Micro-lens group for obtaining adjustable annular light beam

A ring beam and micro lens technology, applied in the direction of condenser, optics, optical components, etc., can solve the problem that a single axicon lens cannot achieve adjustable ring spot, which is not conducive to the process optimization of different thickness sheets, and is not conducive to the process optimization of different thickness sheets, etc. problems, to achieve the effects of controllable mechanical design and control difficulty, novel structural design, and controllable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

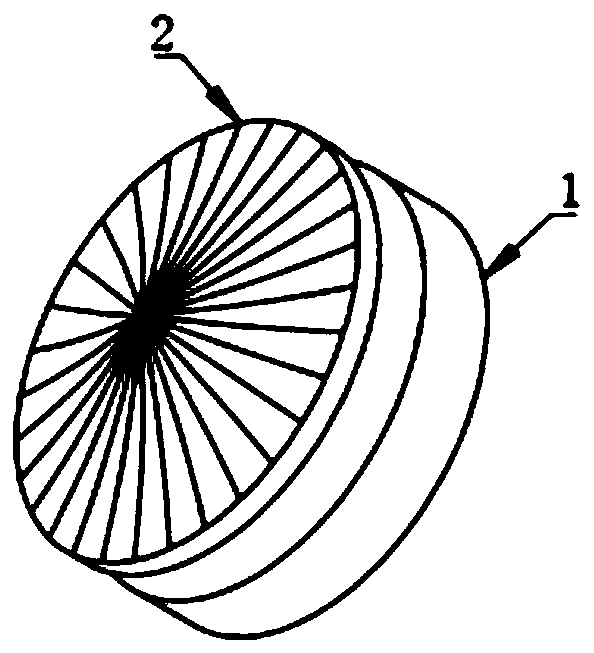

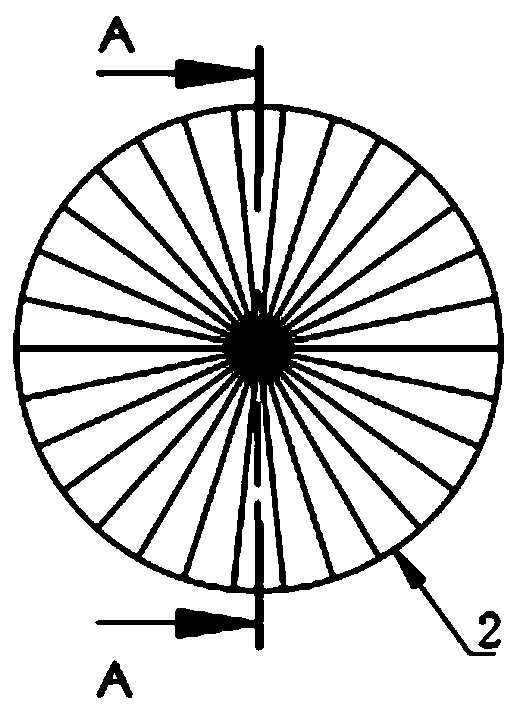

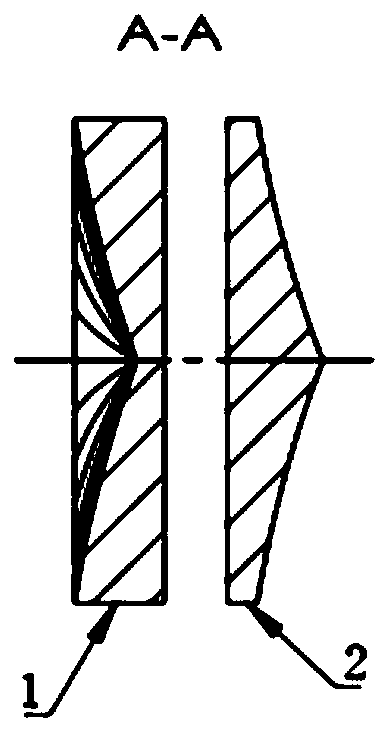

[0028] Figure 1-Figure 3 A microlens group for obtaining an adjustable annular beam is shown, including a plano-concave microlens 1 and a plano-convex microlens 2 .

[0029] In this solution, the central axis of the plano-concave microlens 1 and the plano-convex microlens 2 are coaxial, and the plano-concave microlens 1 or the plano-convex microlens 2 can rotate along the central axis;

[0030] The lens materials of the plano-concave microlens 1 and the plano-convex microlens 2 are fused silica materials;

[0031] The plano-concave microlens 1 and the plano-convex microlens 2 are based on the combination of axicon beam splitting and angular beam splitting, and are axisymmetric angular array microlenses;

[0032] The plano-concave microlens 1 and the plano-convex microlens 2 have the same angular beam splitting units, the number of which satisfies 10 to 100, and all the angular beam splitting units have the same beam splitting angle, and the beam splitting vertices converge i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com