Preparation method of CuSn10 powder with low bulk density

A low bulk and density technology, applied in the field of powder metallurgy, can solve the problems of difficult control of sintering size change rate, unsatisfactory flow rate and bulk ratio performance, uneven powder composition, etc., to achieve good compressibility, stable shrinkage rate, flow good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

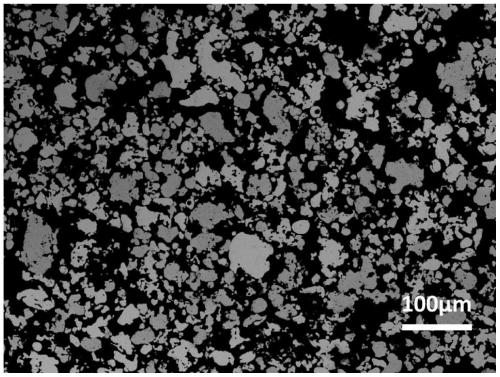

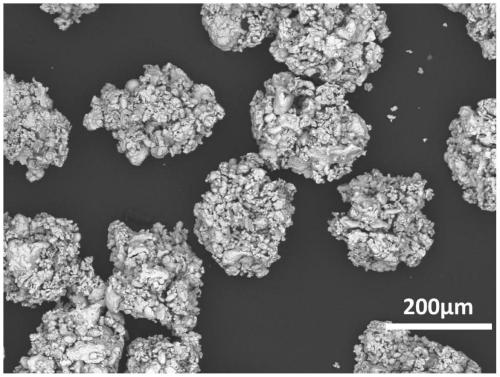

[0021] Embodiment 1: a kind of preparation method of CuSn10 powder with low bulk density mainly includes the following contents:

[0022] (1) The pure copper powder prepared by the water atomization method is selected, and the particle size of the water atomized pure copper powder is -200 mesh.

[0023] (2) The copper-tin alloy powder prepared by the water atomization method is selected, the particle size is -200 mesh, and the tin content is 20%.

[0024] (3) The above-mentioned pure copper powder and copper-tin alloy powder are selected and mixed in a ratio of 1:1. In order to prevent segregation, 0.2% adhesive is added during the powder mixing process. The ingredients of the adhesive are: thermoplastic 0.03% styrene-butadiene rubber, 3% ethyl acetate, 96.7% alcohol.

[0025] (4) Put the mixed powder into the reduction furnace, and carry out sintering and granulation at the reduction temperature of 500°C.

[0026] (5) The sintered powder is crushed and screened, and the fin...

Embodiment 2

[0027] Embodiment two: a kind of preparation method of low bulk density CuSn10 powder mainly comprises the following contents:

[0028] (1) The pure copper powder prepared by the water atomization method is selected, and the particle size of the water atomized pure copper powder is -200 mesh.

[0029] (2) The copper-tin alloy powder prepared by the water atomization method is selected, the particle size is -200 mesh, and the tin content is 30%.

[0030] (3) The above-mentioned pure copper powder and copper-tin alloy powder are selected and mixed in a ratio of 2:1. In order to prevent segregation, 0.2% adhesive is added during the powder mixing process. The components of the adhesive are: thermoplastic 0.03% styrene-butadiene rubber, 3% ethyl acetate, 96.7% alcohol.

[0031] (4) Put the mixed powder into the reduction furnace for sintering and granulation: the reduction temperature is 700°C.

[0032] (5) The sintered powder is crushed and screened, and the finished powder is ...

Embodiment 3

[0033] Embodiment three: a kind of preparation method of low bulk density CuSn10 powder mainly comprises the following contents:

[0034] (1) The pure copper powder prepared by the water atomization method is selected, and the particle size of the water atomized pure copper powder is -200 mesh.

[0035] (2) The copper-tin alloy powder prepared by the water atomization method is selected, the particle size is -200 mesh, and the tin content is 15%.

[0036] (3) Use the above-mentioned pure copper powder and copper-tin alloy powder to mix uniformly in a ratio of 1:2. In order to prevent segregation, add 0.2% adhesive during the powder mixing process. The mass fraction ratio of the adhesive is: : Thermoplastic styrene-butadiene rubber 0.03%, ethyl acetate 3%, alcohol 96.7%.

[0037] (4) Put the mixed powder into the reduction furnace for sintering and granulation: the reduction temperature is 600°C.

[0038] (5) Crushing and sieving the sintered powder, and adjusting the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com