Preparation method of monodisperse high-load hydrophilic ion exchange polymethacrylate microspheres

A technology of polymethacrylate and polymethacrylic acid, which is applied in the direction of cation exchange materials, can solve problems such as limiting the scope of application, and achieve the effects of stable physical and chemical properties, simple cleaning and regeneration, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

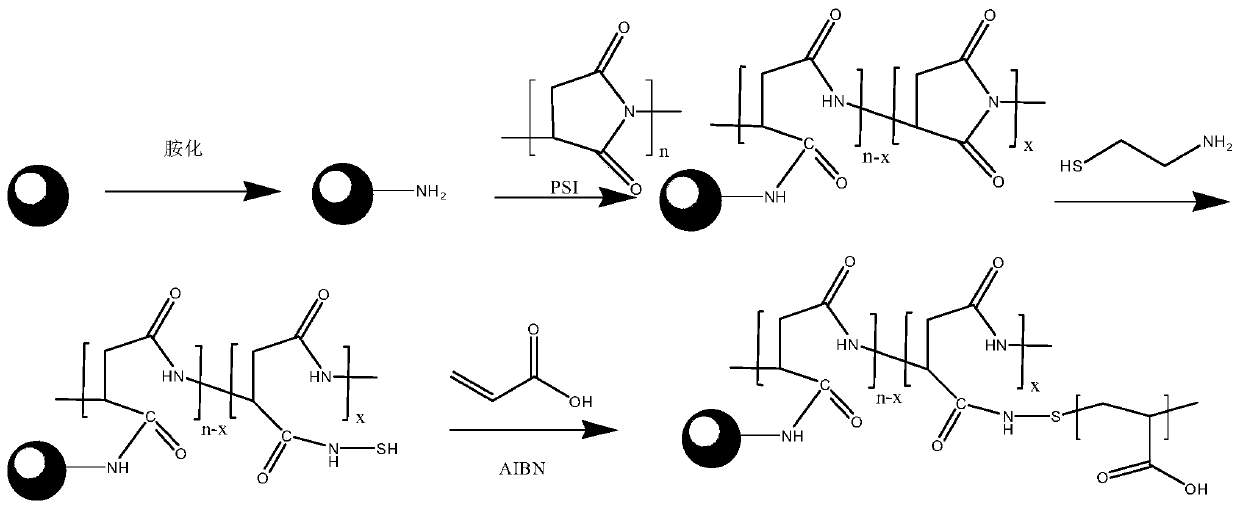

[0024] Such as figure 1 As shown, a preparation method of monodisperse high-capacity hydrophilic ion-exchange polymethacrylate microspheres, first, the porous polyglycidyl methacrylate microspheres are aminated; then grafted polysuccinyl The amine undergoes a ring-opening reaction, and finally a tentacle-type ion-exchange group is obtained through a radical-initiated reaction with an olefinic monomer, thereby obtaining a hydrophilic high-loading polymethacrylate microsphere.

[0025] The steps of the preparation method are as follows:

[0026] Step 1, adding monodisperse porous polyglycidyl methacrylate microspheres into the reaction kettle, adding a solvent and ultrasonically mixing, then adding an amine reagent and mechanically stirring until uniformly mixed, and reacting at a constant temperature for 12 hours to obtain aminated microspheres; The mass volume (g / mL) ratio of described microsphere and solvent is 0.1, and described solvent adopts the mixed solution of water an...

Embodiment 2

[0033] A method for preparing monodisperse high-capacity hydrophilic ion-exchange polymethacrylate microspheres. First, porous polyglycidyl methacrylate microspheres are subjected to amination treatment; Ring reaction, and finally the tentacle-type ion exchange group is obtained through the free radical reaction with olefinic monomers, so as to obtain hydrophilic high-load polymethacrylate microspheres.

[0034] The steps of the preparation method are as follows:

[0035] Step 1, adding monodisperse porous polyglycidyl methacrylate microspheres into the reaction kettle, adding a solvent and ultrasonically mixing, then adding an amine reagent and mechanically stirring until uniformly mixed, and reacting at a constant temperature for 24 hours to obtain aminated microspheres; The mass volume (g / mL) ratio of described microsphere and solvent is 0.5, and described solvent adopts the mixed liquor of water and methanol, and the mass ratio of water and methanol is 1:3, and described a...

Embodiment 3

[0042] A method for preparing monodisperse high-capacity hydrophilic ion-exchange polymethacrylate microspheres. First, porous polyglycidyl methacrylate microspheres are subjected to amination treatment; Ring reaction, and finally the tentacle-type ion exchange group is obtained through the free radical reaction with olefinic monomers, so as to obtain hydrophilic high-load polymethacrylate microspheres.

[0043] The steps of the preparation method are as follows:

[0044] Step 1, adding monodisperse porous polyglycidyl methacrylate microspheres into the reaction kettle, adding a solvent and ultrasonically mixing, then adding an amine reagent and mechanically stirring until uniformly mixed, and reacting at a constant temperature for 18 hours to obtain aminated microspheres; The mass volume (g / mL) ratio of described microsphere and solvent is 0.3, and described solvent adopts the mixed liquor of water and methanol, and the mass ratio of water and methanol is 1:3, and described a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com