Longitudinal bar bundled pouring long through hole pre-cast shear wall and construction method thereof

A prefabricated shear force and construction method technology, which is applied to walls, buildings, building components, etc., can solve the problems of slow assembly construction progress, high cost, and heavy connection workload, so as to reduce construction cost, reduce connection joints, and ensure construction quality and structural safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

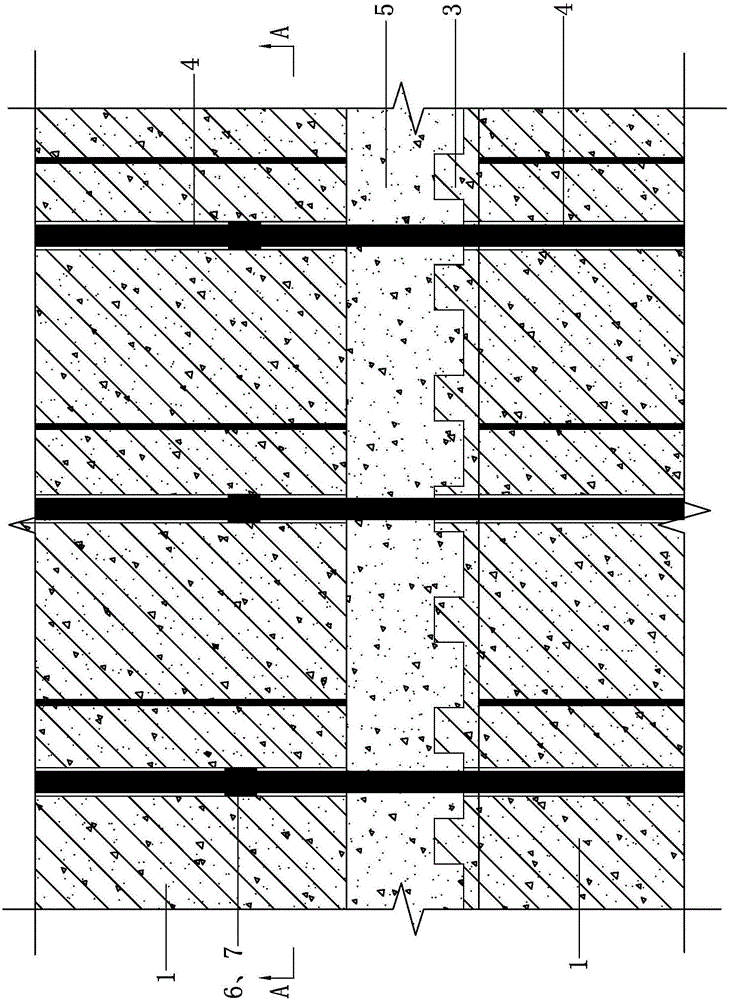

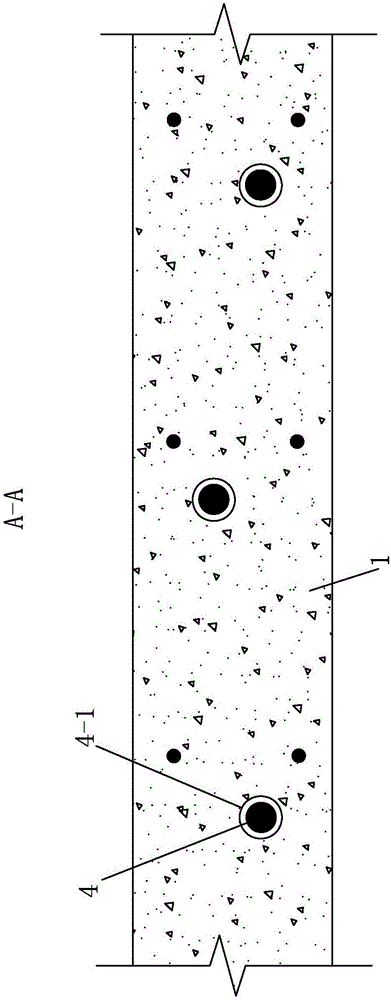

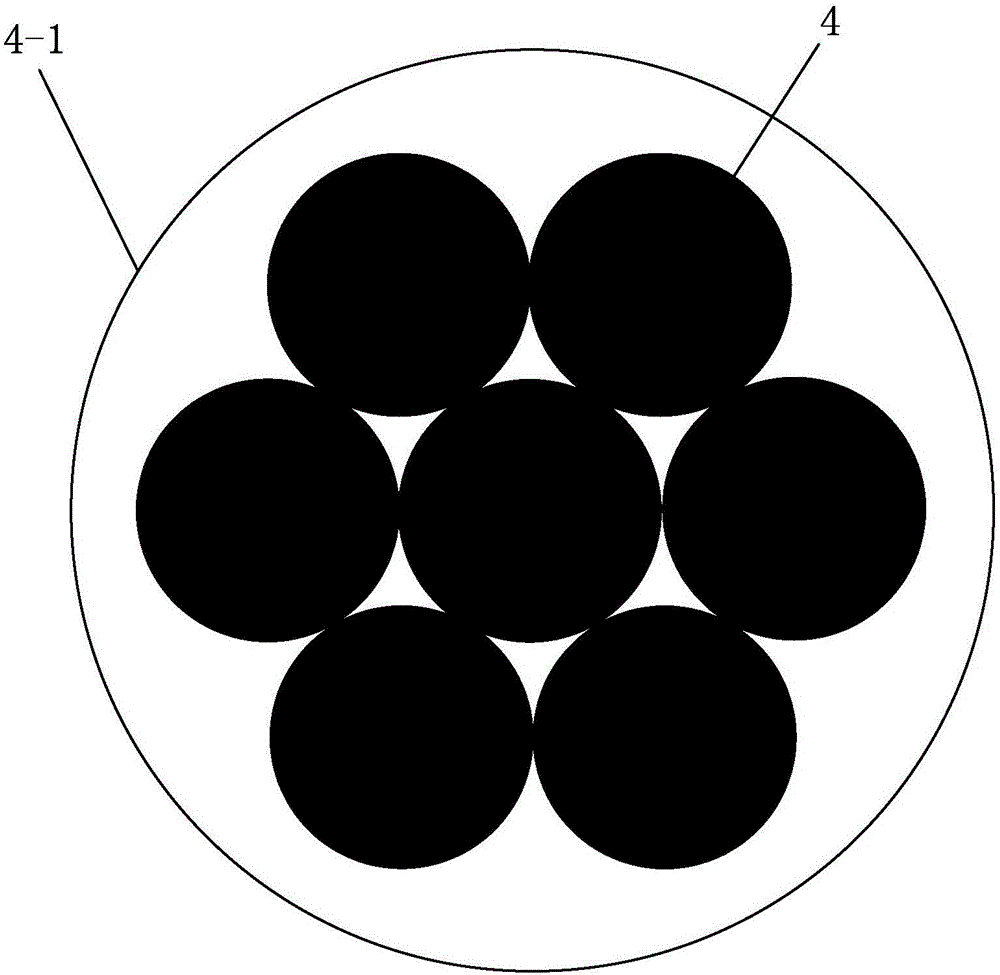

[0029] see Figure 1-Figure 3 As shown, the prefabricated shear wall poured with long holes after the longitudinal reinforcement is bundled includes N-layer prefabricated shear wall 1, M-layer prefabricated laminated ribbed floor slab 3, multiple groups of bundled longitudinal reinforcement 4 and concrete 5; where N, M It is a positive integer, M≥1, N=M+1;

[0030] Two adjacent layers of prefabricated shear walls 1 are vertically aligned and arranged, and a plurality of vertically arranged through-holes 4-1 are reserved respectively. The lower shear walls of adjacent two layers of prefabricated shear walls 1 The edge of the length direction is supported by a prefabricated laminated ribbed floor slab 3, and a group of bundled longitudinal reinforcements 4 are respectively arranged in the N bundled n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com