Prefabricated shear wall bundling steel bar connection structure by using total-fabricated horizontal joints

A technology of prefabricated shear and connection structures, applied in the direction of structural elements, walls, building components, etc., can solve the problems of difficult installation, many connection joints, and multiple reinforcement configurations, so as to reduce connection joints, enhance anti-corrosion ability, and better yield The effect of rear stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

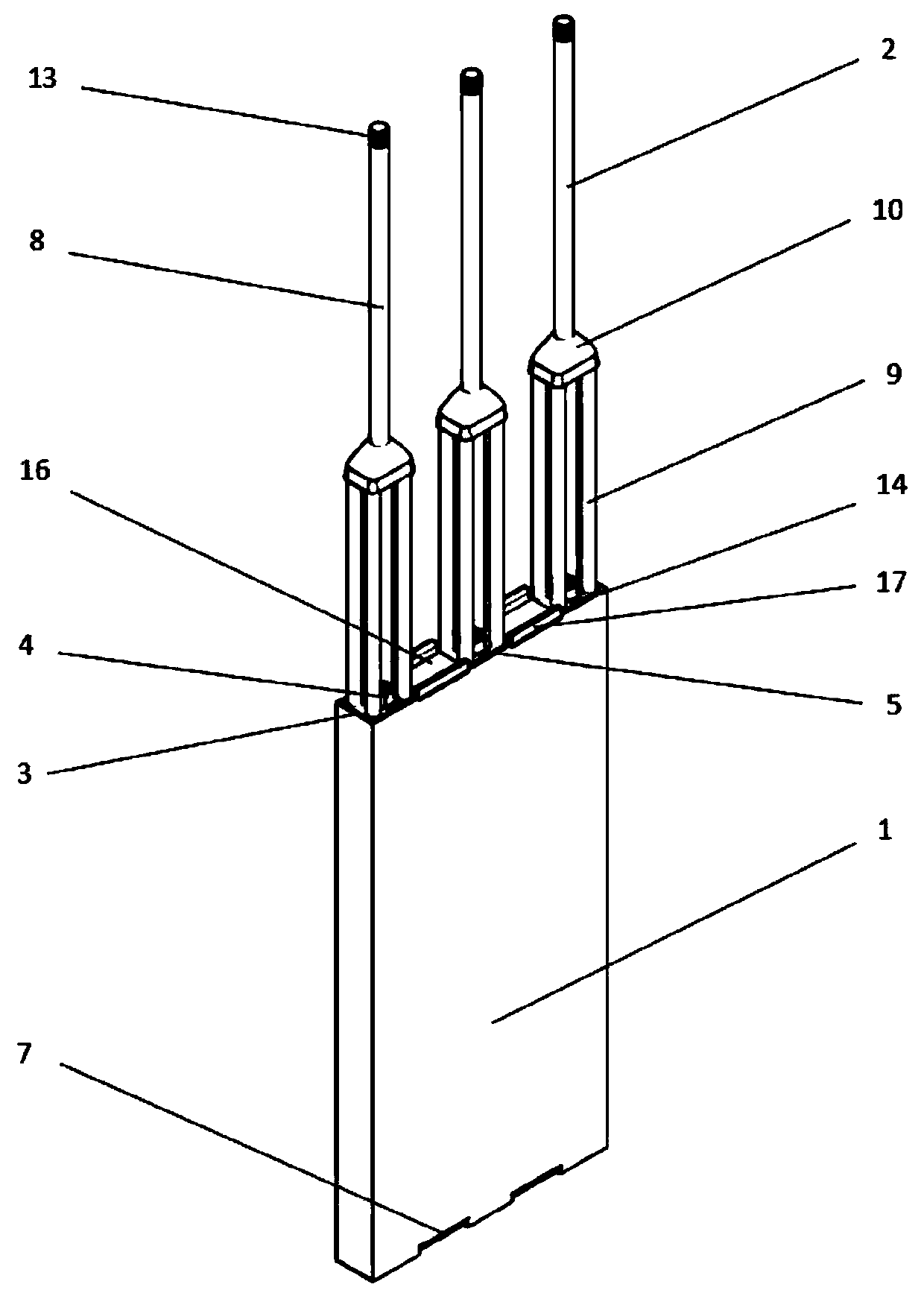

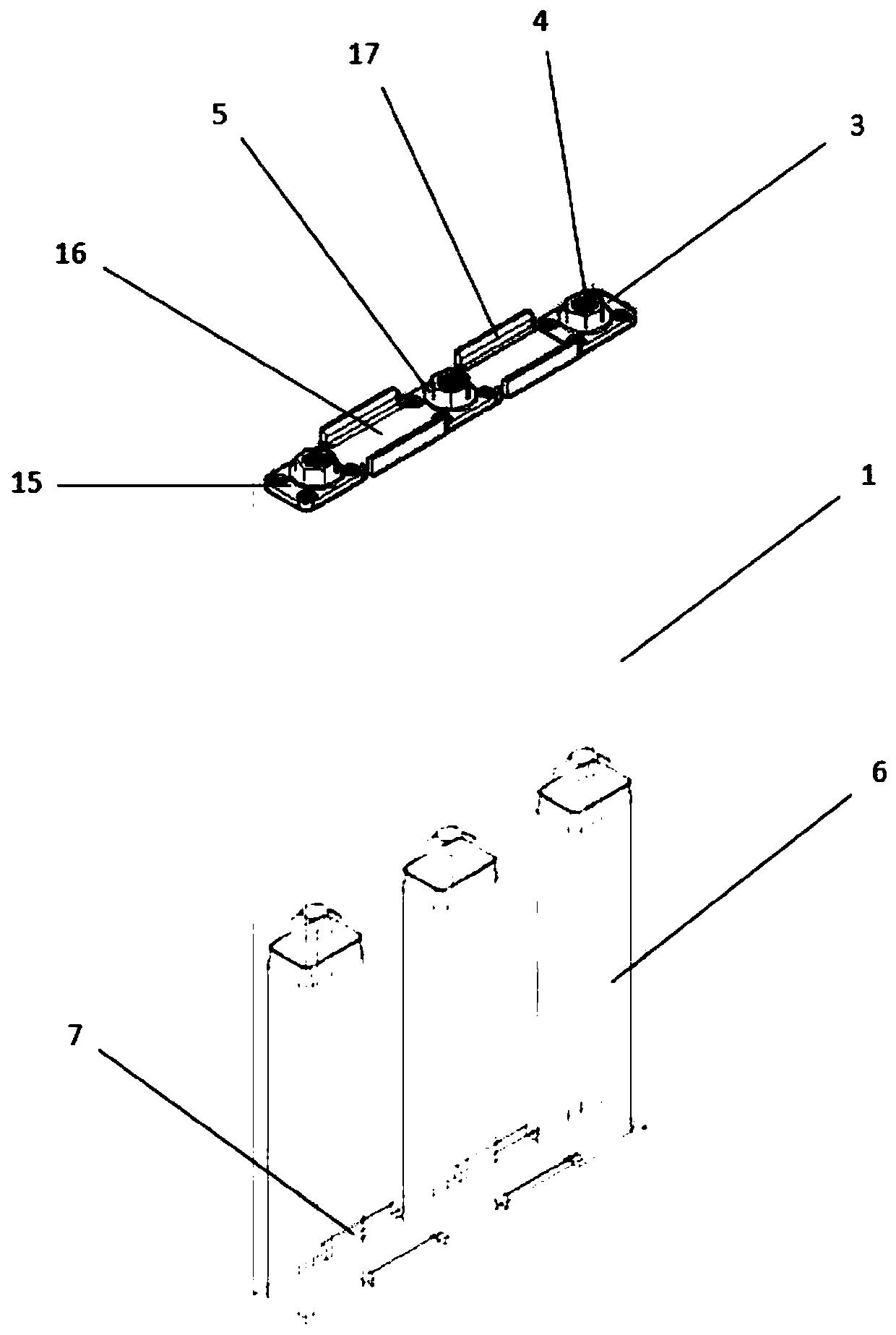

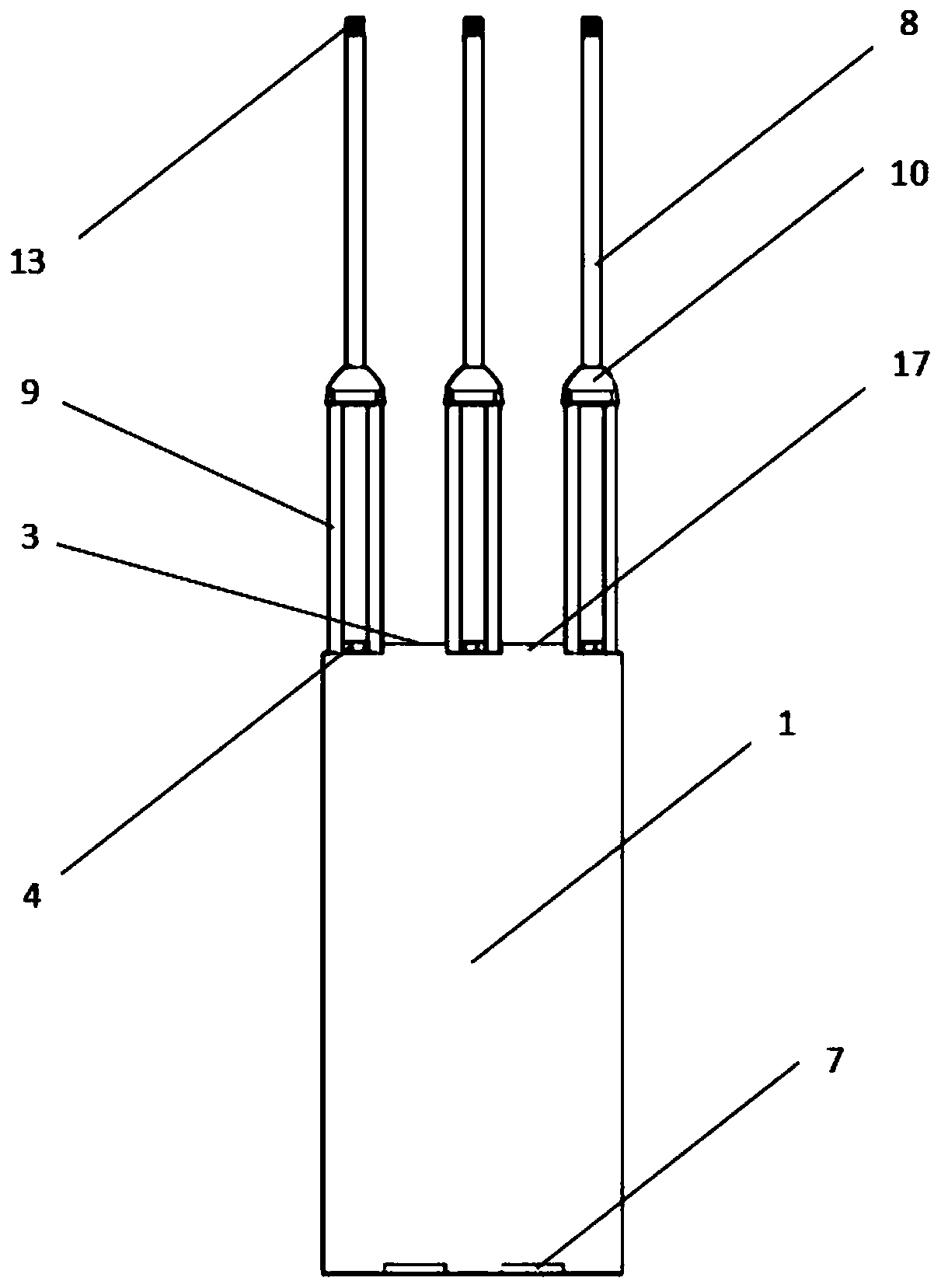

[0033] A prefabricated shear wall cluster reinforcement 2 connection structure using fully assembled horizontal joints, including a prefabricated shear wall body 1 and cluster reinforcement 2, the cluster reinforcement 2 is installed on the prefabricated shear wall body 1, the The prefabricated shear wall body 1 has a steel bar reserved installation cavity 6, and the bottom of the prefabricated shear wall body 1 has a reserved installation slot 7, and the lower prefabricated shear wall body is installed in the reserved installation slot 7. Steel bar; the steel connector 3 is pre-buried on the prefabricated shear wall body 1, and the bottom of the anchor plate is reserved for the installation cavity of the steel bar. The steel connector 3 includes an anchor plate 15, an auxiliary seat 16 and a card seat 17, The anchor plate 15 is pre-embedded in the upper part of the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com