Material-collecting fixture for thermal simulation compression sample during linear cutting and bisecting

A technology of thermal simulation compression and wire cutting, used in manufacturing tools, electric processing equipment, metal processing equipment, etc. The effect of clip stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

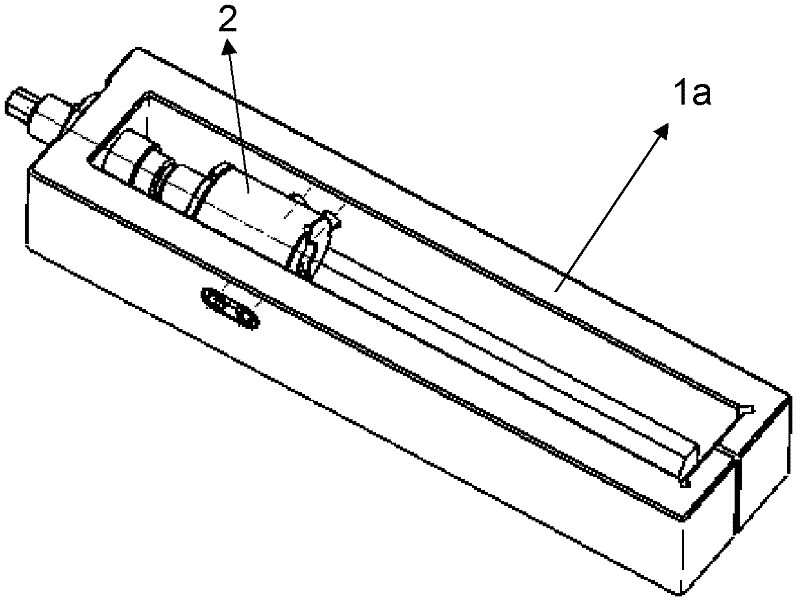

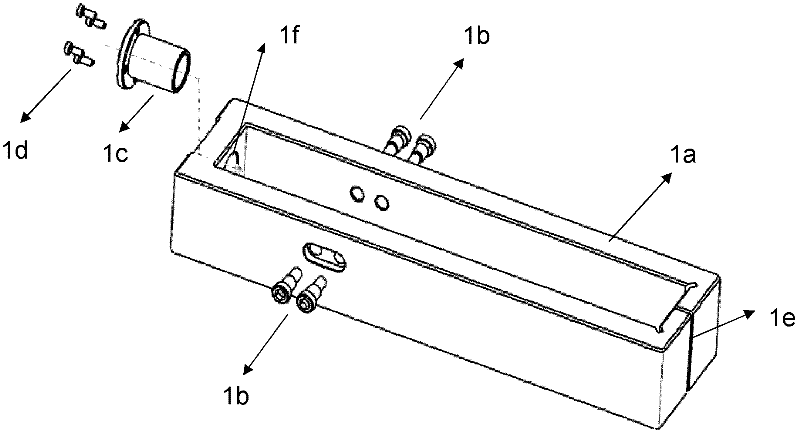

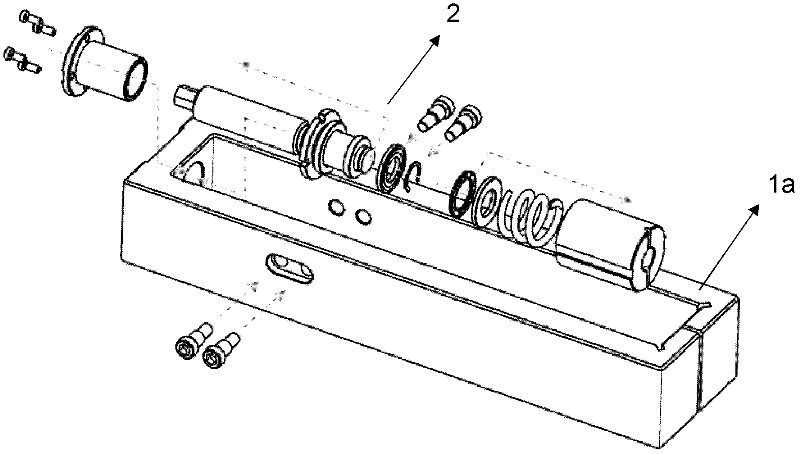

[0034] Such as Figure 1 to Figure 5 As shown, a kind of collection fixture for thermal simulated compression sample line cutting, including a hollow rectangular frame 1a and a pressing rod assembly 2 arranged in the rectangular frame, one end of the rectangular frame has a longitudinal The central notch 1e, the width of the longitudinal centering notch is 1mm-2mm larger than the diameter of the molybdenum wire.

[0035] A through hole 1f with an internal thread is opened in the center of the other end of the frame, and the pressure rod assembly 2 includes a driving screw 2g, one end of which passes through the through hole 1f and forms a threaded connection with the rectangular frame, close to the other end A stepped transparent cover 2h is fixedly sleeved on the transmission screw rod of the head 2k, and a cylindrical sleeve 2a is sleeved on the transparent cover. One end of the cylindrical sleeve close to the stepped transparent cover is open, and the other end has an end c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com