A kind of sling for sand core of semi-suspension wall structure and its hoisting method

A sand core and hanging wall technology, which is applied in the field of 3D printing sand core product laying aids, can solve problems such as fracture, and achieve the effects of preventing dumping, avoiding fracture, and changing the clamping method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

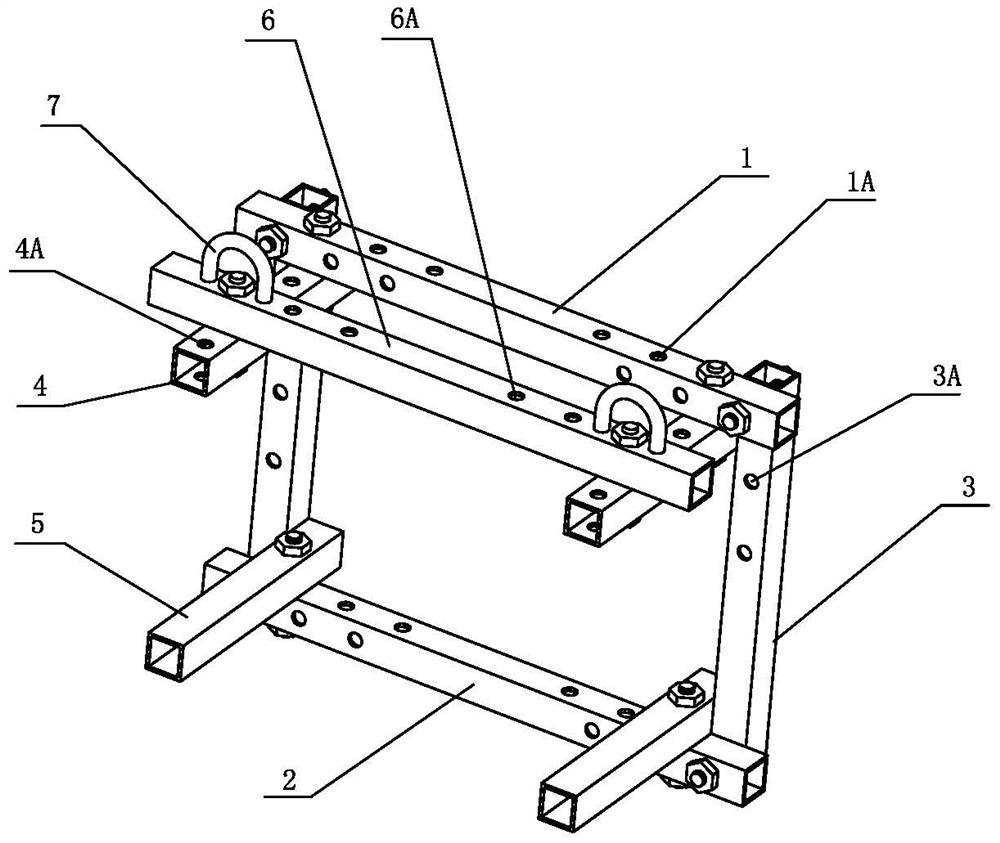

[0019] Such as figure 2 Shown is the hanger for the sand core of the semi-cantilever structure of the present invention, comprising a rectangular frame connected by section steel, which is vertically arranged, and the rectangular frame includes an upper beam 1, a lower beam 2 and connecting the upper beam 1 and The two columns 3 of the lower beam 2, the upper beam 1 is horizontally connected with two upper beams 4, the lower beam 2 is horizontally connected with two lower beams 5, and the upper beam 4 and the lower beam 5 are located on the same side of the rectangular frame. On the side, the lifting beam 6 is also connected between the upper support beams 4, and the upper side of the lifting beam 6 is provided with lifting lugs 7. In order to facilitate the installation and connection of the parts of the spreader and ensure the connection strength and rigidity, the upper beam, lower beam, column, upper support beam, lower support beam, lifting beam and pull rod in the spread...

