A kind of preparation method of the catalyst that is used for vocs catalytic oxidation

A catalytic oxidation and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of reduced catalyst service life, poor catalytic activity, high light-off temperature, etc., to achieve good catalytic effect, Reduced usage, moderate intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

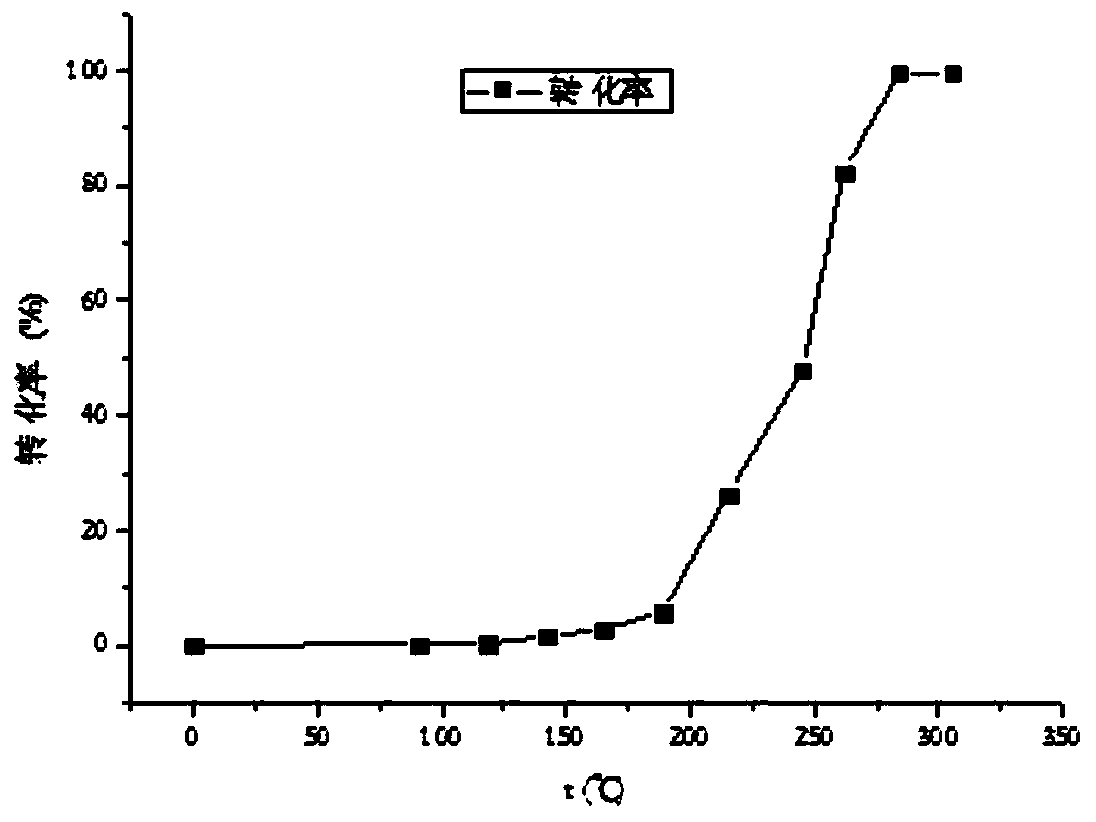

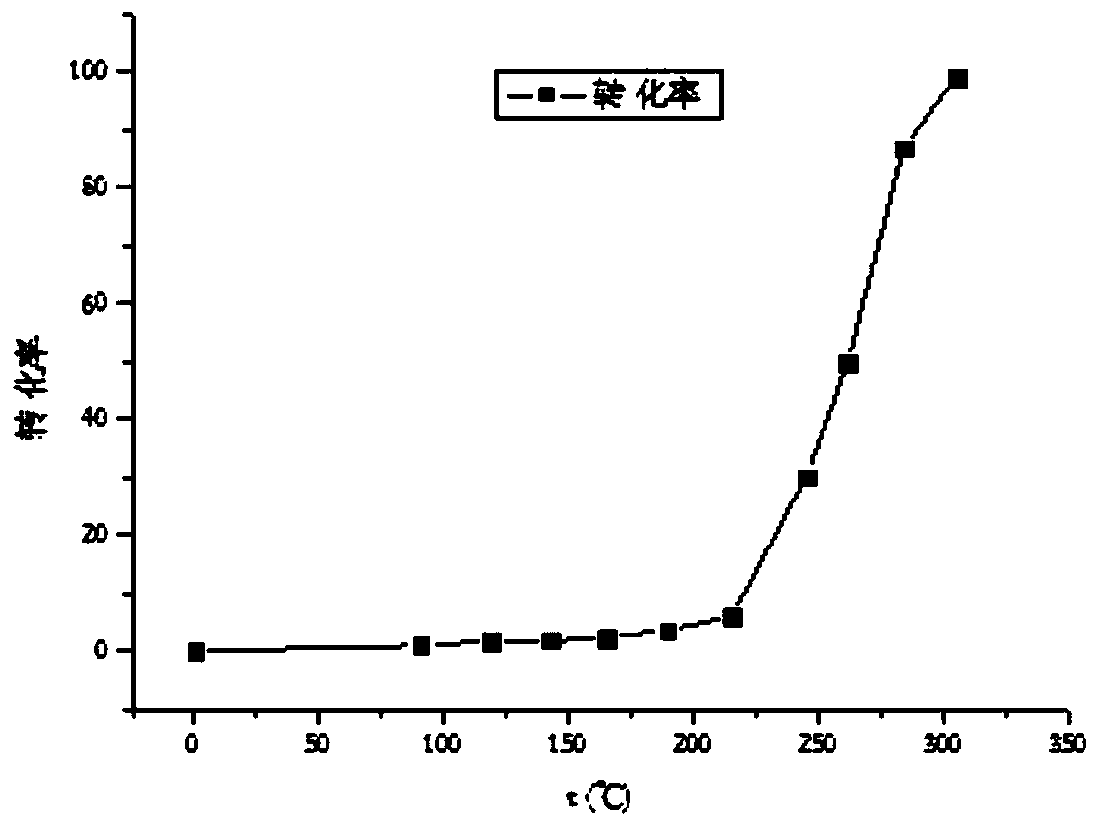

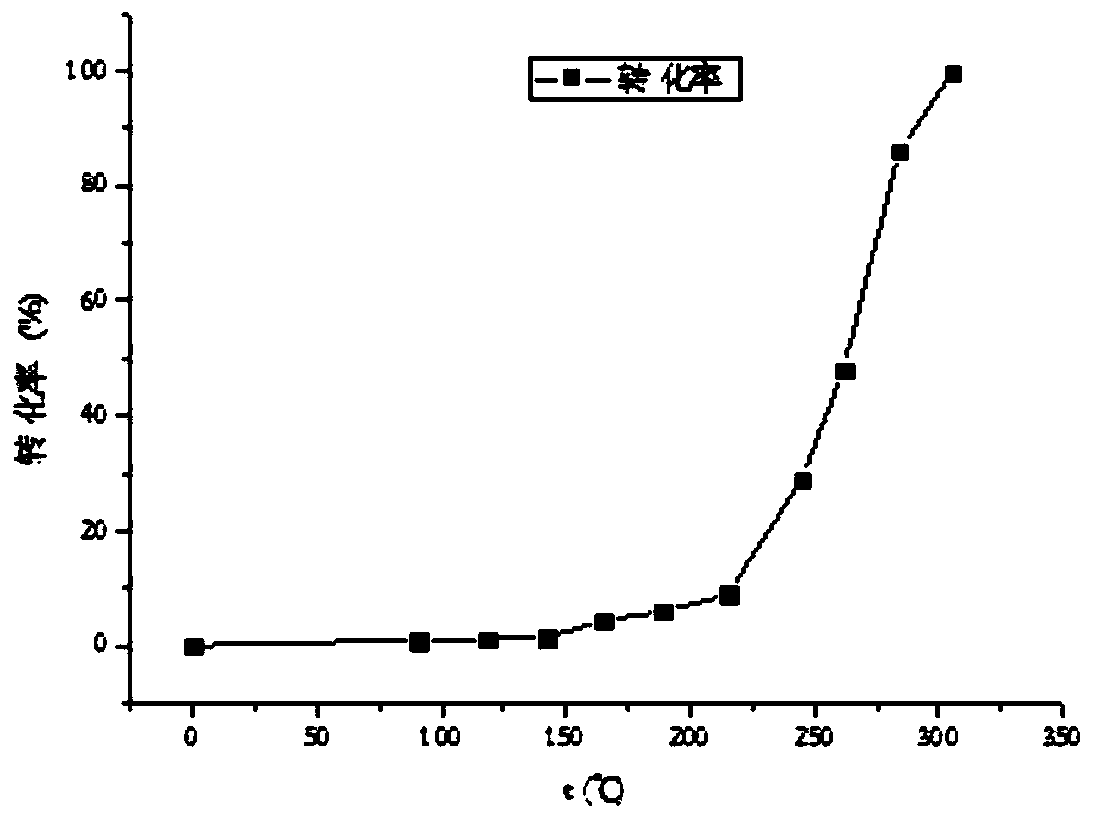

Image

Examples

preparation example Construction

[0022] A preparation method for a catalyst for VOCs catalytic oxidation, comprising the following steps:

[0023] (1) Dissolve NaOH solid and 3-mercaptopropyltrimethylsilane in deionized water at a molar ratio of 20 to 25:1, and stir magnetically at 20 to 25°C to obtain the first ligand solution, usually stirring for 8 hours That’s it; in this process, the methanol produced by the hydrolysis of the 3-mercaptopropyltrimethylsilane ligand is all volatilized to prevent the subsequent addition of gold ions from being reduced;

