Fused salt phase change heat storage element and preparation method thereof

A technology of phase change heat storage and molten salt, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high thermal conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

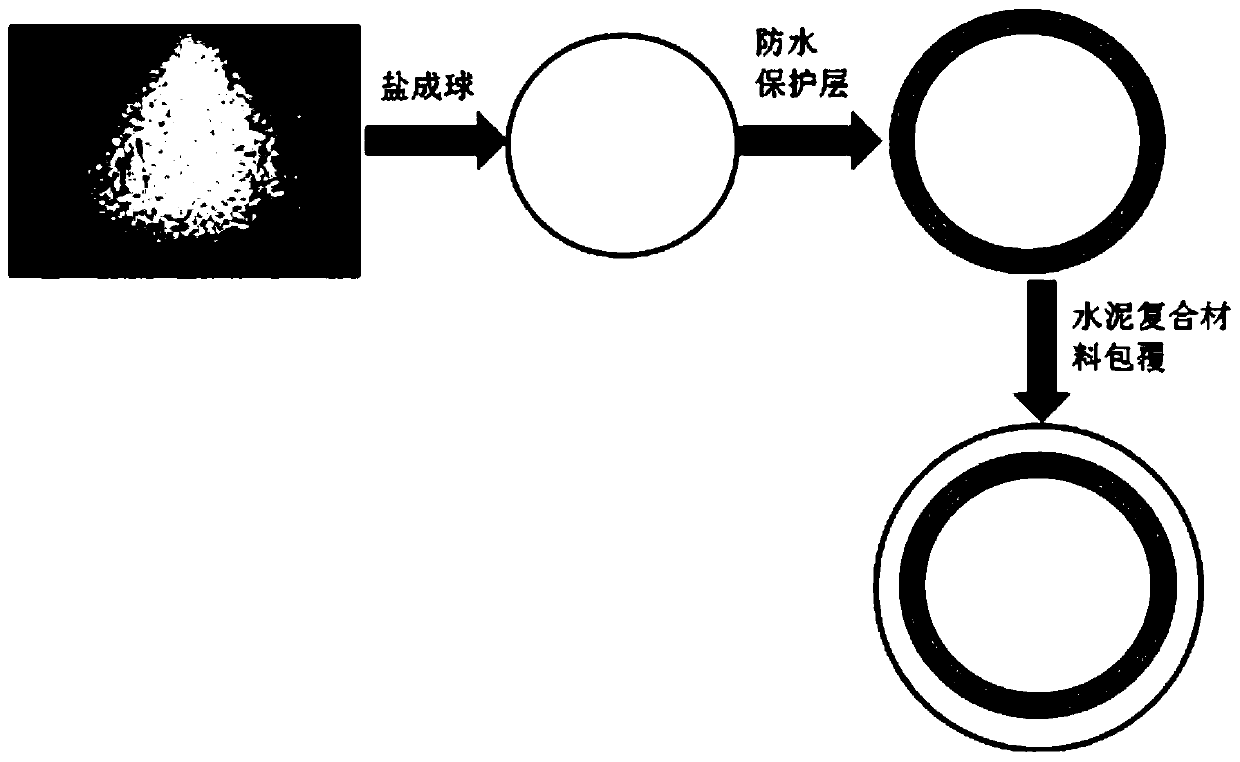

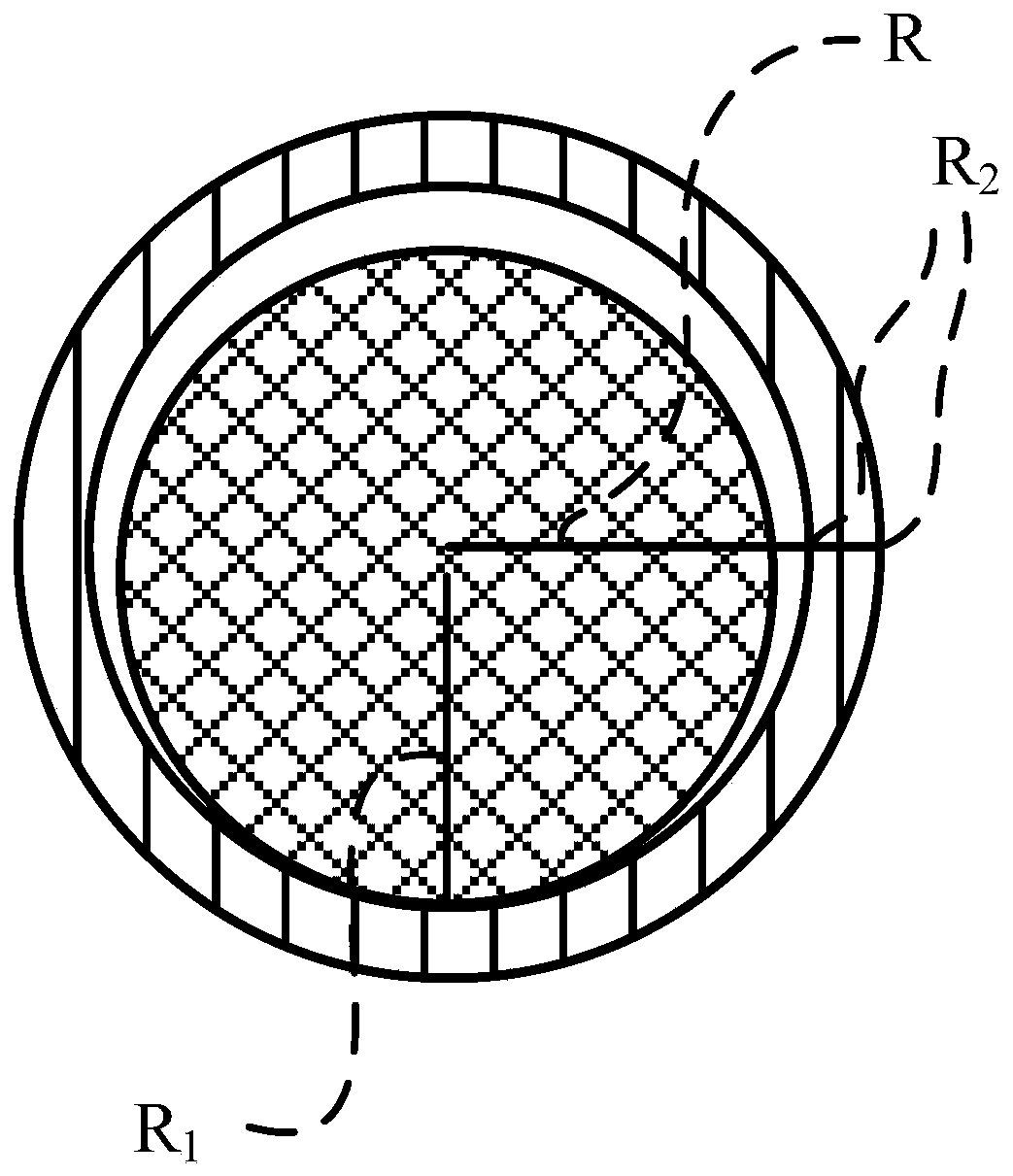

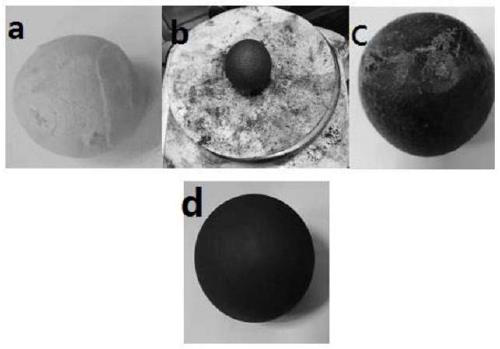

[0114] like figure 1 The schematic diagram of the preparation process is shown in:

[0115] (1) NaCl is selected as the molten salt, its melting point is 801°C, and the molten salt ball is prepared by rolling molding, and the density of the molten salt ball after molding is 1.80g / cm 3 , the radius R of the molten salt sphere 1 is 14mm.

[0116] (2) Thermoplastic polyethylene is selected as the organic material, and its viscosity in liquid state is 18000mPa·s. Roll the molten salt ball in the organic material for 10 minutes at 220°C, solidify and form at room temperature, and form a 0.2mm waterproof layer on the surface of the molten salt ball.

[0117] (3) 50 wt% graphite powder is selected to be mixed with cement, and mixed by ball milling at a rotating speed of 300r / min and ball milling time of 30min to obtain a mixed powder. Add water with a water-cement ratio (the mass ratio of water to the mixed powder of "graphite and cement") of 0.3, and mix the mixed powder and wa...

Embodiment 2

[0123] (1) Select NaCl:KCl=50.6:49.4 (molar ratio), its melting point is 657°C, and the molten salt ball is obtained by rolling molding, and the density of the molten salt ball after molding is 1.77g / cm 3 , the size of the molten salt ball is radius R 1 10mm.