Embodiment 2

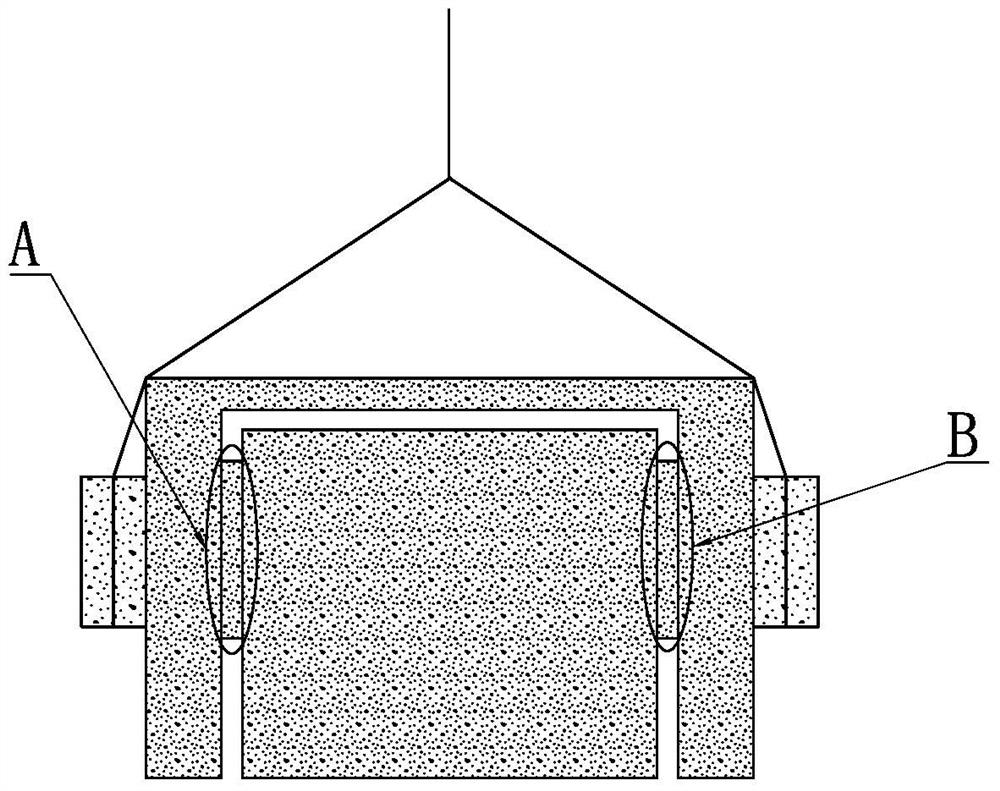

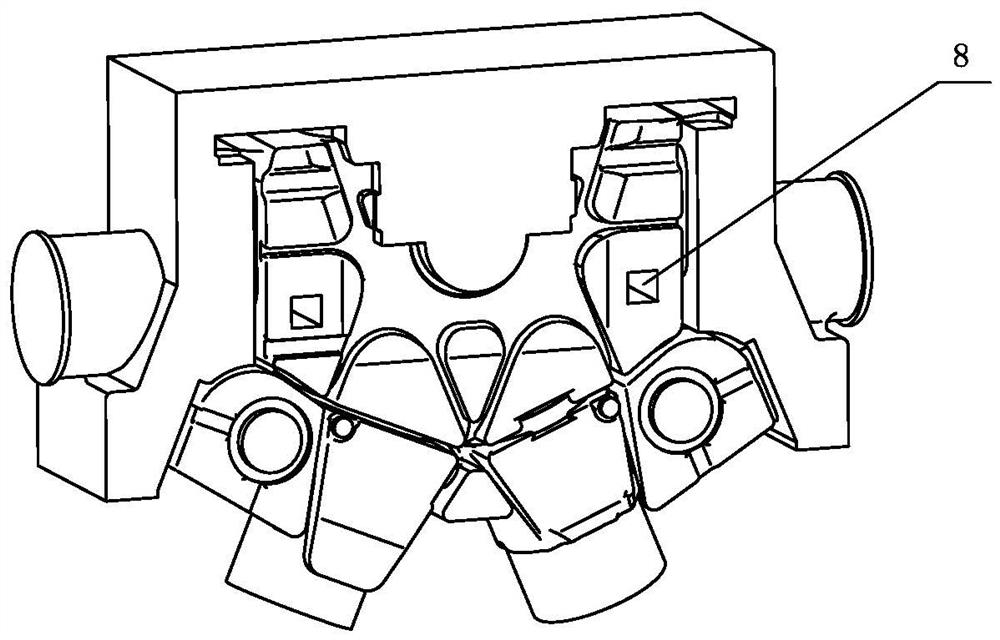

[0023] Take the example image 3 Take the sand core structure as an example, describe in detail the method for lifting the sand core with a hanger for the semi-cantilever structure sand core of the above-mentioned embodiment 1, image 3 The sand core product shown is a 3D printed sand core for an internal combustion engine body. In this sand core structure, the weight of the main body of the sand core is located in the core part inside the sand core. The core part and the external core structure are in a semi-hanging state. In the prior art, during the lifting process of the sand core assembly, the lifting handle is used to hang the outer side of the sand core. After the sand core is lifted, the internal molding sand is prone to stress concentration due to the action of gravity And break, causing damage to the sand core. When the sand core is hoisted with the spreader in Example 1, the occurrence of the above-mentioned damage problem is completely avoided. The specific proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com