[0024] (2) the chloroauric acid solid that contains crystal water is dissolved in water, is configured into chloroauric acid solution, drips hydrochloric acid and makes the pH of chloroauric acid solution remain between 5~6.5, to prevent the chloroauric acid solution from decomposing; then The prepared chloroauric acid solution and the first ligand solution are magnetically stirred and mixed according to the molar ratio of chloroauric acid: 3-mercaptopropyl...

Embodiment 1

[0031] (1) Dissolve 4.00g of NaOH solid and 0.82g of 3-mercaptopropyltrimethylsilane ligand in deionized water, and magnetically

[0032] Stir for 8 hours;

[0033] (2) 0.23g of chloroauric acid solid containing crystal water is dissolved in water, configured into a chloroauric acid solution, and a few drops of hydrochloric acid are added dropwise to make the pH value of the chloroauric acid solution at 5, preventing it from decomposing; the chloroauric acid solution Add dropwise to the above ligand solution, stir magnetically for 0.5h to make it evenly mixed;

[0034] (3) Take 8.10g colloidal SiO 2 Place in a sealed plastic container, stir magnetically at 80°C for 50 minutes, and then mix with the above ligand solution;

[0035] (4) 4.92g NaAlO 2 The solid was dissolved in deionized water, added dropwise to the ligand solution mixed with silica colloidal solution, and magnetically stirred at 25°C for 2 hours to form a gel solution;

[0036] (5) The above gel solution was ma...

Embodiment 2

[0042] (1) Dissolve 5.00 g of NaOH solid and 0.82 g of 3-mercaptopropyltrimethylsilane ligand in deionized water, and stir magnetically at 22°C for 8 hours;

[0043] (2) 0.45g of chloroauric acid solid containing crystal water is dissolved in water, configured into a chloroauric acid solution, and a few drops of hydrochloric acid are added dropwise to make the pH value of the chloroauric acid solution at 6.5, preventing it from decomposing; the chloroauric acid solution Add dropwise to the above ligand solution, stir magnetically for 0.5h to make it evenly mixed;

[0044] (3) Take 10.50g colloidal SiO 2 Place in a sealed plastic container, stir magnetically at 110°C for 1 hour, and then mix with the above ligand solution;

[0045] (4) 6.15g NaAlO 2 The solid was dissolved in deionized water, added dropwise to the ligand solution mixed with the silica colloidal solution, and magnetically stirred at 22°C for 2 hours to form a gel solution;

[0046] (5) The above gel solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com