[0124] (2) Thermosetting epoxy resin is selected as the organic material, which is composed of 100g E-51 epoxy resin, 50g polyurethane prepolymer and 10g diethylenetriamine, and its viscosity in liquid state is 15000mPa.s. Roll the molten salt ball in the organic material for 10 minutes at room temperature, solidify and form at 60°C, and form a 0.2mm waterproof layer on the surface of the molten salt ball.

[0125] (3) 25wt% graphite powder was selected to be mixed with cement, and mixed by ball milling at a speed of 300r / min and ball milling time of 60min to obtain a mixed powder. Add water with a water-cement ratio (the mass ratio of water to the mixed powder of "graphite and cement") of 0.6, and mix the mixed powde...

Embodiment 3

[0131] (1) Choose Li 2 CO 3 :Na 2 CO 3 :K 2 CO 3 =20:60:20 (mass ratio) is molten salt, its melting point is 550°C, and the molten salt ball is obtained by rolling molding, and the density of the molten salt ball after molding is 1.70g / cm 3 , the radius R of the molten salt sphere 1 15mm.

[0132](2) Thermoplastic polystyrene resin is selected as the organic material, and its viscosity in liquid state is 15000mPa·s. Roll the molten salt ball in the organic material for 15 minutes at 150°C, solidify and form at room temperature, and form a 0.3mm waterproof layer on the surface of the molten salt ball.

[0133] (3) 30 wt% graphite powder was selected to be mixed with cement, and mixed by ball milling at a speed of 200 r / min, and the ball milling time was 60 min, to obtain a mixed powder. Add water with a water-cement ratio (the mass ratio of water to the mixed powder of "graphite and cement") of 0.5, and mix the mixed powder and water evenly to obtain a mixed slurry.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com