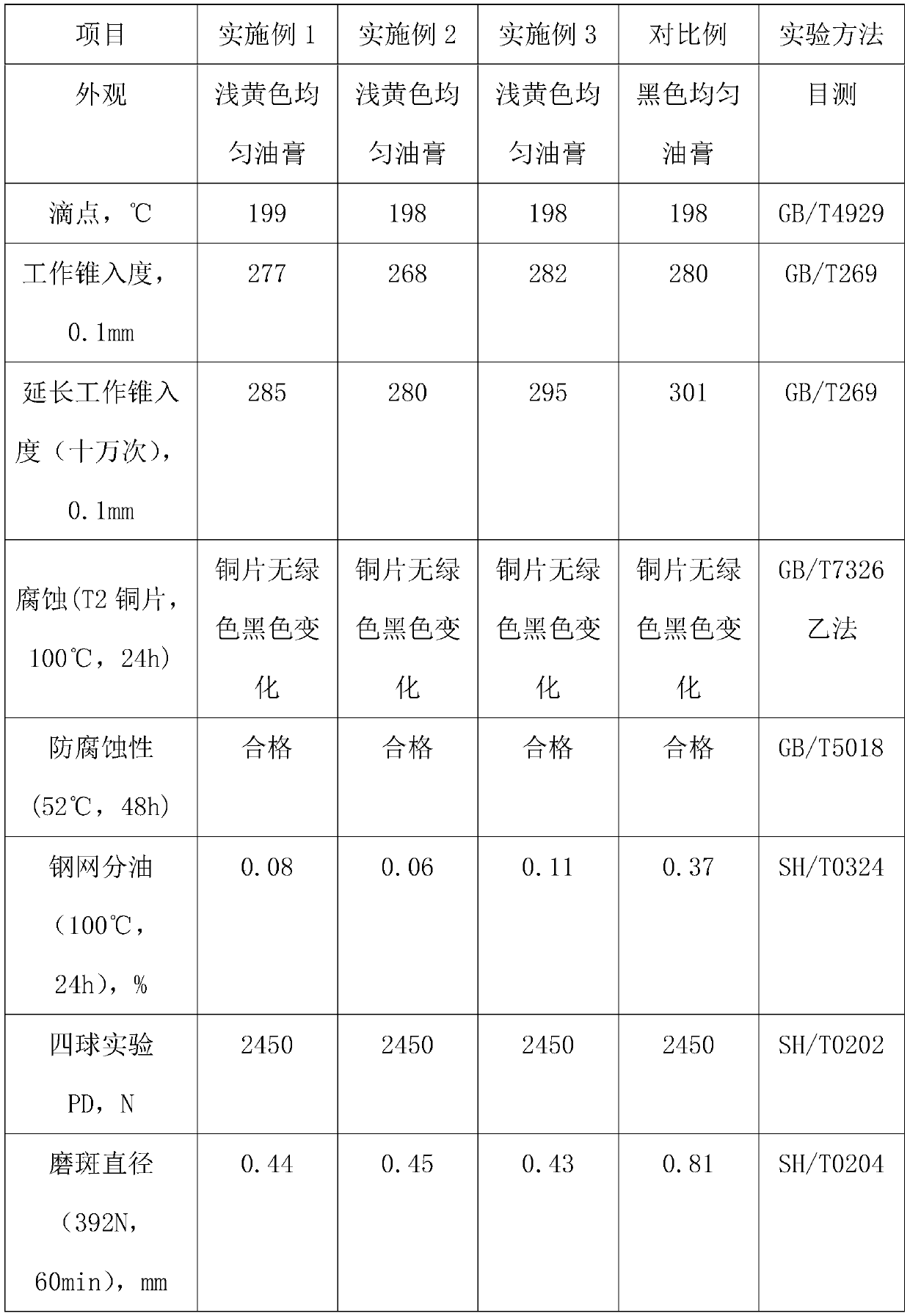

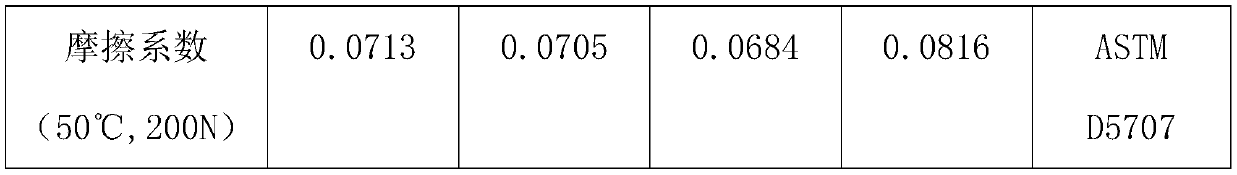

[0028] Embodiment 1: a kind of energy-saving anti-friction lithium-based grease, comprising the following components by weight parts:

[0029] Base oil: 86.5 parts of mineral oil with a kinematic viscosity of 120cst at 40°C; thickener: 9 parts of lauryl hydroxystearic acid; antioxidant: 0.2 parts of N-phenyl-α-naphthylamine; solid antifriction agent: 1.9 parts Zinc sulfide-phosphate compound and 0.9 parts of bismuth sulfide, 2.8 parts in total; rust inhibitor: 0.2 parts of benzotriazole; lithium hydroxide: 1.3 parts of lithium hydroxide monohydrate.

