Automatic metallurgical heating agent adding device for continuous casting and collecting tailing billet

A heating agent and continuous casting technology, which is applied in the field of continuous casting technology and equipment in the metallurgical industry, can solve the problems of large tail blank quality differences, long adding time, large randomness, etc., and achieve improved molten steel yield, reduced solidification rate, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

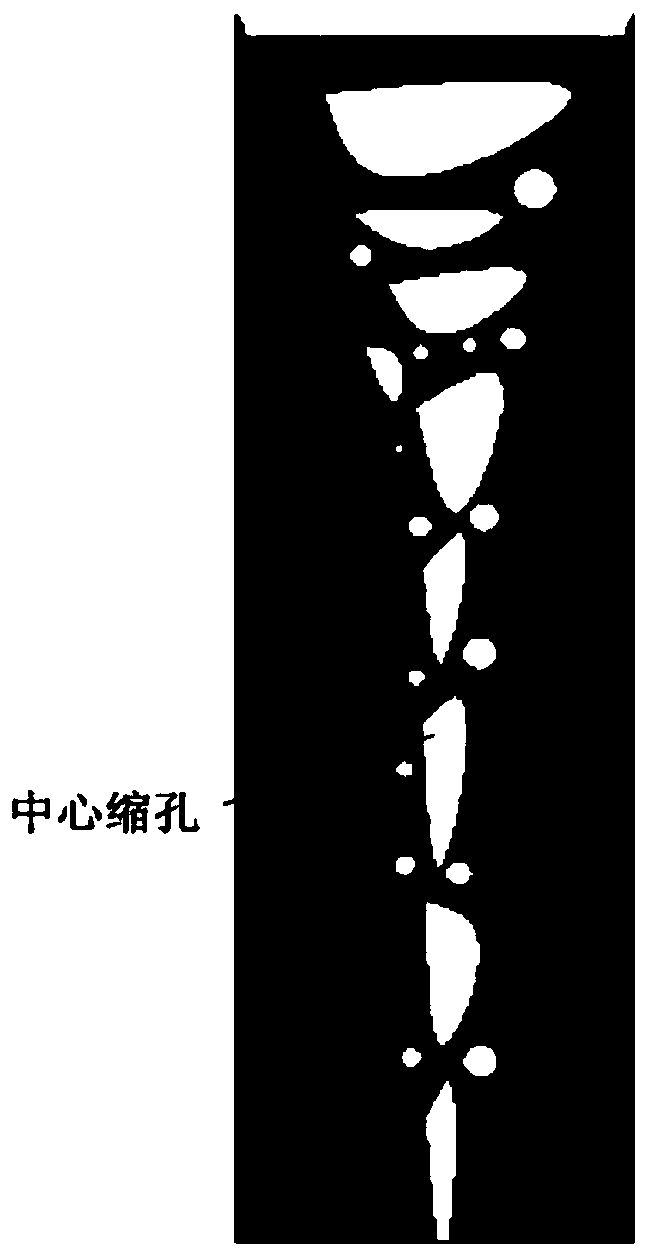

Problems solved by technology

Method used

Image

Examples

Embodiment 1

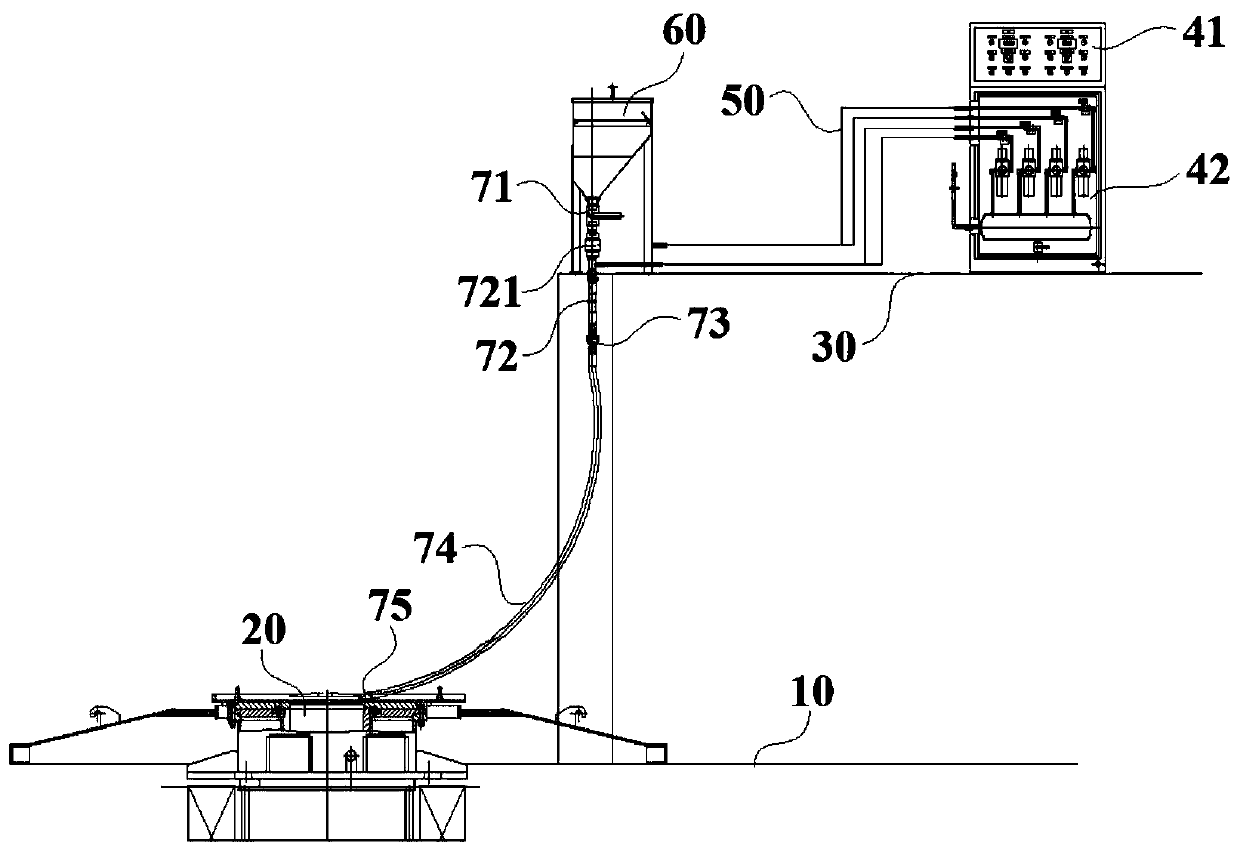

[0043] A device for automatically adding metallurgical exothermic agent for continuous casting final billet in this embodiment, the overall arrangement in the continuous casting steel pouring area is as follows figure 2 As shown, it includes a control cabinet, a heating agent silo 60, a metallurgical heating agent feeding pipe 74 and a nozzle 75; wherein, the control cabinet is installed on the ladle operating platform 30, and its principle is to use a PLC control system to control and improve The degree of automation of the entire automatic joining device, such as figure 2 As shown, the control cabinet in this embodiment is divided into upper and lower parts. The upper part of the control cabinet is an injection control panel 41, which is a touch screen, and is used to control the start and stop of subsequent metallurgical heating agents, and control the addition of metallurgical heating agents to crystallization. The time of the device, etc.; the bottom of the control cabi...

Embodiment 2

[0069] The device for automatically adding metallurgical exothermic agent for continuous casting billet in this embodiment is basically the same as that of Embodiment 1, the difference is that the metallurgical exothermic agent feeding pipe 74 and the transition pipe 72 in this embodiment are connected by a tie The quick joint 73 is connected with each other, and the metallurgical exothermic agent feeding pipe 74 can be replaced quickly through the pull rod type quick joint 73, which greatly reduces the maintenance or replacement time of the automatic adding device, and is convenient for the operator to operate.

