Composite hydrogel with synchronous evaporation heat dissipation and waste heat recovery capabilities, and preparation method and heat management method thereof

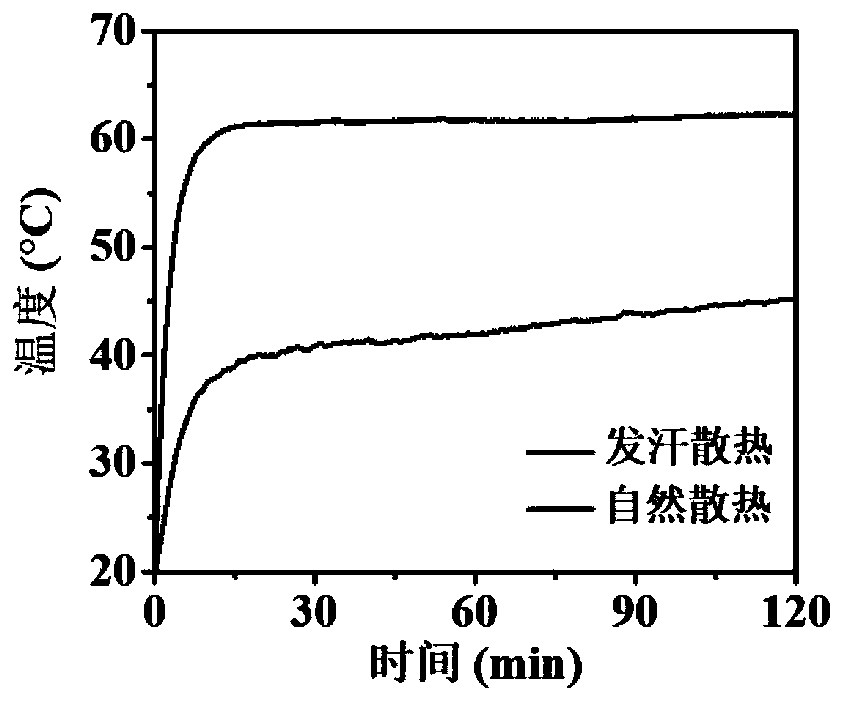

A technology of composite hydrogel and waste heat recovery, which is applied in the direction of cooling/ventilation/heating transformation, modification with liquid cooling, etc. It can solve the problems of high heat source, waste heat, waste, and inability to realize automatic water replenishment, etc., and achieve excellent heat dissipation capacity and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

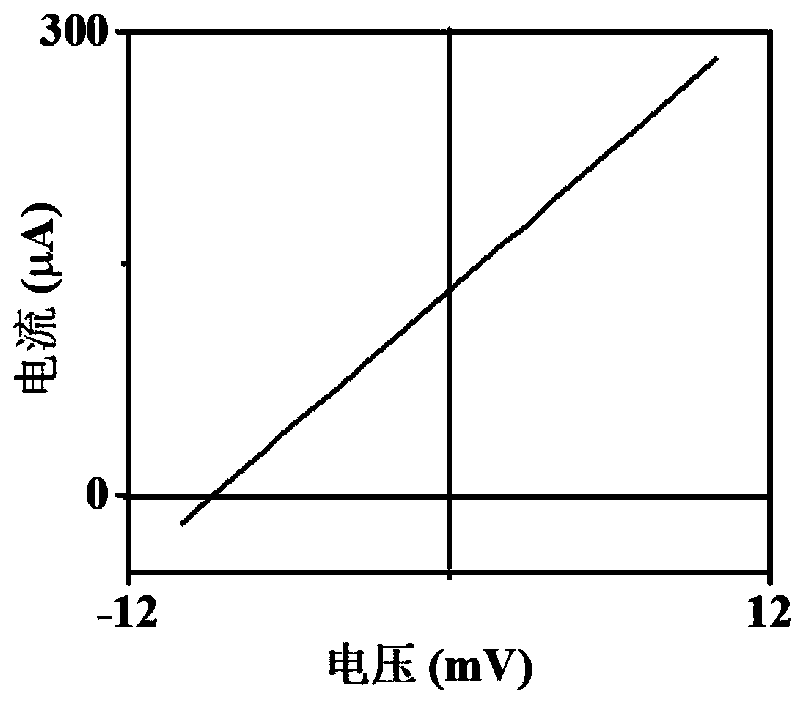

[0030] The invention provides a composite hydrogel for heat management on the surface of a heat source and reuse of waste heat. The composite hydrogel with simultaneous evaporation and heat dissipation and waste heat recovery refers to polyacrylamide hydrogel with a certain concentration of hygroscopic salt and Materials composed of solutions of chemical thermoelectric materials. The hygroscopic salt is lithium bromide, lithium chloride, calcium chloride, etc., with a molar concentration of 0-17.3mol / L. The chemical thermoelectric material is potassium ferricyanide / potassium ferrocyanide or potassium ferricyanide / ammonium ferrocyanide, etc., with a molar concentration of 0-0.4mol / L. The surface of the composite hydrogel with simultaneous evaporative heat dissipation and waste heat recovery capability is smooth and smooth, and can directly cover the surface of a heat source. The concentration of the mixed solution composed of hygroscopic salts and chemical thermoelectric mater...

Embodiment 1

[0038] Provided in this example, the specific preparation method of the composite hydrogel with simultaneous evaporation and heat dissipation and waste heat recovery capabilities is as follows:

[0039] Step 1, 2M acrylamide as monomer, 0.001M N,N'-dimethylbisacrylamide as crosslinking agent, 0.002M 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylbenzene Acetone was used to prepare a mixed solution for the UV initiator.

[0040] Step 2. Pour the solution obtained in step 1 into 10×5×3.6cm 3 in the mold.

[0041] Step 3, using a UV lamp to cure for 8 hours under a nitrogen atmosphere to obtain a polyacrylamide hydrogel.

[0042] Step 4. Take out the polyacrylamide hydrogel from the mold, and place it on a heating platform at 60° C. until it is completely dry.

[0043] Step 5. Submerge the dried polyacrylamide hydrogel in a mixed solution of potassium ferricyanide / potassium ferrocyanide (0.1M) and lithium bromide (9.4M) until it swells completely.

[0044] Step 6. Take out the gel, w...

Embodiment 2

[0048] The specific preparation method of the composite hydrogel with simultaneous evaporation and heat dissipation and waste heat recovery capabilities provided in this example is as follows:

[0049] Step 1, 2M acrylamide as monomer, 0.001M N,N'-dimethylbisacrylamide as crosslinking agent, 0.002M 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylbenzene Acetone was used to prepare a mixed solution for the UV initiator.

[0050] Step 2. Pour the mixed solution obtained in step 1 into 10×6×2cm 3 in the mold.

[0051] Step 3, using a UV lamp to cure for 8 hours under a nitrogen atmosphere to obtain a polyacrylamide hydrogel.

[0052] Step 4. Take out the polyacrylamide hydrogel from the mold, and place it on a heating platform at 60° C. until it is completely dry.

[0053] Step 5. Submerge the dried polyacrylamide hydrogel in a mixed solution of potassium ferricyanide / potassium ferrocyanide (0.1M) and lithium bromide (5.4M) until it swells completely.

[0054] Step 6. Take out the gel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com