Terrace

A floor and ground technology, applied to building components, layered products, buildings, etc., can solve problems such as surface whitening, roughness, and floor bleeding, and achieve good flame retardancy, enhanced pressure-bearing performance, and improved Wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

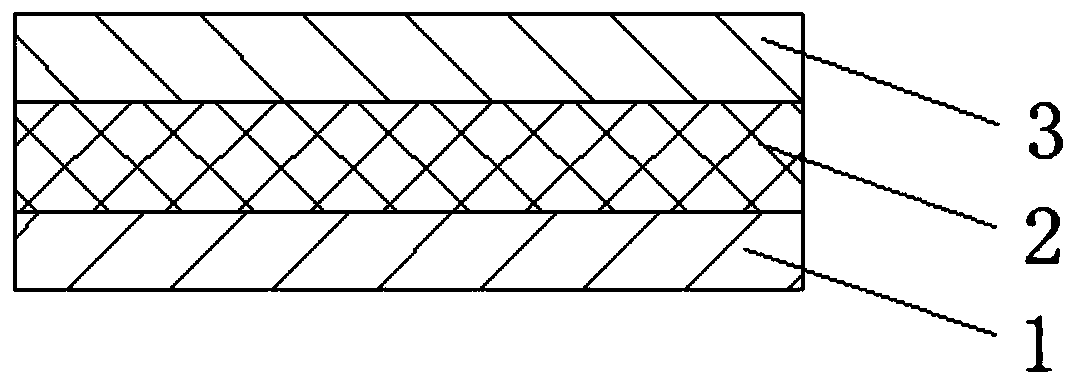

[0044] Embodiment 1: as figure 1 As shown, a floor of the present invention includes a base layer, a middle layer, and a surface layer. The base layer is connected to the ground and has a thickness of 0.3 to 0.8 mm. In this example, 0.8 mm is selected; the middle layer is a pressure-bearing support layer with a thickness of 1 to 15 mm. In this example, 10mm is selected; the surface layer is a wear-resistant and anti-aging layer, and the thickness is 1-3mm, and 1mm is selected in this example. The base layer mainly plays the role of full connection with the foundation, the middle layer mainly plays the role of support and load-bearing, and the surface layer is mainly beautiful, wear-resistant and applicable.

[0045] The viscosity of the base layer material is 500-1500mpa.s; the viscosity of the middle layer is 3000-6000mpa.s.

[0046] The base layer is composed of epoxy resin, curing agent and diluent, in parts by mass:

[0047] Epoxy resin: 100 parts,

[0048] Curing agent...

Embodiment 2

[0075] Embodiment 2: what this example is different from embodiment 1 is: the base layer thickness of terrace of the present invention is 0.3mm, and middle layer thickness is 15mm, and surface layer thickness is 3mm.

[0076] The base layer is composed of epoxy resin, curing agent and diluent, in parts by mass:

[0077] Epoxy resin: 100 parts,

[0078] Curing agent: 50 parts,

[0079] Thinner: 20 parts,

[0080] The viscosity of the base material is 500-1500mpa.s.

[0081]Described middle layer material is counted in parts by mass:

[0082] Epoxy resin: 100 parts,

[0083] Curing agent: 45 parts,

[0084] Aluminum hydroxide powder: 80 parts,

[0085] Quartz sand: 50 parts,

[0086] Toughener: 12 parts,

[0087] Thinner: 15 parts,

[0088] Defoamer: 2 parts,

[0089] Leveling agent: 0.9 parts.

[0090] Described surface layer material is counted in parts by mass:

[0091] Epoxy resin: 100 parts,

[0092] Curing agent: 40 parts,

[0093] Pigment: 15 parts,

[0094...

Embodiment 3

[0101] Embodiment 3: this example is different from embodiment 1 in that: the base layer thickness of the terrace of the present invention is 0.6mm, the middle layer thickness is 1mm, and the surface layer thickness is 2mm.

[0102] The base layer is composed of epoxy resin, curing agent and diluent, in parts by mass:

[0103] Epoxy resin: 100 parts,

[0104] Curing agent: 46 parts,

[0105] Thinner: 18 parts,

[0106] The viscosity of the base material is 500-1500mpa.s.

[0107] Described middle layer material is counted in parts by mass:

[0108] Epoxy resin: 100 parts,

[0109] Curing agent: 40 parts,

[0110] Aluminum hydroxide powder: 40 parts,

[0111] Quartz sand: 70 parts,

[0112] Toughener: 8 parts,

[0113] Thinner: 5 parts,

[0114] Defoamer: 1.5 parts,

[0115] Leveling agent: 0.7 parts.

[0116] Described surface layer material is counted in parts by mass:

[0117] Epoxy resin: 100 parts,

[0118] Curing agent: 50 parts,

[0119] Pigment: 25 parts, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com