Part clamp for batch machining of non-standard parts and electric discharge machining jig

A batch processing and part clamping technology, applied in the field of fixtures, can solve the problems of a single number of fixtures, unable to be clamped and fixed, not satisfying batch processing, etc., to improve processing efficiency, improve verticality and stability, The effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

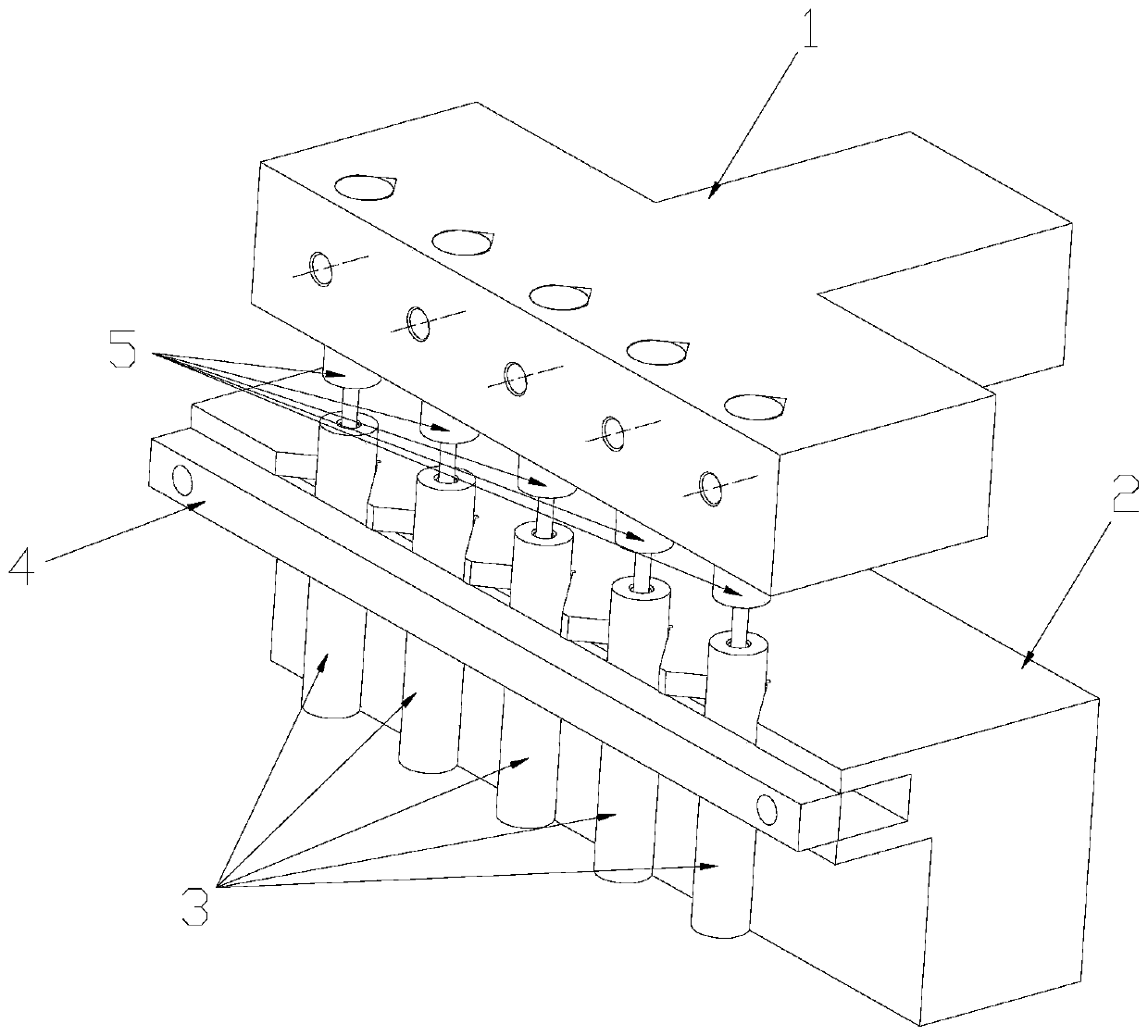

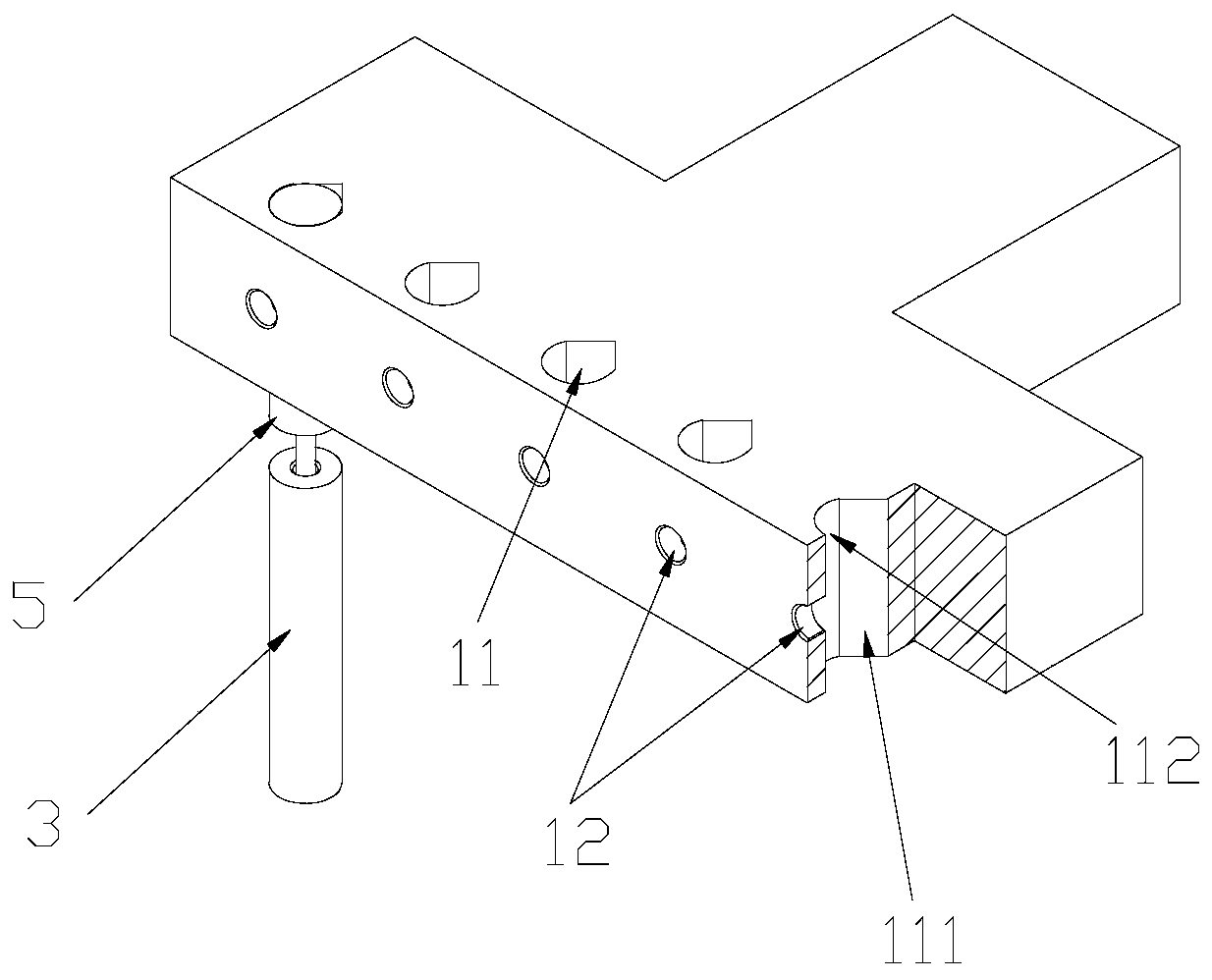

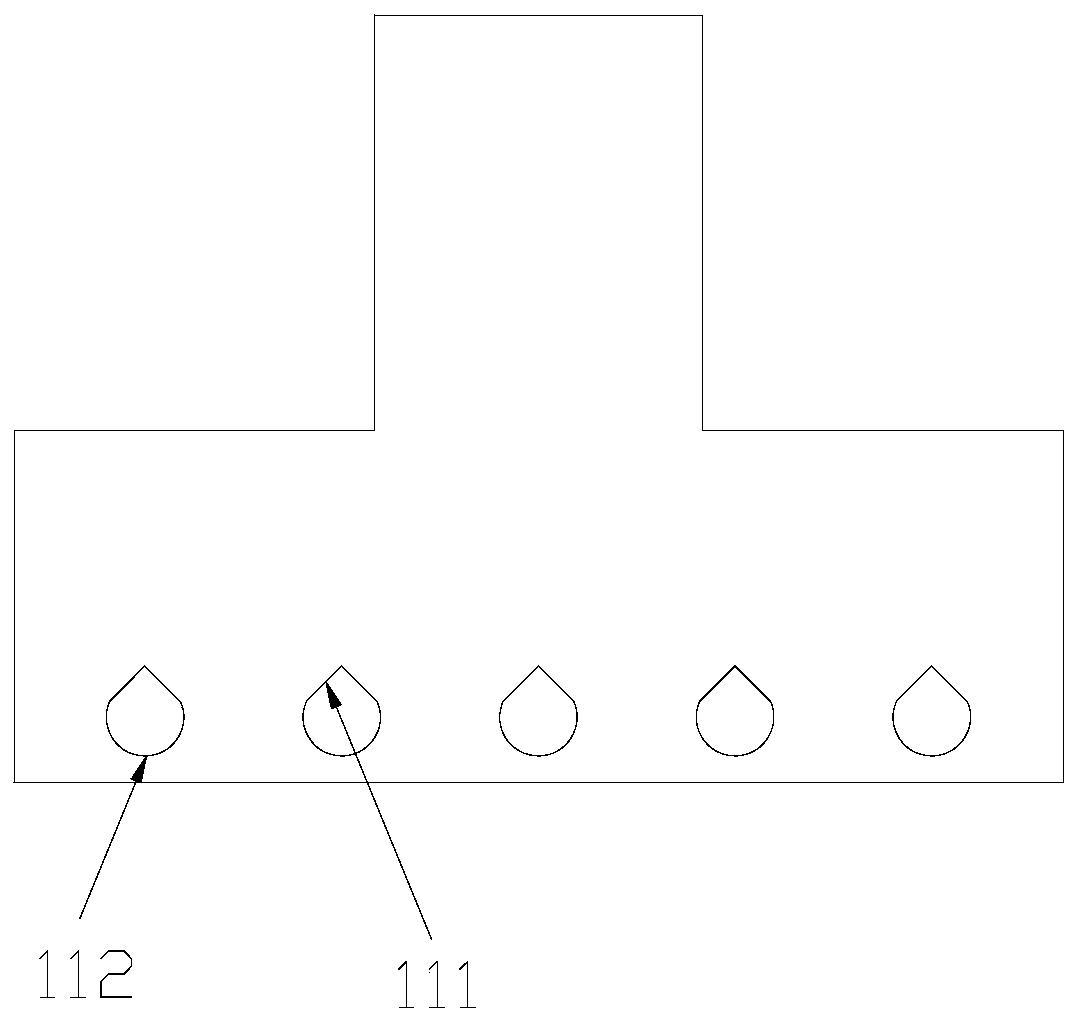

[0031] Such as figure 1 As shown, a batch processing fixture for non-standard parts 3 of the present invention includes an electrode fixture 1 and a part fixture. The electrode fixture and the part fixture can be used in combination or alone. The number of fixed non-standard parts 3 can be set according to needs. In this embodiment, the structure of each part of the jig is described by taking the processing of five non-standard parts 3 at one time as an example. Specifically, the non-standard parts 3 have a unified A cylindrical or elongated part of a feature. The electrode fixture 1 is located above the part fixture, but the upper and lower positions of the two are not limite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com