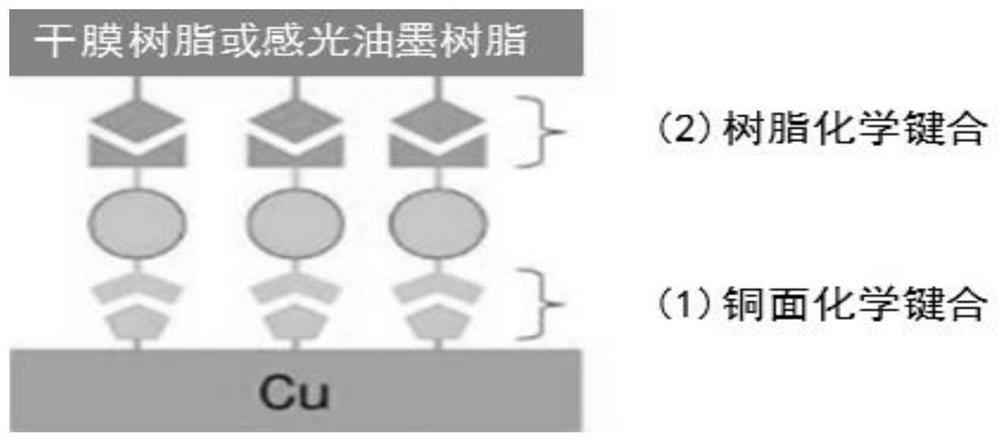

Copper surface adhesion modifier, preparation method and application thereof

A modifier and adhesion technology, applied in the direction of adhesive additives, improvement of metal adhesion of insulating substrates, adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

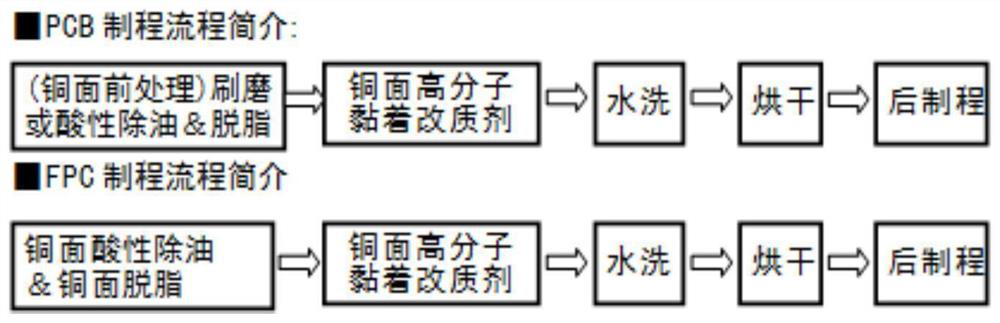

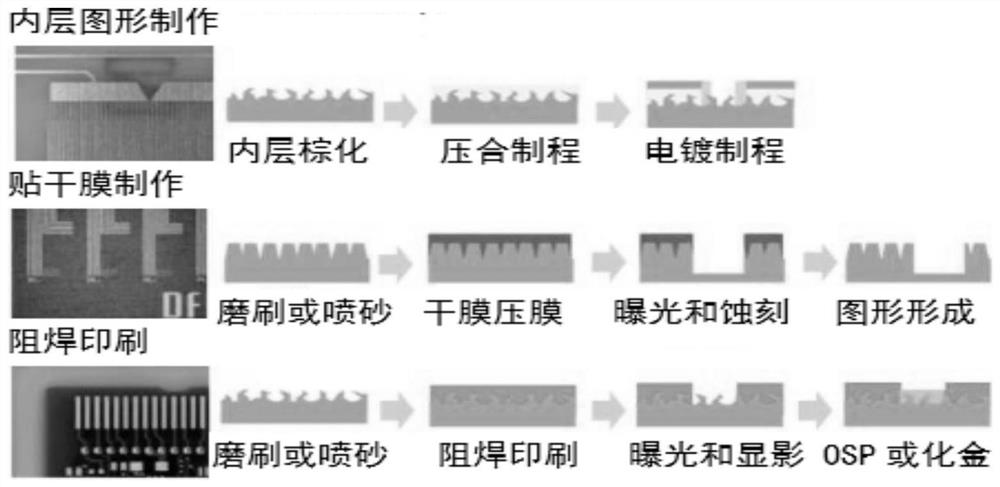

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1. A kind of preparation method of copper surface adhesion modifier

[0050] This example mainly describes a preparation method of a copper surface adhesion modifier. The formula of the copper surface adhesion modifier includes the following chemical components: bank revetment agent 5g / L, sodium hydroxide 10g / L, organic acid 20g / L, stabilizer 16g / L, accelerator 0.1g / L, wetting agent 3g / L.

[0051] The following is the preparation process of 1L copper surface adhesion modifier:

[0052] ①Put 100ml of deionized water (DI water) into a 500ml glass, weigh 10g of sodium hydroxide with an electronic scale (accurate 0.01g), then add it into the water while stirring until it is completely dissolved, then use an electronic scale (accurate 0.01g) ) After weighing 5g bank protection agent (phenylacryltriazole), add in the above-mentioned sodium hydroxide solution while stirring, until fully dissolving and clarifying;

[0053] ②Put 300ml of deionized water (DI water) ...

Embodiment 2

[0055] Example 2. Comparative experiment on the application performance of a copper surface adhesion modifier

[0056] In this example, a performance comparison experiment of the copper surface adhesion modifier described in Example 1 is mainly carried out. For this reason, the inventor has configured the microetching agent of 1L shown in Table 1, the medium roughening solution of 1L, the super-roughening solution of 1L and the copper surface adhesion modifier of 1L described in Example 1 (Example 1 Preparation), the prepared 4 sample solutions were heated to 25°C, and the control parameters of the bath solution were adjusted, as shown in Table 1.

[0057] Table 1. Configuration of microetching agent, medium roughening solution, super roughening solution and copper surface adhesion modifier

[0058]

[0059] Prepare and use four DUMMY boards (Kingboard Chemical Group Co., Ltd.) of the same specification to be scrapped with the same age (here, 6 years) and put them into dif...

Embodiment 3

[0063] Embodiment 3. A kind of preparation method of copper surface adhesion modifier

[0064] This example mainly describes a preparation method of a copper surface adhesion modifier. The formula of the copper surface adhesion modifier includes the following chemical components: bank revetment agent 4g / L, sodium hydroxide 8g / L, organic acid 15g / L, stabilizer 10g / L, accelerator 0.01g / L, wetting agent 20g / L.

[0065] The following is the preparation process of 1L copper surface adhesion modifier:

[0066] ①Put 100ml of deionized water (DI water) into a 500ml glass, weigh 8g of sodium hydroxide with an electronic scale (accurate 0.01g), then add it into the water while stirring until it is completely dissolved, then use an electronic scale (accurate 0.01g) ) After weighing 4g bank protection agent (phenylacryltriazole), add in the above-mentioned sodium hydroxide solution while stirring, until completely dissolving and clarifying;

[0067] ②Put 300ml of deionized water (DI wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com