Fabricated frame structure column-column bundled rebar connecting structure

A frame structure and connection structure technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of many connection joints, difficult installation, and multiple reinforcement configurations, so as to reduce connection joints, enhance anti-corrosion ability, reduce The effect of small hoisting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

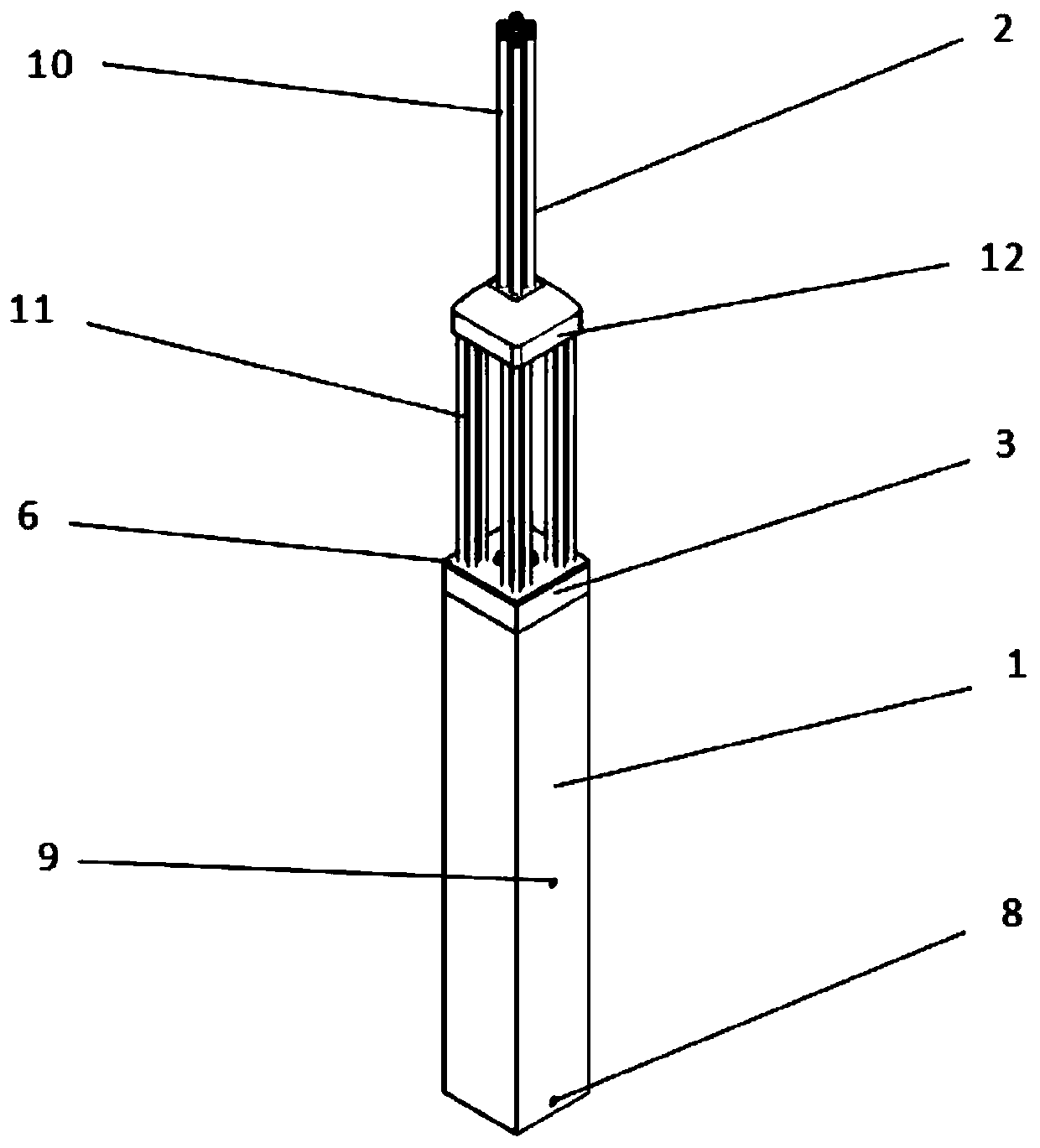

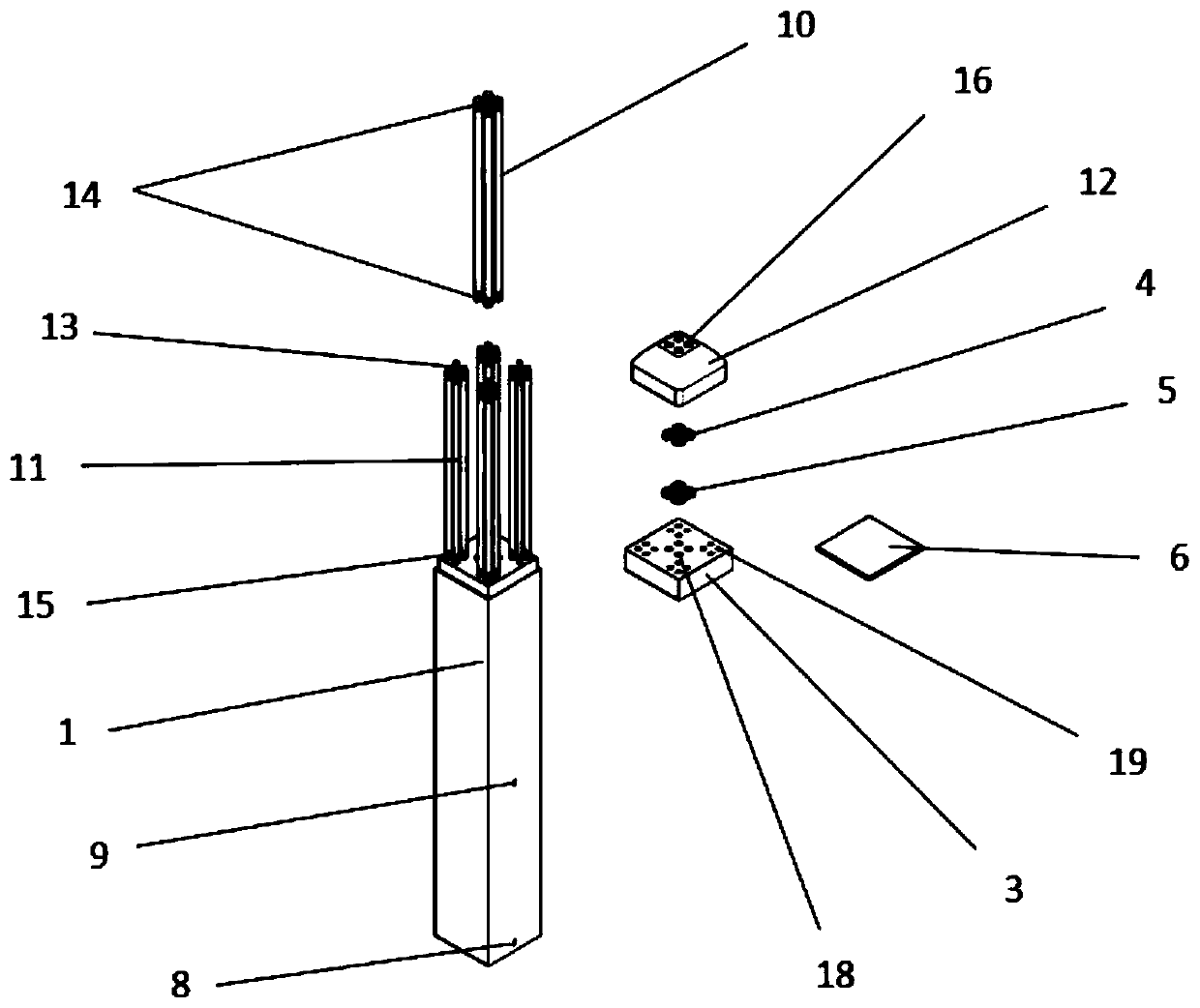

[0026] A prefabricated frame structure column-column bundled steel bar 2 connection structure, comprising a precast concrete column 1 and a clustered steel bar 2, the clustered steel bar 2 is anchored on the precast concrete column 1, and the precast concrete column 1 has a concave Cavity structure 7, the inner concave cavity structure 7 is installed with the cluster steel bar 2 anchored on the precast concrete column 1 installed in the lower layer; the upper end of the precast concrete column 1 is provided with an anchor seat 3 for installing the cluster steel bar 2, and the said The anchor base 3 is provided with a central round hole 18 and an outer peripheral threaded hole 19 , both of which are connected to the inner cavity structure 7 below the anchor base 3 .