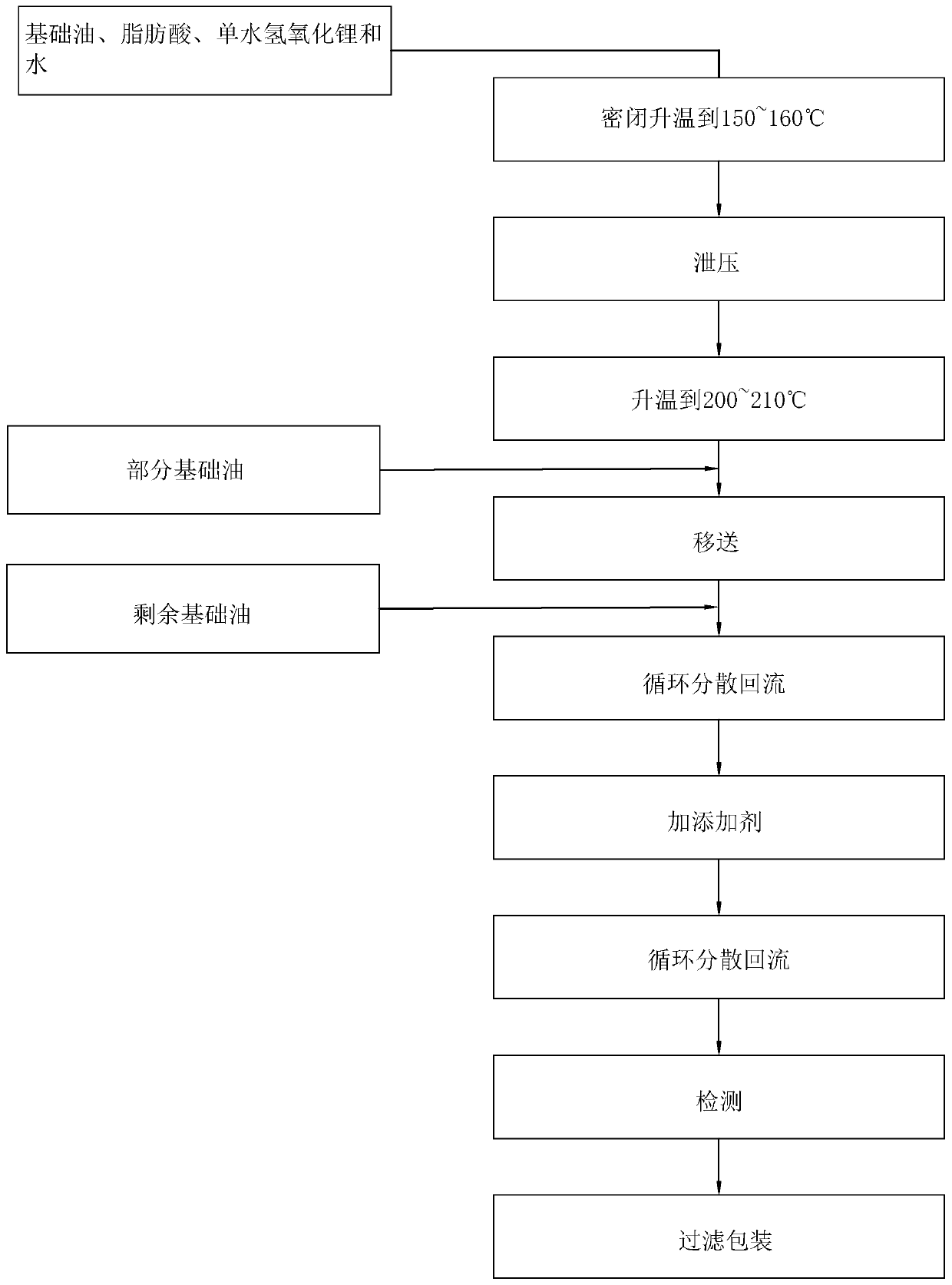

[0030] The preparation method of energy-saving anti-friction lithium base lubricating grease, such as figure 1 shown, including the following steps:

[0031] S1. Prepare raw materials according to the ratio of each component.

[0032] S2. Add 1 / 3 of mineral oil and lauryl hydroxystearic acid into the saponification tank and mix evenly, then heat the mixture to 60°C, put lithium hydroxide monohydrate and water into the saponific...

Embodiment 2

[0035] Embodiment 2: a kind of energy-saving anti-friction lithium-based grease, comprising the following components by weight parts:

[0036] Base oil: 80 parts of mineral oil with a kinematic viscosity of 140cst at 40°C; thickener: 12.4 parts of lauryl hydroxystearic acid and 2.3 parts of sebacic acid, a total of 14.6 parts; antioxidant: 0.5 part of N-phenyl-α- Naphthylamine; solid wear reducer: 2 parts of zinc sulfide-phosphate compound and 0.5 part of bismuth sulfide, 2.5 parts in total; rust inhibitor: 0.1 part of 2,6-di-tert-butyl-p-cresol and 0.1 part of thiadiazole derivative class; lithium hydroxide: 2.5 parts of lithium hydroxide monohydrate.

[0037] The preparation method of energy-saving anti-friction lithium base lubricating grease, such as figure 1 shown, including the following steps:

[0038] S1. Prepare raw materials according to the ratio of each component.

[0039] S2. Add 1 / 3 of mineral oil and lauryl hydroxystearic acid into the saponification tank and...

Embodiment 3

[0042] Embodiment 3: a kind of energy-saving friction-reducing lithium-based grease, comprising the following components in parts by weight:

[0043]Base oil: 63 parts of mineral oil with a kinematic viscosity of 120cst at 40°C and 23 parts of poly-α-olefin synthetic base oil with a kinematic viscosity of 80cst at 40°C, a total of 85 parts; thickener: 10 parts of lauryl hydroxystearic acid; Oxidizing agent: 0.3 parts of N-phenyl-α-naphthylamine; Solid antifriction agent: 2.6 parts of zinc sulfide-phosphate compound and 0.6 parts of bismuth sulfide, 2.5 parts in total; Rust inhibitor: 0.1 part of benzotriazole; Hydroxide Lithium: 1 part of lithium hydroxide monohydrate.

[0044] The preparation method of energy-saving anti-friction lithium base lubricating grease, such as figure 1 shown, including the following steps:

[0045] S1. Prepare raw materials according to the ratio of each component.

[0046] S2. Add half of the mineral oil and lauryl hydroxystearic acid into the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com