[0070] Preferably, the metallurgical exothermic agent feeding pipe 74 of this embodiment is also connected to the nozzle 75 through a pull-rod quick connector 73, and the rapid replacement of the nozzle 75 can be realized through the pull-rod quick connector 73, and the operator can process and produce according to actual conditions. If necessary, replace different no...

Embodiment 3

[0072] A device for automatically adding metallurgical exothermic agent for continuous casting billets in this embodiment is basically the same as that in Embodiment 2, except that:

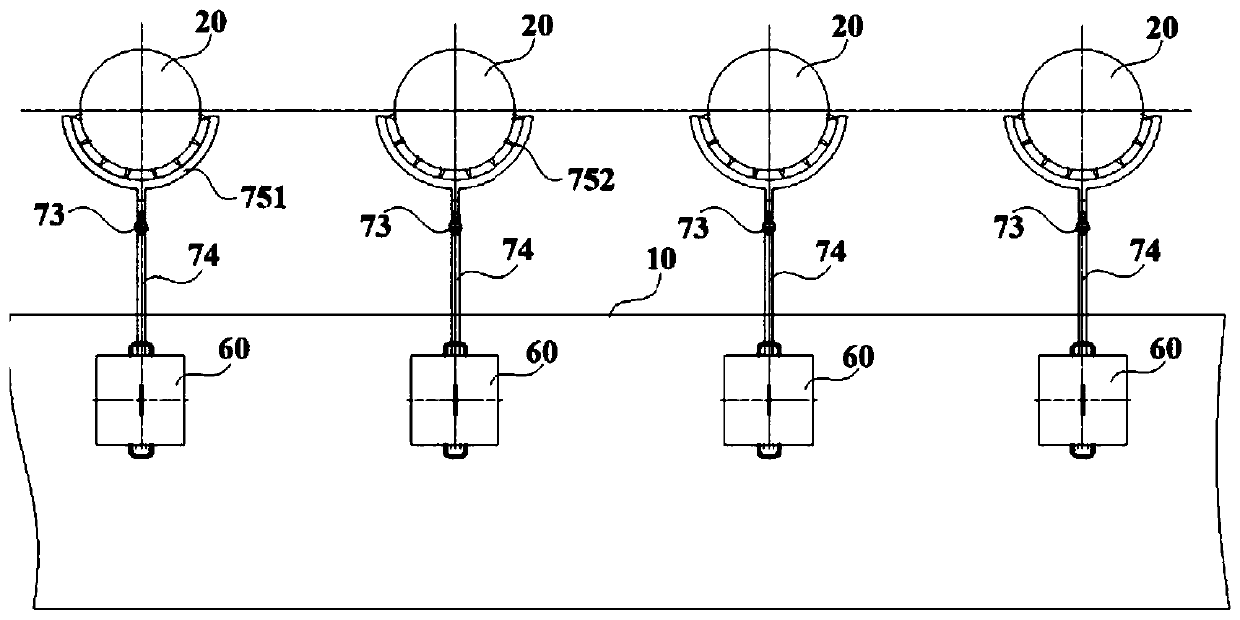

[0073] In order to facilitate the uniform addition of the metallurgical heating agent into the crystallizer, so that the metallurgical heating agent can cover the entire molten steel surface more uniformly, and the automatic adding device can adapt to casting billets with different sections. In this embodiment, four-strand round billets are used as the E.g image 3As shown, the nozzle 75 of this embodiment is a special nozzle 75 for round billet continuous casting. The nozzle 75 of this embodiment includes a main body 751 and a nozzle 752, wherein one end of the main body 751 is connected with the metallurgical exothermic agent feeding pipe 74, and the main body The other end of 751 communicates with shower head 752 .

[0074] The main body 751 of this embodiment has a semicircular structure, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com