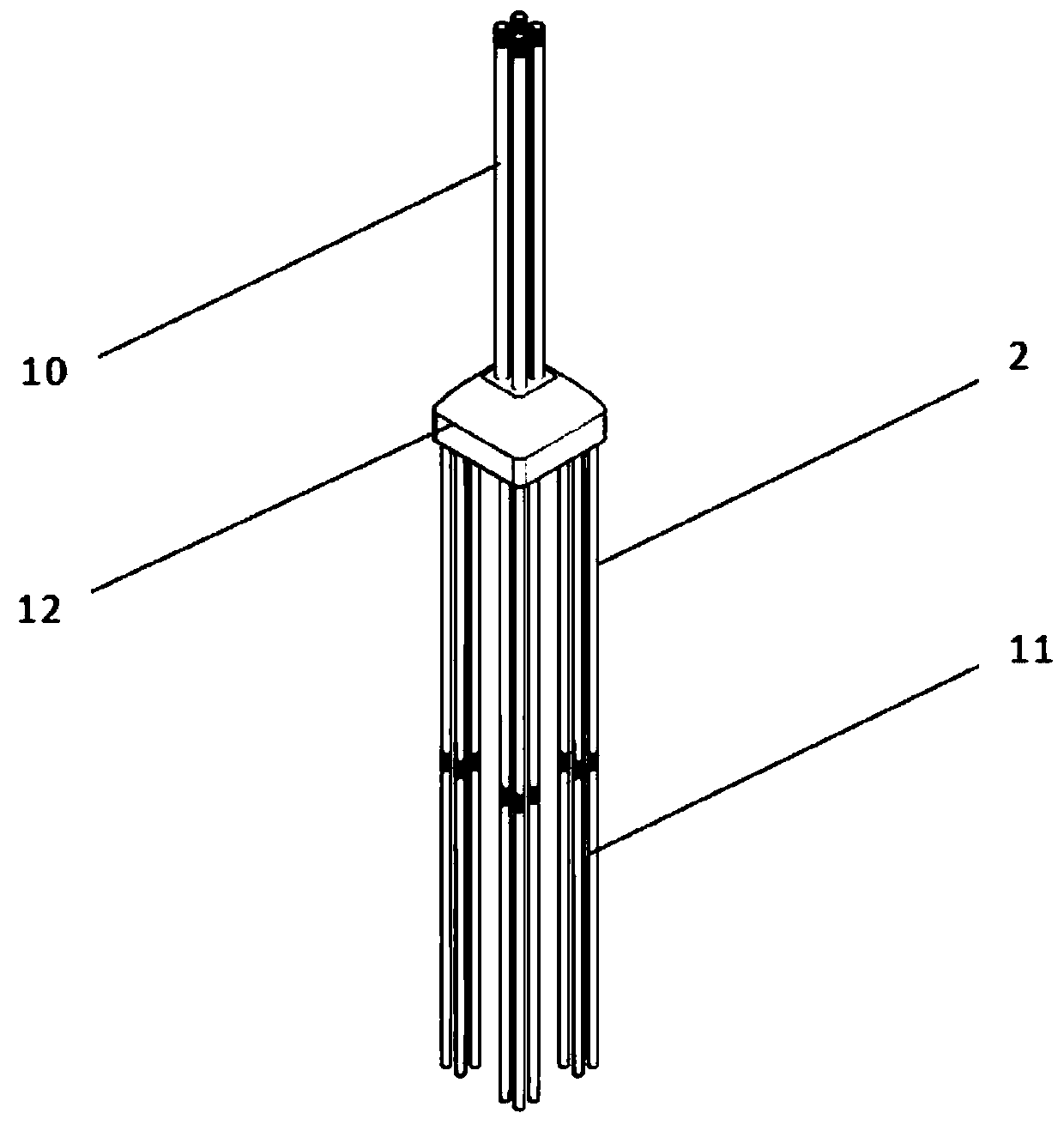

[0027] The clustered steel bar 2 includes an upper edge longitudinal bar 10, a lower anchoring longitudinal bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com